Lincoln Electric IM10178 POWER FEED 84 U.I. CONTROL BOX User Manual

Page 64

B-28

OPERATION

POWER FEED 84, POWER FEED 84 DUAL

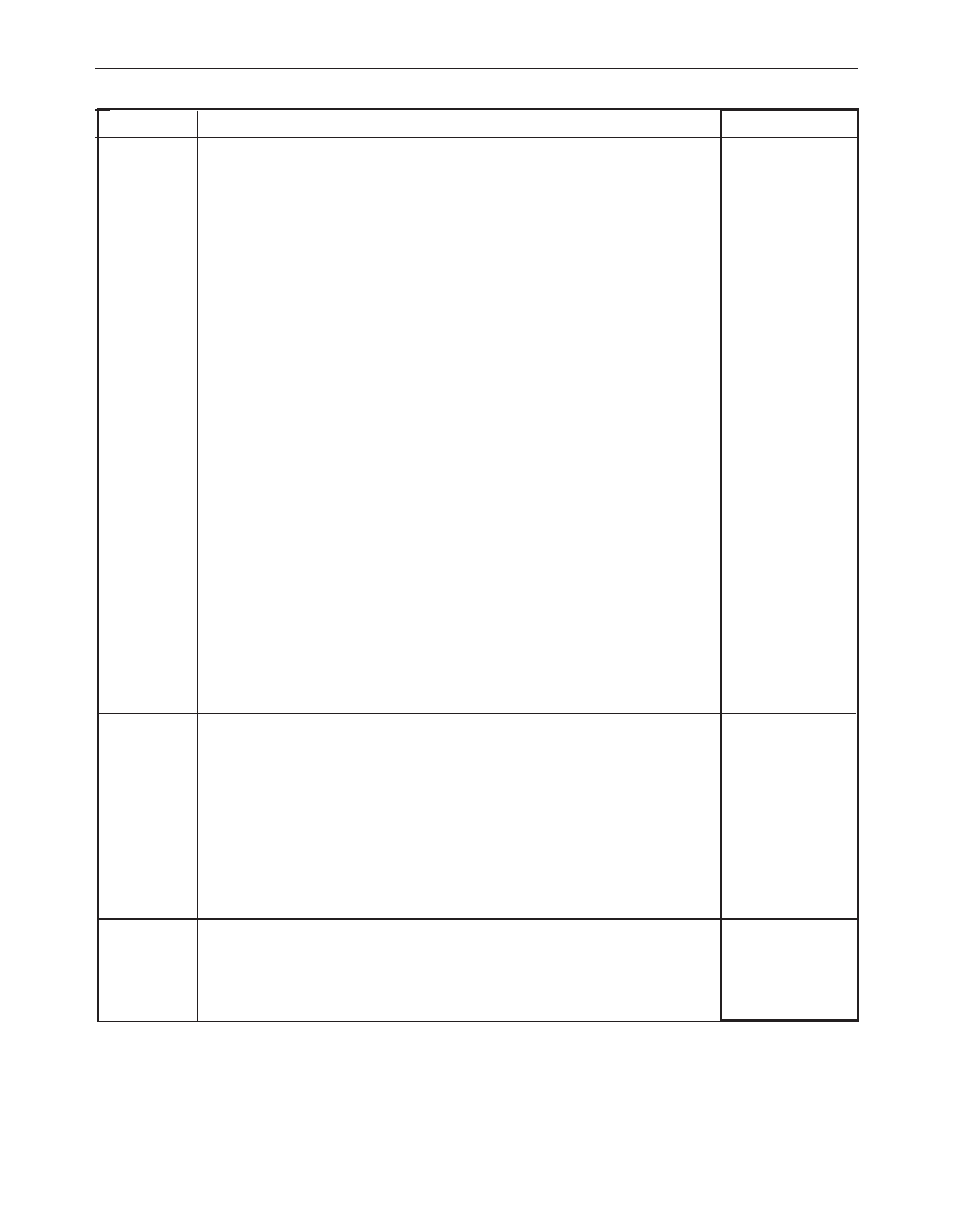

Parameter

Name and Description

P.8

TIG Gas Control

This option allows control over which gas solenoid actuates while

TIGwelding.

"Valve(manual)"=NoMIGsolenoidwillactuatewhileTIGwelding,

gasflowismanuallycontrolledbyanexternalvalve.

"Solenoid(auto)=TheMIGsolenoidwillturnonandoffautomatical-

lywhileTIGwelding.

"FeederSolenoid"=Theinternal(feeder)MIGsolenoidwillturnon

andoffautomaticallywhileTIGwelding.

"PwrSrcSolenoid"=NotapplicabletoPWC300.Anygassolenoid

connected to the power source will turn on and off automatically

while TIG welding. This selection will not appear in the list if the

powersourcedoesnotsupportagassolenoid.

Notes:PreflowisnotavailablewhileTIGwelding.Postflowisavail-

able - the same postflow time will be used in MIG and TIG.

Whenmachineoutputon/offiscontrolledviatheupperright

knob, gas flow will not start until the tungsten touches the

work.Gasflowwillcontinuewhenthearcisbrokenuntilthe

Postflow time expires. When machine output on/off is con-

trolled via an arc start switch or foot Amptrol, gas will begin

flowingwhentheoutputisturnedonandwillcontinueflowing

untiltheoutputisturnedoffandthePostflowtimeexpires.

IfadedicatedTIGgassolenoidisinstalled,asintheAdvancedAC

Module, all TIG gas control will use that solenoid and this menu

optionwillbeirrelevant.

P.9

Crater Delay

ThisoptionisusedtoskiptheCratersequencewhenmakingshort

tackwelds.Ifthetriggerisreleasedbeforethetimerexpires,Crater

willbebypassedandtheweldwillend.Ifthetriggerisreleasedafter

the timer expires, the Crater sequence will function normally (if

enabled).

On dual-head Power Feed 84 Feeders, a different setting can be

used for each head. The operator will be prompted to select which

headtoeditbeforethesettingcanbechanged.

P.14

Reset Consumable Weight

Usethisoptiontoresettheinitialweightoftheconsumablepackage.PresstheRightButtonto

reset the consumable weight. This option will only appear with systems using Production

Monitoring.

USER DEFINED PARAMETERS

Range

Valve(manual),

Feeder

Solenoid,

PwrSrc

Solenoid