Weld cables, standard – Lincoln Electric IM10178 POWER FEED 84 U.I. CONTROL BOX User Manual

Page 32

A-25

INSTALLATION

POWER FEED 84, POWER FEED 84 DUAL

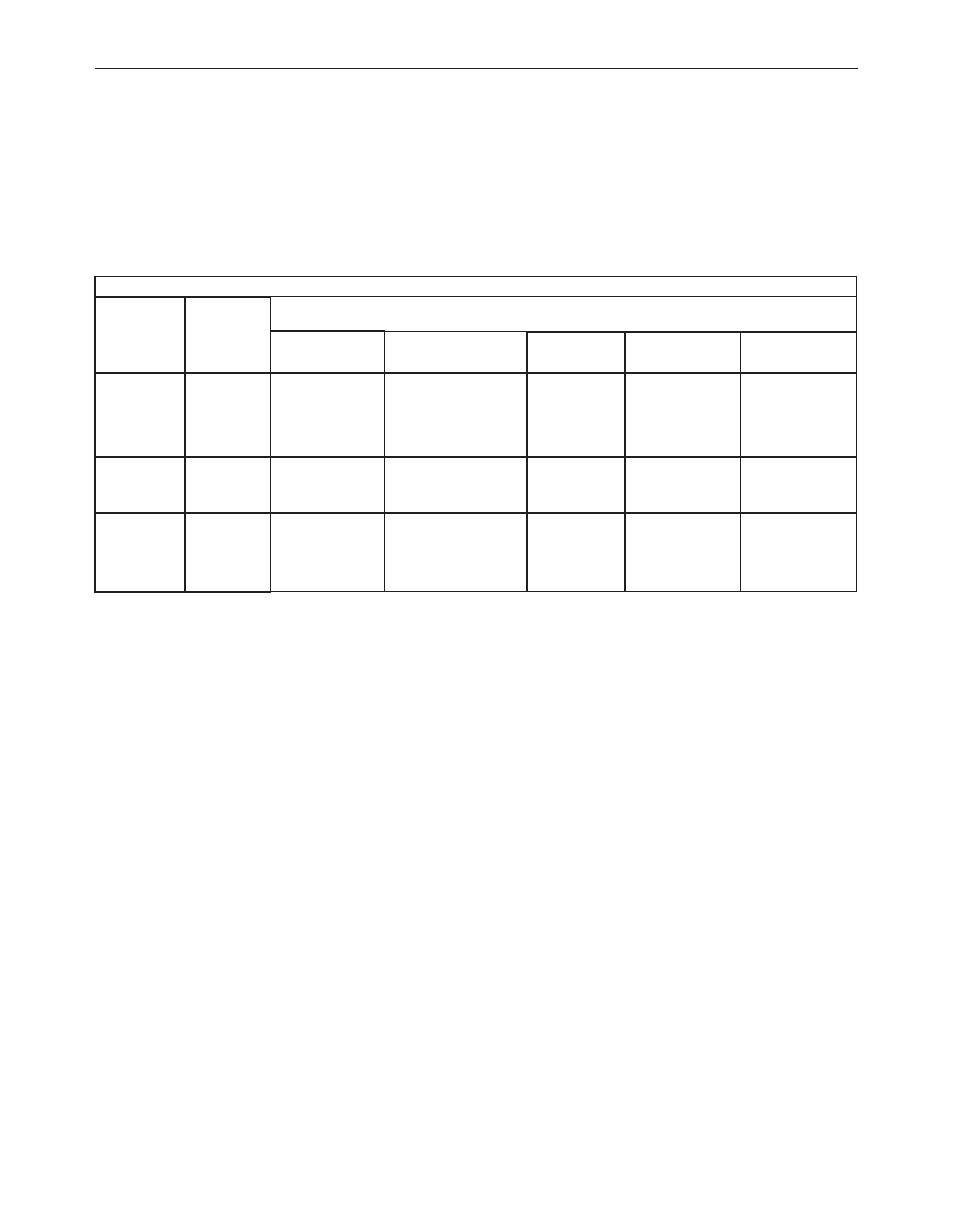

Weld cables, sTandard

Table A.2 has copper cable sizes recommended for different currents

and duty cycles. Lengths stipulated are the distance from the welder

to work and back to the welder again. Cable sizes are increased for

greater lengths primarily for the purpose of minimizing cable drop.

negative electrode polarity

The Power Feed 84 ships from the factory configured for electrode

positive polarity. See P.81 in the

operations section (Set-Up menu)

to select negative polarity welding.

**Tabledvaluesareforoperationatambienttemperaturesof104°F(40°C)andbelow.Applicationsabove104°F(40°C)mayrequirecables

largerthanrecommended,orcablesratedhigherthan167°F(75°C).

RECOMMENDED CABLE SIZES (RUBBER COVERED COPPER - RATED 167°F or 75°C)**

CABLESIZESFORCOMBINEDLENGTHSOFELECTRODEANDWORKCABLES

AMPERES

200

200

225

225

250

250

250

250

300

325

350

400

400

500

PERCENT

DUTY

CYCLE

60

100

20

40&30

30

40

60

100

60

100

60

60

100

60

0 to 50Ft.

(0 to15M)

2

2

4or5

3

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

50 to 100Ft.

(15 to 30M)

2

2

3

3

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

100 to 150 Ft.

(30 to 46M)

2

2

2

2

2

1

1

1

1

2/0

2/0

2/0

3/0

3/0

150 to 200 Ft.

(46 to 61M)

1

1

1

1

1

1

1

1

1/0

2/0

2/0

3/0

3/0

3/0

200 to 250 Ft.

(61 to 76M)

1/0

1/0

1/0

1/0

1/0

1/0

1/0

1/0

2/0

3/0

3/0

4/0

4/0

4/0

TABLE A.2