GF Signet 515 Rotor-X Paddlewheel Flow Sensor User Manual

Operating instructions, English, Description

*3-0515.090*

3-0515.090 Rev T 06/13

Signet 515/2536 Rotor-X Flow Sensors

English

Operating Instructions

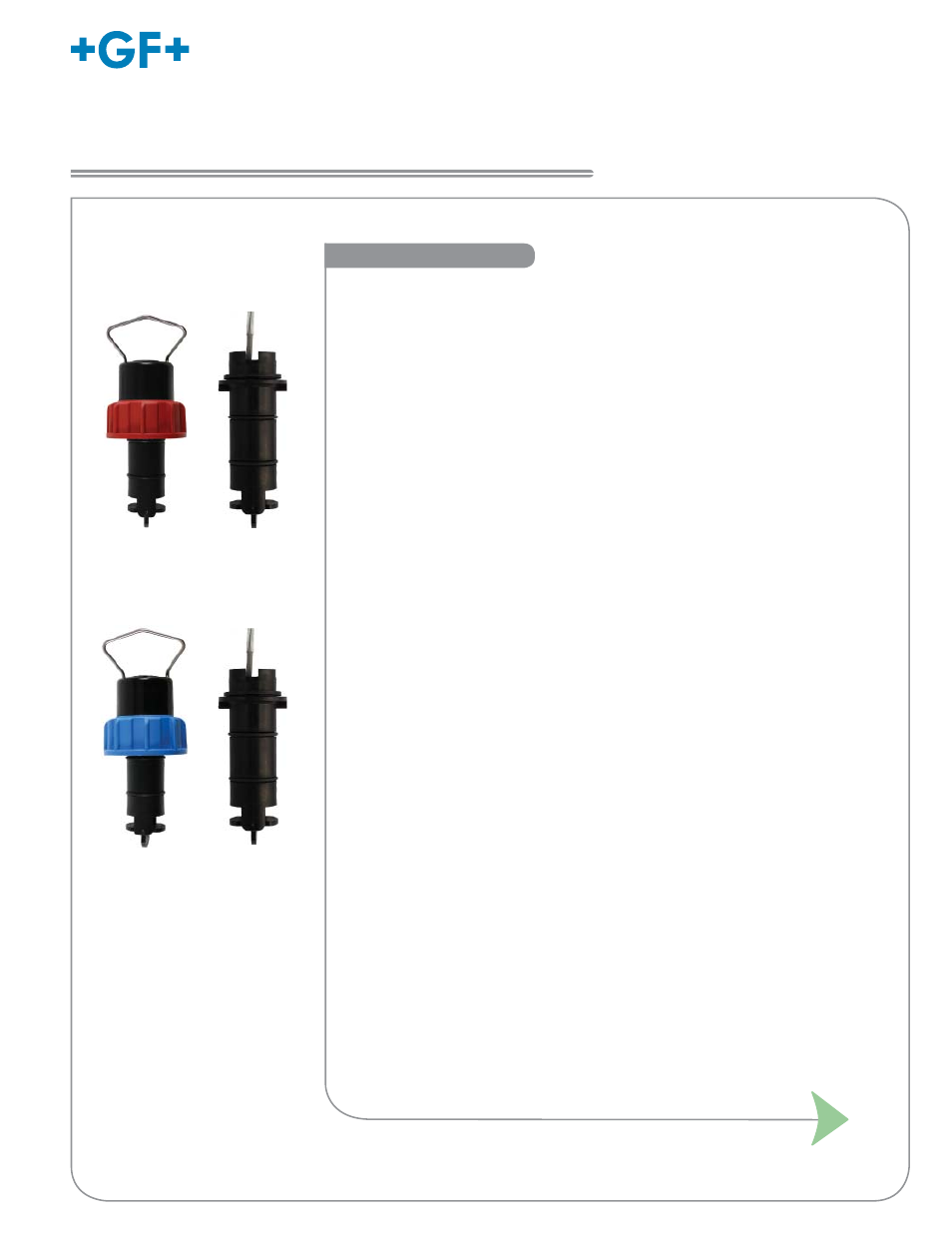

515 Sensor

(with red cap)

8510 Integral

Sensor

2536 Sensor

(with blue cap)

8512 Integral

Sensor

Description

Operating Instructions for all versions of 515/8510 and 2536/8512

Simple to install with time-honoured reliable performance, Signet 515 and 2536 Rotor-X

Paddlewheel Flow Sensors are highly repeatable, rugged sensors that offer exceptional

value with little or no maintenance.

Signet 515 and 2536 sensors measure liquid fl ow rates in full pipes and can be used in

low pressure systems.

•

The many material choices including PP and PVDF make this model highly versatile

and chemically compatible with many liquid process solutions.

•

Sensors can be installed in DN15 to DN900 (½ to 36 in.) pipes using Signet's

comprehensive line of custom fi ttings

• These

custom

fi ttings, which include tees, saddles, and weldolets, seat the sensor to

the proper insertion depth into the process fl ow.

•

The sensors are also offered in confi gurations for wet-tap installation requirements.

515/8510 Advantages:

•

Flow rate range 0.3 to 6 m/s (1 to 20 ft/s)

•

Installs into pipe sizes DN15 to DN900 (½ to 36 in.)

•

Wide Turndown Ratio of 20:1

•

Sinusoidal frequency output capable of driving a self-powered fl owmeter (Model 5090)

• Self-powered

•

Highly repeatable output

•

Chemically resistant materials

•

Easy to replace rotor

2536/8512 Advantages:

•

Flow rate range 0.1 to 6 m/s (0.3 to 20 ft/s)

•

Installs into pipe sizes DN15 to DN900 (½ to 36 in.)

•

Wide Turndown Ratio of 66:1

• Open-collector

output

•

High resolution and noise immunity

•

Chemically resistant materials

•

Easy to replace rotor