GF Signet 2551 Magmeter Flow Sensor - Display User Manual

Signet 2551 display magmeter, Warning

Signet 2551 Display Magmeter

SAFETY INSTRUCTIONS

1. Depressurize and vent system prior to installation or removal.

2. Con¿ rm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure speci¿ cations.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

*3-2551.090-1*

3-2551.090-1

Rev. K 10/12

English

1. Description

The 2551 Magmeter measures the À ow rate in a full pipe by monitoring the voltage produced when the (conductive) À uid moves through

a magnetic ¿ eld. Output options include a traditional frequency signal, a serial data (Digital (S

3

L)) output, and a 4 to 20 mA output.

The 2551 Magmeter is available in three sizes that will accommodate pipes from ½-inch through 36-inch diameters.

Select from three different material combinations to match the Magmeter to the application requirements.

English

1.

Description

1

2. Specifi

cations

2

3. Installation: Pipe fi

ttings

3

3.1 Installation: Selecting a Location

3

4. Overview of 2551 Display versions

4

5.

Wiring

5

5.1

Basic

Wiring

5

5.2 Wiring: Mirror Relay 1 output

5

5.3 2551 and other manufacturer's instruments

5

5.4 Wiring to Signet Flow Instruments

6

5.5

Wiring

Relays

7

6.

View

Menu 8

6.1 Resetting the Resetable Totalizer

8

6.2

Navigating

the

Menus

9

6.3

Keypad

Functions

9

6.4

Security

Code

9

7. Setup

Menu

10

7.1 Averaging and Sensitivity

11

7.2 Bi-Directional Flow

12

7.3 Calibration Data

12

8. Calibration

Menu

14

8.1 Volume method of calibration

14

8.2 Rate method of calibration

14

9. Relay

Menus

15

9.1 Pulse Relay mode

15

9.2 Total Relay mode

15

9.3 High, Low, or Window Relay modes

16

10. Test Menu

17

11. Options Menu

17

11.1 Output Modes

17

12. Technical Information

18

12.1 Grounding

18

12.2 Maintenance

19

12.3 Troubleshooting

19

13. Ordering Information

20

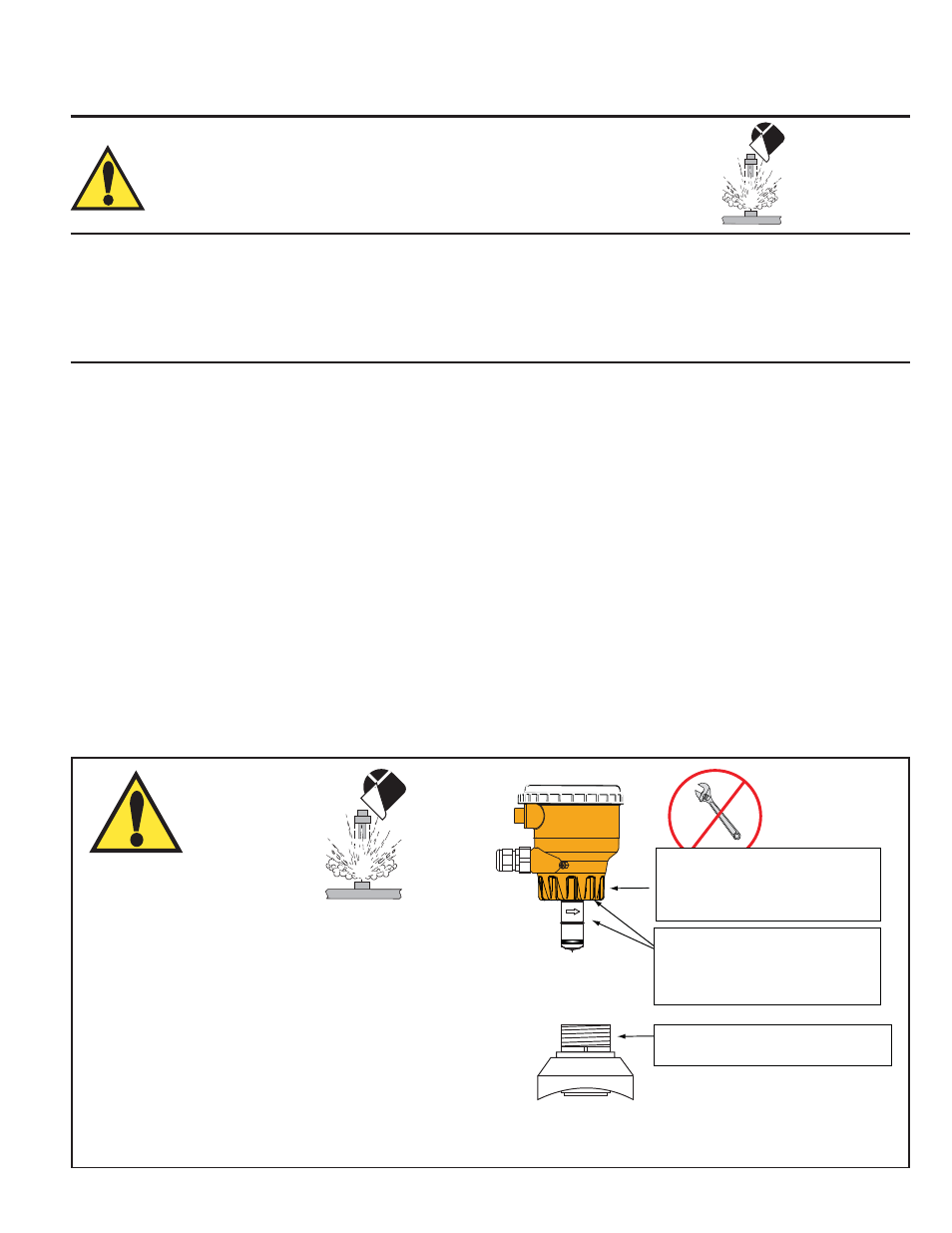

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT

IN THE SENSOR BEING EJECTED FROM THE PIPE!

• DO NOT USE ANY TOOLS ON THE RETAINING CAP.

HAND TIGHTEN ONLY.

• LUBRICATE O-RINGS WITH A NON-PETROLEUM BASED,

VISCOUS LUBRICANT (GREASE) COMPATIBLE WITH

THE SYSTEM.

• DO NOT USE THREAD SEALANT OR LUBRICANTS ON

THE RETAINING CAP OR ON THE PLASTIC FITTING

THREADS.

• IF LEAKING IS OBSERVED FROM THE RETAINING CAP,

IT INDICATES DEFECTIVE OR WORN O-RINGS ON THE

SENSOR. DO NOT ATTEMPT TO CORRECT BY FURTHER TIGHTENING.

DO NOT USE thread sealant

or lubricants on the fitting threads!

Do not use any tools to

tighten the yellow retaining cap.

DO NOT USE thread sealant or

lubricants on retaining cap!

Lubricate O-rings with a

non-petroleum based, viscous

lubricant (grease) compatible

with the system.

Contents

WARNING!