Lincoln Electric IM10178 POWER FEED 84 U.I. CONTROL BOX User Manual

Page 66

B-30

OPERATION

POWER FEED 84, POWER FEED 84 DUAL

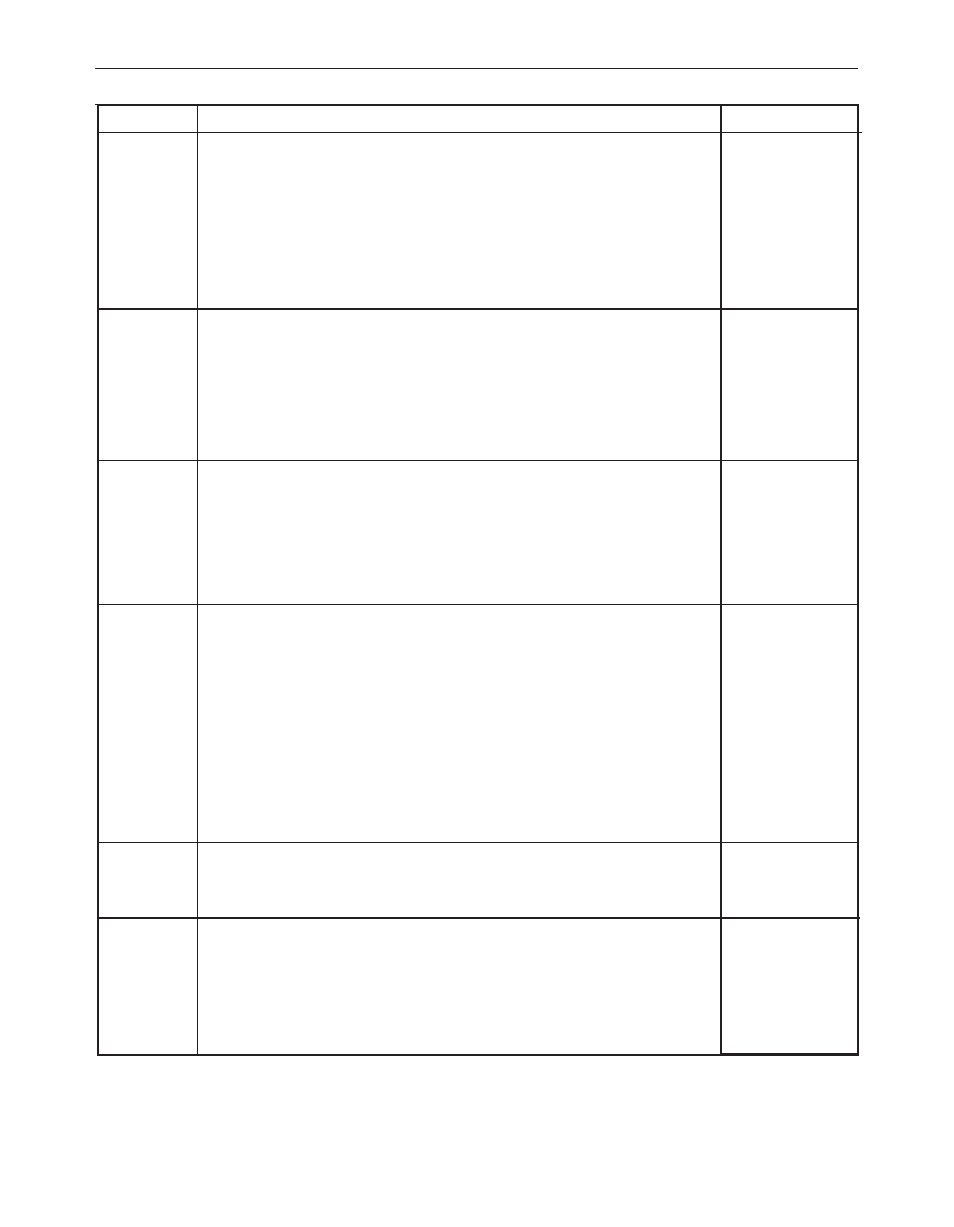

Parameter

Name and Description

P.18

Wire Drive Gear Ratio

This option selects the Wire Drive Gear Ratio that will be used. The possible selectable values are read

from the Wire Drive on startup. For semi-automatic systems, if the feedhead board has dip switches, this

option does not appear in the menu. Gear ratio can be selected using the dip switches.

On dual-head PF84 Feeders, a different setting can be used for each head. The operator will be prompted

to select which head to edit before the setting can be changed.

Note: Changing this value will cause the system to reset.

P.19

Wire Drive Direction

Used to select the wire drive “Forward” direction for single wire drive feeders. If the wire drive is

reassembled to the left side, the direction must change.

A

→ B = Wire drive assembled on the right hand side (default)

B

→ A = Wire drive assembled on the left hand

P.20

Display Trim as Volts Option

This option determines how trim is displayed.

False = The trim is displayed in the format defined in the weld set (default).

True = All trim values are displayed as a voltage.

Note: This option may not be available on all machines. The power source must support this functionality,

or this option will not appear in the menu.

P.22

Arc Start/Loss Error Time

This option can be used to optionally shut off output if an arc is not established, or is lost for a specified

amount of time.

Error 269 will be displayed if the machine times out. If the value is set to OFF, machine output will not be

turned off if an arc is not established nor will output be turned off if an arc is lost. The trigger can be used

to hot feed the wire (default). If a value is set, the machine output will shut off if an arc is not established

within the specified amount of time after the trigger is pulled or if the trigger remains pulled after an arc

is lost. This is disabled while welding in Stick, TIG or Gouge. To prevent nuisance errors, set Arc

Start/Loss Error Time to an appropriate value after considering all welding parameters (run-in wire feed

speed, weld wire feed speed, electrical stick out, etc). To prevent subsequent changes to Arc Start/Loss

Error Time, the setup menu should be locked out by setting Preference Lock = Yes using the Power Wave

Manager software.

P.24

Push Pull Type

Allows operator to choose the Prince option if welding with a Prince Push Pull gun. This gun requires

unique settings to run at the correct WFS.

P.27

Language Select

Selects which language will be displayed on the User Interface.

English (Default)

Italiano

Deutsch

Francais

Polski

Espanol

USER DEFINED PARAMETERS

Range

A→ B

B→ A

False,True

Default

Prince

English,

Italiano,

Deutsch,

Francais,

Polski,Espanol