GF Signet 9900 H COMM Module User Manual

Instruction sheet, Signet 9900 h comm module, Introduction

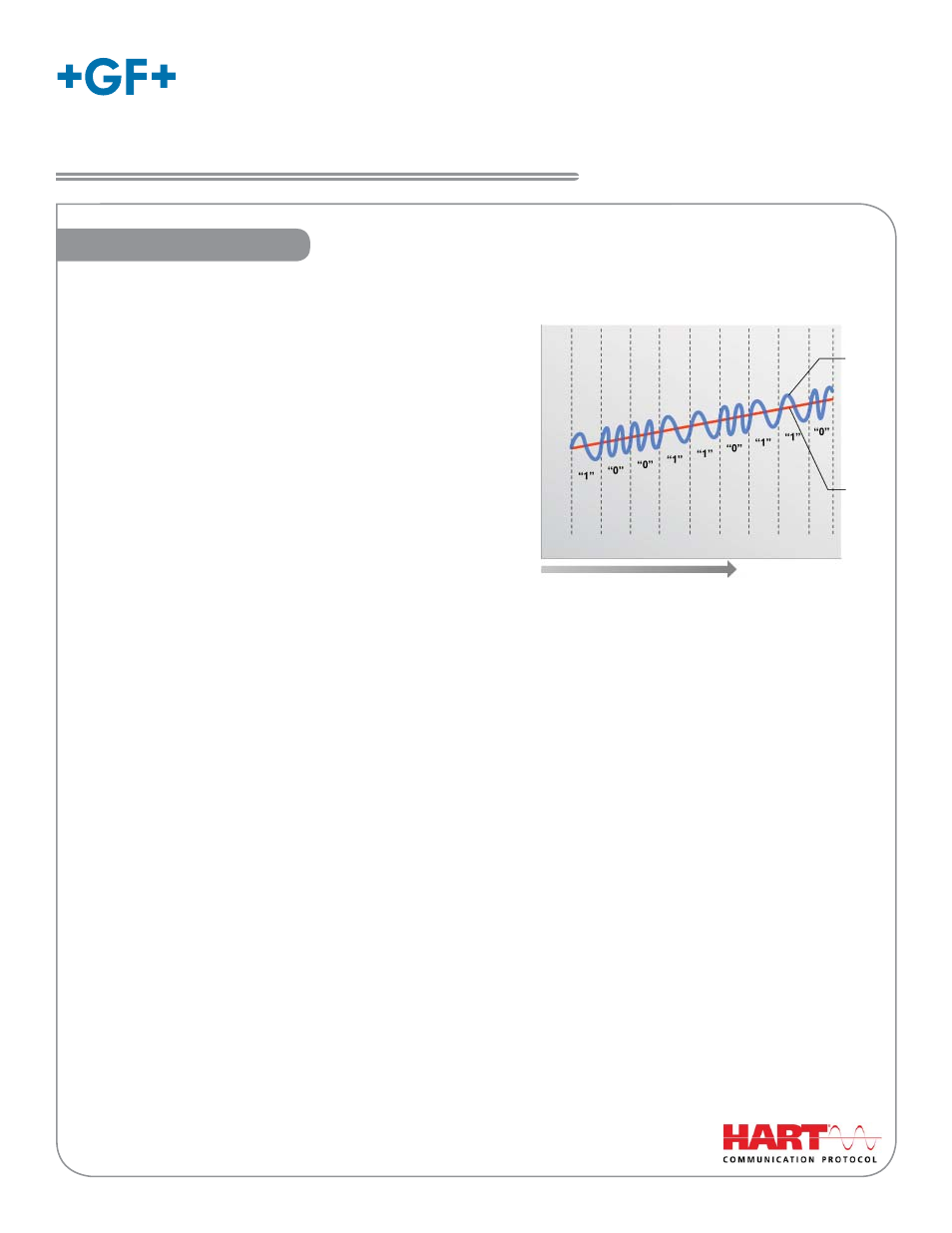

How HART

®

Works

The HART

®

(Highway Addressable Remote Transducer)

Protocol uses Frequency Shift Keying (FSK) to superimpose

digital signals on top of the analog 4 to 20 mA current loop.

This allows two-way digital communication to occur and

allows additional information beyond the normal process

data to be communicated to the 9900. This digital signal

can contain data such as device status, diagnostics, etc.

The HART protocol provides two simultaneous communication

channels: a 4 to 20 mA analog signal and a digital signal.

The analog signal communicates the primary measured

value using the 4 to 20 mA current loop.

Additional information is communicated using a digital

signal superimposed on the 4 to 20 mA signal.

Communication occurs between two HART-enabled devices,

in this application a Signet 9900 Transmitter and a PLC or

handheld device, using standard wiring and termination practices. The HART Protocol communicates at 1200 bits per sec-

ond without interfering with the 4 to 20 mA signal and allows the PLC or handheld device to communicate two or

more updates per second to and from the 9900.

Signet 9900 H COMM Module

3-9900.094 Rev. C 03/13 English

*3-9900.094*

English

Instruction Sheet

Introduction

20 mA -

4 mA -

Digital

Signal

Analog

Signal

Time

Note: Drawing not to scale

Frequency Shift Keying

Digital over Analog

Time

As deployed in the 9900 application, HART allows remote verifying, testing, adjusting and monitoring of primary and

secondary device variables. Features available in the 9900 Transmitter with H COMM Module installed:

• Adjust 4 mA: Allows fi ne-tuning to compensate for errors in other equipment connected to the 9900.

Adjust the minimum and maximum current output.

• Adjust 20 mA: Allows fi ne-tuning to compensate for errors in other equipment connected to the 9900.

Adjust the minimum and maximum current output.

• Supports Multi-Drop Mode: Allows up to four 9900 Transmitters be installed in Multidrop mode.

• Supports all Universal HART Protocol Revision 7.2 commands

• Supports many Common Practice Commands

• Makes Primary and Secondary values available at PLC. Secondary values are sensor-dependent and are

available with pH, Conductivity, Resistivity, Salinity and Level sensors.

The HART protocol operates according to the master-slave method. Any communication activity is initiated by the

master, usually a programmable logic controller (PLC) or a data acquisition system. HART accepts two masters: the

primary master - usually the control system (PLC) - and the secondary master - a PC laptop or handheld terminal

used in the fi eld.

HART fi eld devices - the slaves - never send without being requested to do so. They respond only when they have

received a command message from the master. Once a transaction (i.e., a data exchange between the control sta-

tion and the fi eld device) is complete, the master will pause for a fi xed time period before sending another command,

allowing the other master to break in. The two masters observe a fi xed time frame when taking turns communicating

with the slave devices.

HART

®

is a registered trademark of the HART Communication Foundation, Austin, Texas, USA.

Any use of the term HART hereafter in this document implies the registered trademark.