Lincoln Electric IM10178 POWER FEED 84 U.I. CONTROL BOX User Manual

Page 37

B-1

OPERATION

The serviceability of a product or structure utilizing the

welding programs is and must be the sole responsibility of

the builder/user. Many variables beyond the control of The

Lincoln Electric Company affect the results obtained in

applying these programs. These variables include, but are not

limited to, welding procedure, plate chemistry and

temperature, weldment design, fabrication methods and

service requirements. The available range of a welding

program may not be suitable for all applications, and the

build/user is and must be solely responsible for welding

program selection.

poWer up seQuence

1. The contactor drive energizes the contactor to match the

active wire drive. The LED for the active wire drive

illuminates.

2. Settings of the feeder before the last power-down are

restored – wire feed speed, voltage, trigger type,

procedure, etc.

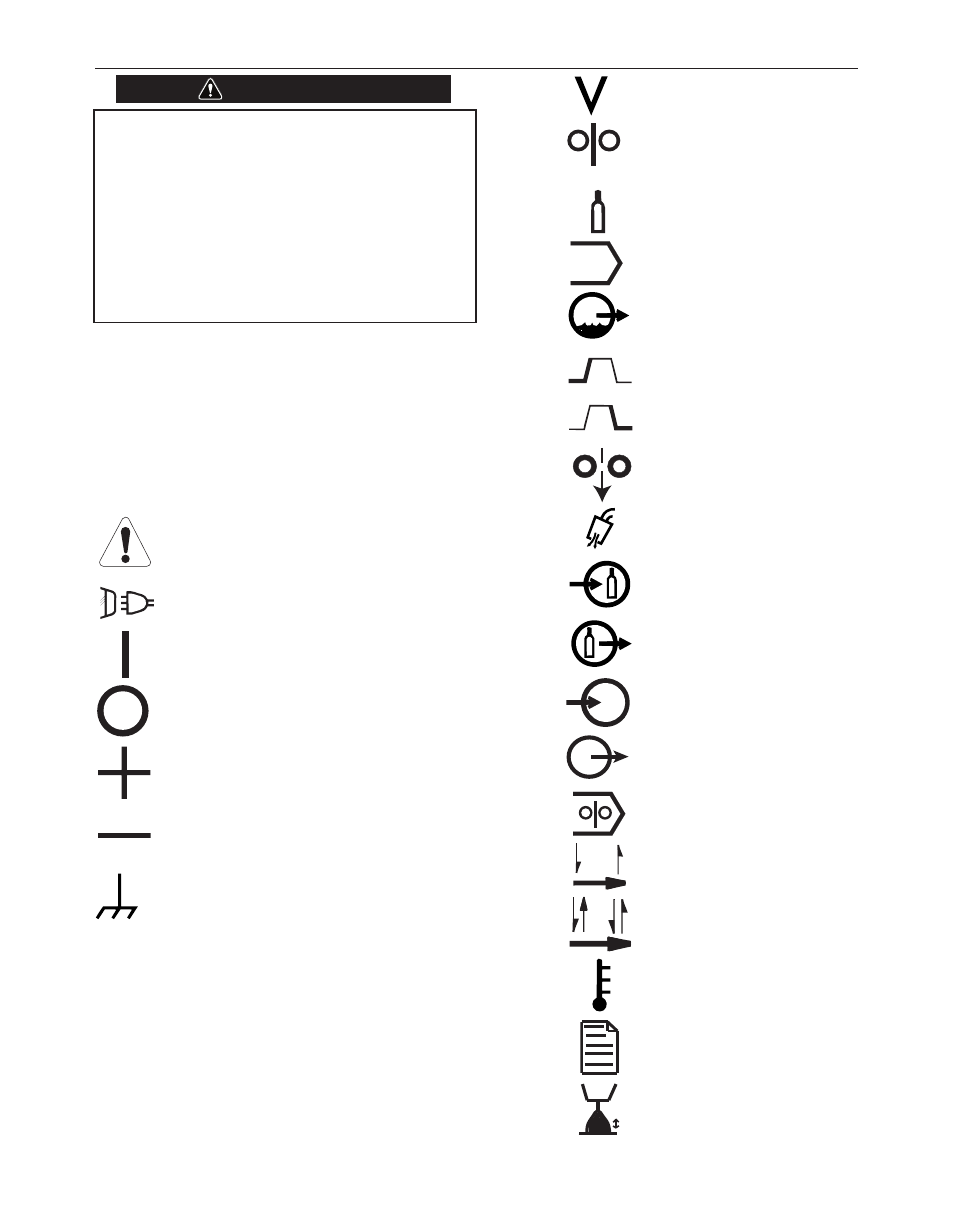

POWER FEED 84, POWER FEED 84 DUAL

ON

OFF

WIRE FEEDER

SHIELDING GAS

MENU

WAVE CONTROL

ARC END

PARMETERS

ARC START

PARMETERS

COLD FEED

GAS PURGE

SHIELDING GAS

INLET

SHIELDING GAS

OUTLET

M

MEMORy SAVED

M

MEMORy RECALL

WIRE DRIVE

SELECTION

2-STEP TRIGGER

4-STEP TRIGGER

THERMAL

SET-UP MENU

TRIM

WELDING AMPERAGE

WELDING VOLTAGE

POSITIVE OUTPUT

NEGATIVE OUTPUT

INPUT POWER

INPUT VOLTAGE

INPUT CURRENT

OUTPUT CURRENT

CHASSIE GROUND

WARNING OR

CAUTION

U1

I1

I2

A

graphic sYMbols ThaT appear on poWer feed 84,

poWer feed 84 dual or in This Manual

WARNING