App.2-11, App. sc – Yokogawa 2-Wire Dual Channel Transmitter/Analyzer FLXA21 User Manual

Page 227

App.2-11

IM 12A01A02-01E

5th Edition : Oct. 31, 2013-00

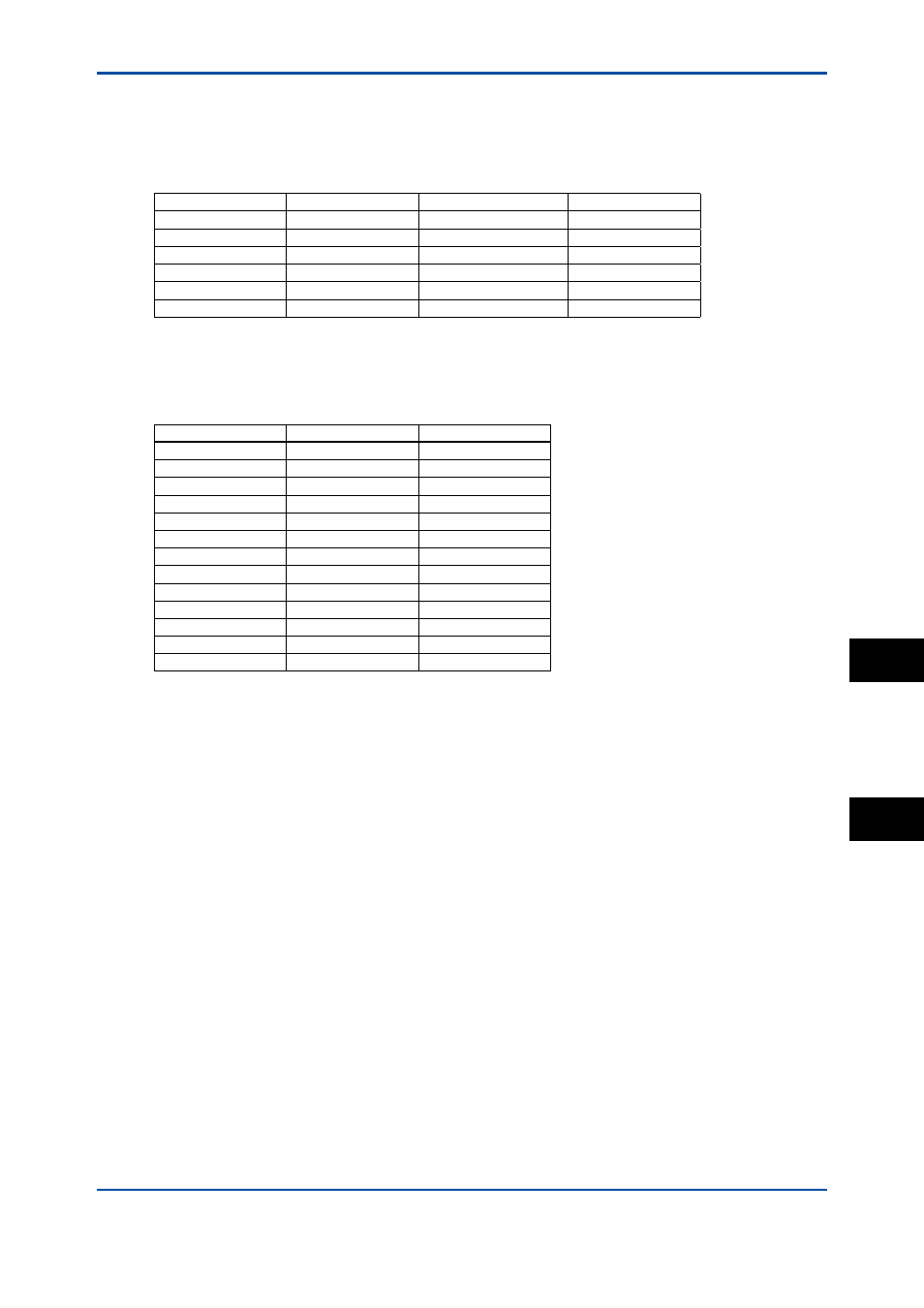

FLXA21 is programmed with the following table of conductivity of Potassium Chloride (KCl)

solutions at 25°C. This is used in the Automatic Cell Constant setting calibration feature. (See

chapter 9 on calibration) The table is derived from the Standards laid down in “International

Recommendation No. 56 of the Organisation Internationale de Métrologie Legale”.

Table 4 KCl values at 25 °C

Standard solution

mol/l

mg KCl/kg of solution

Conductivity

1.000 M KCl

1.0

71135.2

111.31 mS/cm

0.100 M KCl

0.1

7419.13

12.852 mS/cm

0.010 M KCl

0.01

745.263

1.4083 mS/cm

0.005 M KCl

0.005

373.29

0.7182 mS/cm

0.002 M KCl

0.002

149.32

0.2916 mS/cm

0.001 M KCl

0.001

74.66

0.1469 mS/cm

If it is more convenient, the user may make solutions from Sodium Chloride (NaCl or common

table salt) with the help of the following relationship table. This table is derived from the IEC norm

60746-3.

Table 5 NaCl values at 25 °C

Weight %

mg/kg

Conductivity

0.001

10

21.4 µS/cm

0.003

30

64.0 µS/cm

0.005

50

106 µS/cm

0.01

100

210 µS/cm

0.03

300

617 µS/cm

0.05

500

1.03 mS/cm

0.1

1000

1.99 mS/cm

0.3

3000

5.69 mS/cm

0.5

5000

9.48 mS/cm

1

10000

17.6 mS/cm

3

30000

48.6 mS/cm

5

50000

81.0 mS/cm

10

100000

140 mS/cm

For resistivity measurement the standard resistivity units of the calibration solution can be

calculated as follows:

R = 1000/G (kΩ•cm if G = µS/cm)

Example: 0.001% weight

R = 1000/21.4 = 46.7 kΩ•cm

n

Monitoring of Purified Water and WFI according to USP<645>

First published in the USP23 (The United States Pharmacopeia, ed. 23), the USP <645>

describes a procedure of measuring the conductivity of Purified Water and WFI (Water for

Injection) instead of the previous complicated monitoring procedure. This procedure consists

of three stages for measuring the conductivity of Purified Water and WFI. On the stage 1,

firstly the temperature of the water and the non-temperature-compensated conductivity of the

water are measured, and this conductivity is compared with the limit conductivity value of the

corresponding temperature directed by USP<645>. (Refer to Figure 3.) If the conductivity is

higher than the limit value, the procedure will proceed to the stage 2.

The FLXA21 has the limit values of USP<645> built in the firmware. When the error configuration

is set for this monitoring, the FLXA21 checks the non-temperature-compensated conductivity

with the limit value. If the conductivity is higher than the limit value, an error will be generated. A

safety margin to the limit value can be set on the FLXA21 to generate an error below limit value.

(Refer to the section 7.3.)

When the safety margin is set at 20%, for example, an error will be generated when the non-

temperature-compensated conductivity goes higher than the 80% of the limit value at all

temperatures. For example, if the temperature is 64 ºC. and the safety margin is set at 20%,

then an error will be generated at 0.8 x 2.2 μS/cm. = 1.76 μS/cm. (2.2 μS/cm is the USP<645>

limit value at 64ºC). In resistivity mode, an error will be generated at an non-temperature-

compensated resistivity of 0.568 MΩ (=1/1.76 μS/cm).

App.

SC