In-Situ PXD-461 Operators Manual User Manual

Instruction sheet, Calibration documentation, Installation

Instruction Sheet

Page 1 of 4

Calibration Documentation

Documents provided with the transducer describe In-Situ’s calibra-

tion process and list the transducer’s calibration coefficients (Linear-

ity, Scale, and Offset), which are also printed on the backshell dust cap.

Installation

Installation requires four steps, which may be performed in any

convenient order:

• Attach the cable

• Connect the cable to the data logger

• Install the transducer in the water

• Program the data logger to identify the transducer

Attach the Cable

1

Remove the protective caps from the backshell and the Quick-

Connect connector on the cable.

2

Slide back the sleeve of the Quick-Connect connector.

3

Align the tab in the transducer backshell with the slot inside the

cable connector.

4

Slide the two parts together and press tightly. They should slip

together easily, without forcing.

5

Tighten the locking sleeve hand-tight.

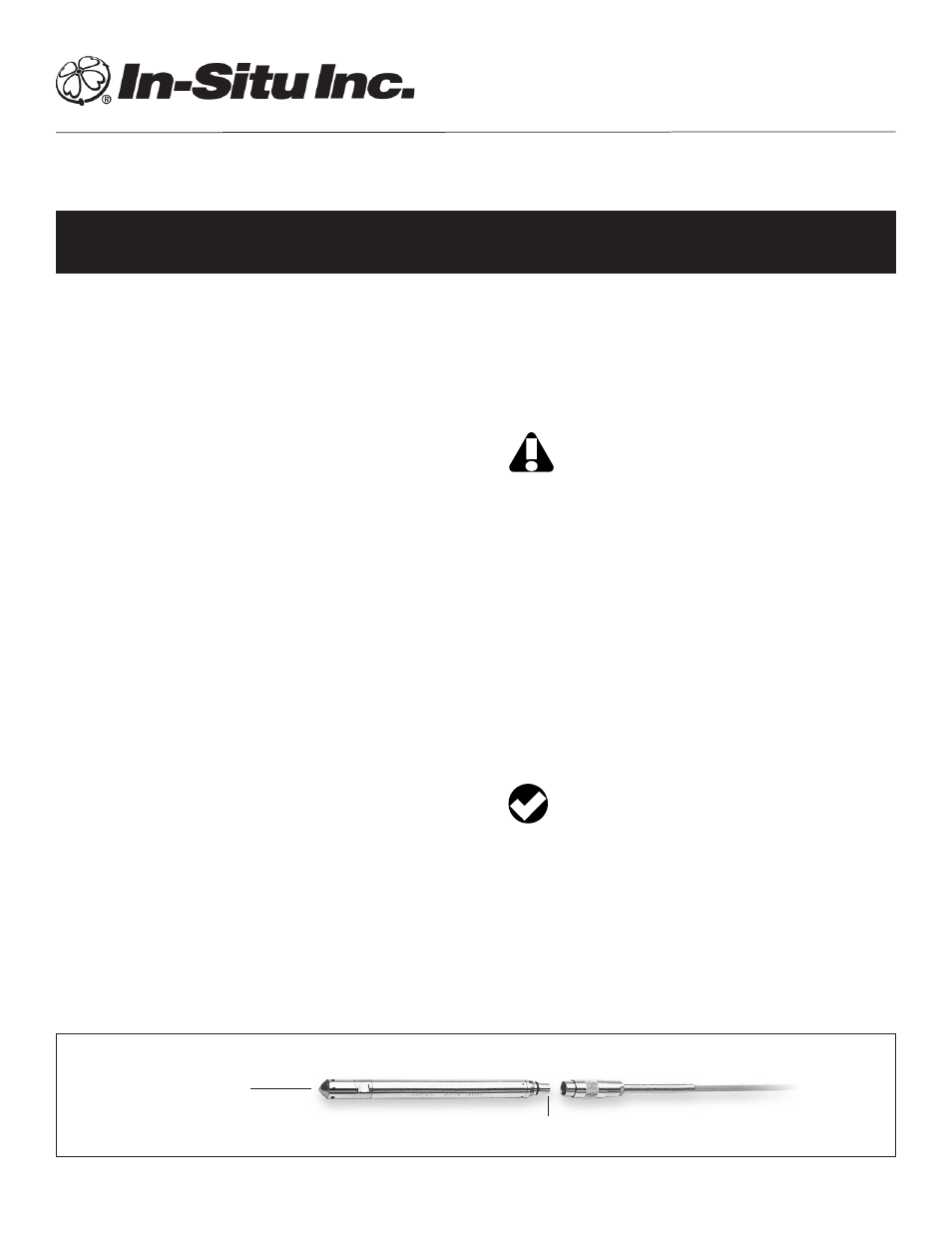

Pressure Transducers: PXD-261 & PXD-461

The only removable parts of the transducer are the nose cone

and cable. Do not take the body apart, as this may severely

damage the transducer and will void the warranty.

In-Situ’s PXD-261 and PXD-461 are fully submersible pressure

transducers for monitoring pressure or water level. They can be used

with In-Situ’s HERMIT

®

data loggers to collect fast, accurate time-

drawdown data from pump and slug tests. Small diameter permits

access to 1" wells. Removable nosecone and NPT threading allows

use in piping or conduit. Quick-Connect cable is easy to install, and

long cable lengths do not compromise accuracy.

Your transducer was carefully inspected before shipping and is ready

to operate out of the box. Check for any physical damage during

shipment. Notify In-Situ and file a claim with the carrier if there is

any such damage. If your transducer didn’t come as ordered, please

contact In-Situ immediately.

Operating Principle

A pressure transducer senses changes in pressure, measured in

pounds per square inch (PSI), exerted by a column of water or other

fluid above an internal strain gauge. This is translated electronically

to a 4-20 mA signal sent to a data logger. Software calibration coeffi-

cients unique to each transducer enable the logger to convert the 4-

20 mA output to meaningful results in the desired units.

PSIA and PSIG

PSIA stands for “pounds per square inch absolute,” measured with

respect to zero pressure. PSIA transducers measure all pressure forces

detected by the strain gauge, including atmospheric pressure.

PSIG stands for “pounds per square inch gauge,” measured with

respect to atmospheric pressure. PSIG transducers thus exclude the

atmospheric pressure component.

This difference may be represented by a simple equation:

P

gauge

= P

abs

- P

atmos

Don’t discard the caps. Set them aside for later use to

protect the contacts when the probe and cable are not in

use, and for convenient reference to the coefficients.

Quick-Connect

cable connector

Cable

Stainless steel nose cone,

removable for cleaning or for

installation using NPT threads

Backshell

Protective dust cap lists calibration coefficients

Stainless steel body, engraved

with model & serial number

PXD Pressure Transducers

(PXD-461 shown)