GF Signet 2450 Pressure Sensor User Manual

Signet 2450 pressure sensor, Description 2. specifi cations, English

Safety Instructions

1. Prior to installation or removal:

• Depressurize and vent system

• Drain below sensor level

2. Confi rm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifi cations.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

6. Dispose of properly; DO NOT INCINERATE!

Signet 2450 Pressure Sensor

1. Description

2. Specifi cations

General

Compatibility

Digital (S

3

L) models:

8450, 8900, 9900

4 to 20 mA models:

PLC

Wetted materials:

• Sensor housing:

PVDF

• Diaphragm:

Ceramic

• Seal:

FPM

Process connection:

• -3X, -7X:

1

/

2

in. Union male thread,

where X = U, L, or H

Rear connection:

3

/

4

in. NPT male thread

Cable type:

3 cond + shield, 22 AWG

Standard cable length:

• -3X, -7X:

4.6 m (15 ft)

Sensor Accuracy:

±1% of full scale @ 25 °C

Thermal sensitivity shift: ±0.03% of full scale per °C

Shipping weight:

0.3 kg (0.65 lb.)

Electrical

Power Requirements:

• Digital (S

3

L) models:

5 to 6.5 VDC ±10%, <1.5 mA

• 4 to 20 mA models:

12 to 24 VDC ±10% regulated

Short circuit & reverse polarity protected

Digital (S

3

L) output:

• Type:

Serial ASCII, TTL level 9600 bps

• Accuracy:

±1% of full scale @ 25 °C

• Repeatability:

±0.5% of full scale

• Resolution:

0.01 psi (0.001 psi for -XU)

• Update rate:

<100 ms

4 to 20 mA output:

• Accuracy:

±32

μA

• Repeatability:

±0.5% of full scale

• Resolution:

<5 μA

• Span:

Field-scaleable

(see section 6.3 for factory settings)

• Max loop impedance:

100 Ω @ 12 V

325

Ω @ 18 V

600

Ω @ 24 V

• Update rate:

<100 ms

• Operating range (Max. pressure for accuracy specifi cations):

-XU 0 to 0.7 bar (0 to 10 psig)

-XL 0 to 3.4 bar (0 to 50 psig)

-XH 0 to 17.2 bar (0 to 250 psig)

Table of Contents

1. Description

2. Specifi cations

3. Installation

4. Digital (S

3

L) Wiring

5. 4 to 20 mA Wiring

6. 4 to 20 mA Span

Adjustment

7. Ordering Information

The 2450 Pressure Sensor has a one-piece injection molded PVDF body and ceramic diaphragm for superior compatibility in corrosive

liquids. These sensors are available with Digital (S

3

L) digital output or fi eld-scaleable 4 to 20 mA output. Select from three (3) pressure

ranges for optimal measurement resolution. Built-in temperature compensation provides outstanding accuracy over a wide operating

range. Versions with

1

/

2

in. union process connection are best suited for in-line installations.

Integral adapters (sold separately) may be used to create a compact assembly with fi eld mount versions of the 8450 Pressure Transmitter

and the 9900 Transmitter.

3-2450.090-1 Rev. K 05/13 English

*3-2450.090-1*

English

• Vacuum range:

-XU -0.1 to 0.7 bar

(-1.5 to 10 psi)

-XL -0.41 to 3.4 bar

(-6 to 50 psi)

-XH -0.96 to 17.2 bar

(-14.6 to 250 psi)

• Proof pressure

(Max. pressure without damage):

-XU 1.4 bar (20 psig)

-XL 5.2 bar (75 psig)

-XH 20.7 bar (300 psig)

Environmental

• Relative humidity:

0 to 95% (Non-condensing)

• Storage temperature:

-20 °C to 100 °C (-4 °F to 212 °F)

• Operating temperature: -15 °C to 85 °C (5 °F to 185 °F)

Standards and Approvals

• CE

• RoHS Compliant

• Manufactured under ISO 9001 for Quality,

ISO 14001 for Environmental Management and

OHSAS 18001 for Occupational Health and Safety.

Declaration of Conformity according to FCC Part 15:

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received,

including interference that may cause undesired operation.

