Mounting the base unit, Blk red shld blk red s l shld blk s l shld, Relay 1 relay 2 enter – GF Signet 8900 Multi-Parameter Controller User Manual

Page 10: Din standard

10

Signet 8900 Multi-Parameter

5. Mounting the Base Unit

The 8900 may be mounted in a panel, on a wall, or on virtually

any surface including shelves, racks and pipes. All methods of

mounting the 8900 make use of the Signet Quick-clip for holding

the instrument securely in place. This unique clip eliminates the

hassle of locating and drilling holes for mounting screws.

If the 8900 will be mounted in a panel, plug-in modules may be

installed either before or after the base unit is mounted. If an

accessory Wall Mount Bracket will be used, fi rst install plug-in

modules.

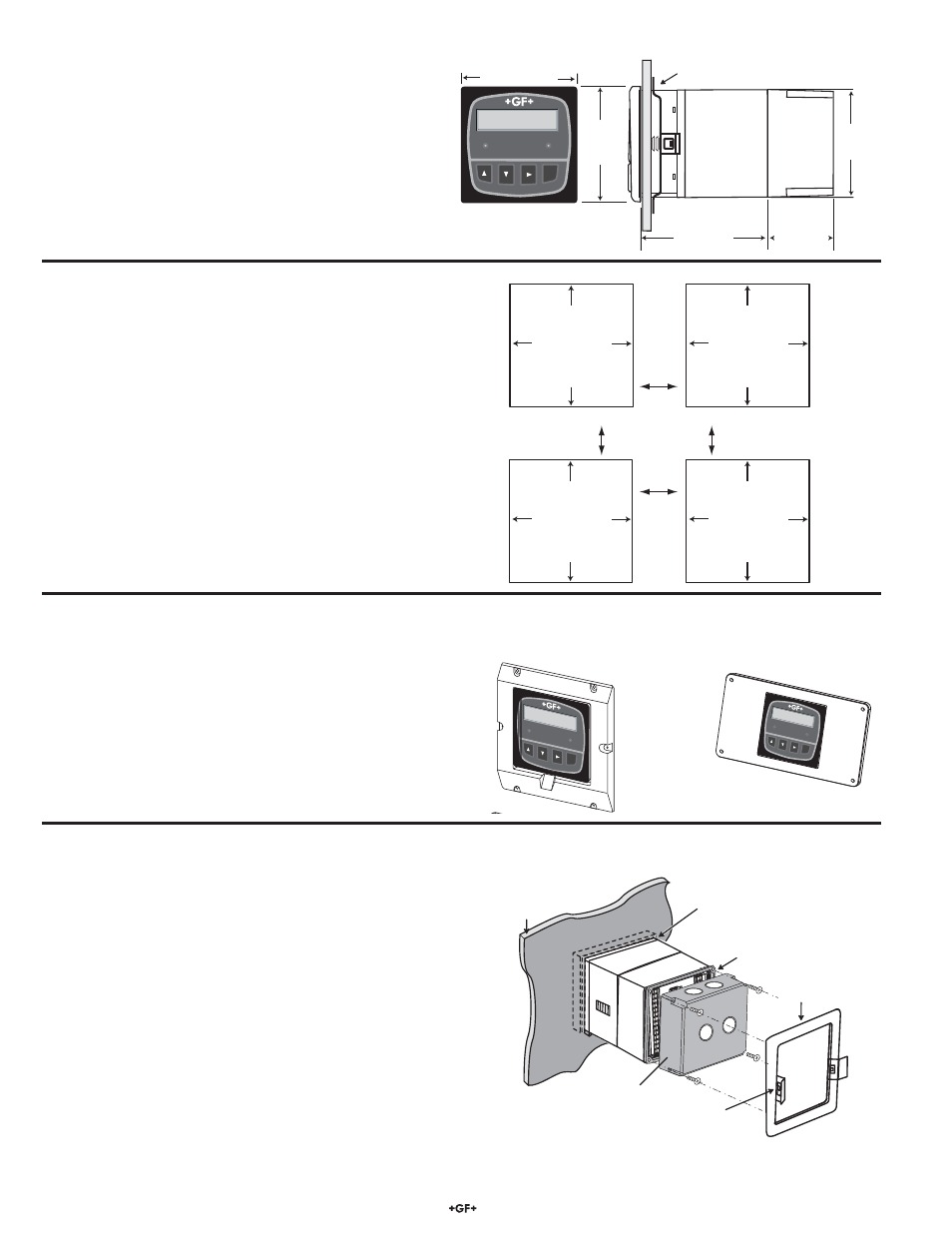

5.1 Panel Mounting

•

The 8900 enclosure conforms to the ¼-DIN standard, which

requires a panel opening of 92 mm x 92 mm (3.6 in. x 3.6 in.).

•

¼-DIN punches are available and recommended for creating

clean, precise openings quickly and easily in most instrument

panels.

•

Alternatively, a jigsaw or other cutting tool may be used.

An adhesive template is provided to help guide the cutting

process.

•

Recommended minimum clearance on all sides between

instruments and panel edges is 25 mm (1 in.) as illustrated.

•

Use an appropriate fi le as necessary to shape and size the

opening, and to remove burrs.

123 mm/

4.85 in.

56 mm/

2.21 in.

Splashproof

Rear Cover

(accessory)

96 mm/3.78 in.

96 mm/

3.78 in.

92 mm/

3.62 in.

Quick-clip

mounting

bracket

Multi-Parameter

Controller

C1 2.50 µS/cm

F2 58.43 GPM

Relay 1

Relay 2

ENTER

Multi-Parameter

Contro

ller

Relay 1

Relay 2

ENTER

C1 23.45 µS/cm

L2 -16.58 ft

Quick-clip

gasket on

front side

of panel

3-8050.395

Splashproof

rear cover

panel

terminals

mounting

bracket

O

U

T

2 O

U

T

1

P

O

W

E

R

C

O

M

M

P

O

R

T

/

O

U

T

4

O

U

T

3

R

E

LA

Y

2

R

E

L

A

Y

1

R

E

L

A

Y

4 R

E

L

A

Y

3

S

E

N

S

O

R

IN

P

U

T

S

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

+

-

+

-

N

L

+

-

BLK

RED

SHLD

BLK

RED

S L

SHLD

BLK

S L

SHLD

+

-

+

-

3

3

AC ONL

Y

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

minimum

clearance

25 mm

(1 in.)

To install 8900 in a panel:

1. Slide the 8900 into the opening from the front of the panel.

Ensure the Front Face Panel Gasket is properly seated

against the panel and around the instrument case.

2. Slide the Quick-clip mounting bracket over the back of the

instrument as illustrated. The Quick-clips will snap into

engagement with the molded latches on the side of the

instrument. Press the bracket against the inside of the panel

to secure the instrument fi rmly in place.

•

To remove, press the Quick-clips outward while pulling

the bracket away from the instrument panel. DO NOT

ALLOW THE INSTRUMENT TO FALL FORWARD OUT

OF THE PANEL OPENING! It may be necessary/helpful to

temporarily secure the instrument from the front with tape,

etc.

3-5000.399 Panel adapter,

5 in. x 5 in. to ¼-DIN

3-8050.392 Panel adapter,

½-DIN to ¼-DIN

Multi-Parameter

Controller

Relay 1

Relay 2

ENTER

C1 23.45 µS/c

m

L2 -16.58 ft

•

Two panel adapter accessories are available for installing the

8900 into panels with existing cutouts larger than the

1

/

4

DIN

standard.