21 care & maintenance – In-Situ TROLL 9500 Operators Manual User Manual

Page 146

141

Multi-Parameter

Water Quality TROLL

®

TROLL 9500 Operator’s Manual

0095110 rev. 007 01/09

21 CARE & MAINTENANCE

REPLACING BATTERIES

The MP TROLL 9500 uses—

s

optical dissolved oxygen sensor, and with a turbidity wiper

Use only Saft LSH-20 3.6V lithium D cells. Use of any

other lithium battery will void the product warranty.

Battery voltage and approximate percentage remaining is displayed

in the software interface when the instrument is connected to a PC.

Note: Due to the voltage supplied by two lithium D cells, the software

may report that the TROLL 9500 is operating on external power.

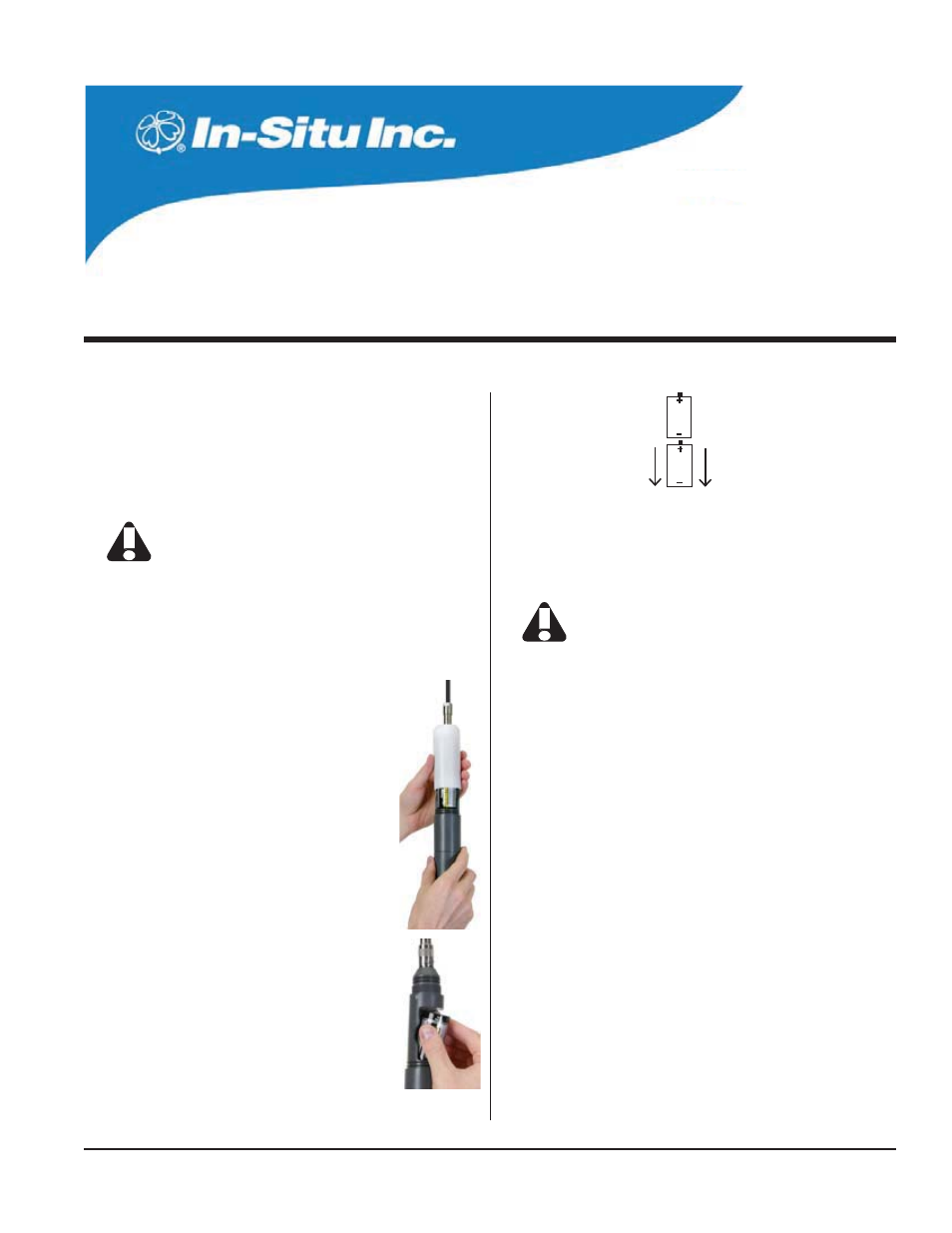

To replace batteries:

1. Unscrew and remove the white battery compart-

ment cover. If the cable is attached, slide the

battery compartment cover up onto the cable.

2. Press down slightly on the top battery to remove it,

or knock it out gently into your hand.

3. Tip the unit to slide the bottom battery out.

4. Insert the new batteries according to the dia-

gram on the inside of the battery compartment

(positive up for both).

5. Slide the white cover back down over the battery compartment and

hand-tighten to thread it to the instrument body.

Screw the cover down firmly to compress the o-rings and

create a waterproof seal. When properly assembled, the

o-rings will not be vsible.

6. At your next software connection in Win-Situ 4 or Pocket-Situ 4,

edit the device to update the battery information. (See “Editing the

Device Properties” in Section 4.)

O-RING SEALS

LUBRICATION

The Viton

®

o-rings used in the MP TROLL 9500 and other submersible

In-Situ instruments are crucial to insure the integrity of the water-

tight seal. We recommend that you inspect them each time they are

stressed (insertion/removal of sensors, attachment/removal of the

restrictor, battery replacement, etc.) for any indication of dirt, cracks,

tears, splitting, shredding, desiccation, and other damage. If the o-

rings are in good condition, apply silicone lubricant before re-assem-

bling the instrument. Remove excess lubricant with a lint-free tissue.

If the o-rings are damaged, they should be replaced, as described

below.

When lubricating the sensor o-rings, take special care to keep grease

away from the area around the connector at the bottom of the sen-

sors. Should lubricant get into this area, remove it with a clean cotton

swab.

Insert batteries negative side first,

positive side up