China RoHS (Go to www.gfsignet.com for details)

0

-40

-20

0

20

40

60

80

100

120

°F

°C

-40

-4

32

68

104

140

176

212

248

(bar)

(psi)

1.7

3.4

5.2

6.9

8.6

10.3

25

50

75

100

125

150

12.1

175

13.8

200

225 15.5

275 19.0

-XH

-XL

-XU

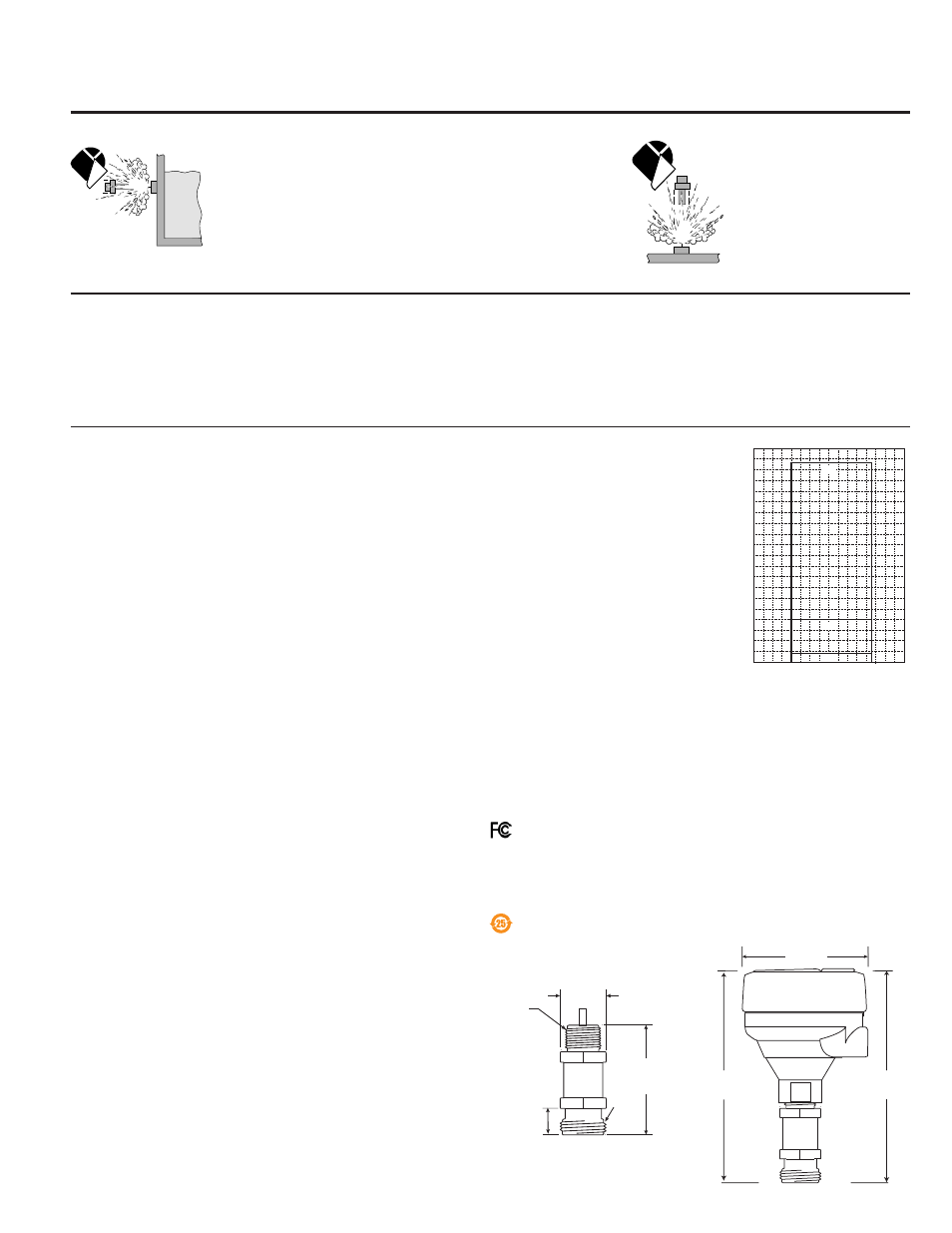

Dimensions

3-2450-3X, -7X

34 mm

(1.34 in.)

¾ in.

NPT

81 mm

(3.18 in.)

½ in.

Male

Union

19.1 mm

(0.75 in.)

3-8450, 3-9900-1

97 mm (7.75 in.)

(8450)

96 mm

(3.78 in.)

216.1 mm (8.5 in.)

(9900-1)

USE THE ATTACHED ADHESIVE LABEL TO PRESERVE THE SAFETY INSTRUCTIONS!