Burkert Type 8611 User Manual

Page 78

78

FunctionsoftheConfigurationLevel

setting aid:

An unsatisfactory dynamic of the control is improved by increasing the proportional gain [K

p

]. The fol-

lowing must be observed:

In the event of impermissibly high overshoots after set-point value jumps or in the event of an unstable

control, the proportional gain [K

p

] should be reduced.

12.13.3.

TREG – setting the controller cycle time

This parameter is only available if quasi-continuous actuating parameters have been selected

(

MODE = PCV, 2P – T or 3P – T).

TREG defines the cycle time in seconds in that a set-point/actual value comparison is regularly executed and a new

manipulated variable is calculated. Within this time the pilot valve will be switched one time.

The parameter

TREG has to be set in that way to get an acceptable life time of the valve on the one side and to

avoid an tolerable oscillation of the process value on the other side.

The parameter

TREG should be smaller than the reset time [T

n

]

12.13.4.

TN – setting reset time

With this parameter the I-portion of continuous or quasi-continuous control loops can be set.

The reset time [T

n

] in seconds is the time that is required to obtain an equally large change in the manipulated

variable by the I portion, as occurs due to the P portion.

The time it takes for getting about 60 - 70 % of the process value change can be taken as an start value for T

n

.

T

n

can be selected between 0.01 and 999.9 s. When 999.9 is set, the I-portion is deactivated (independent from

decimal place).

12.13.5.

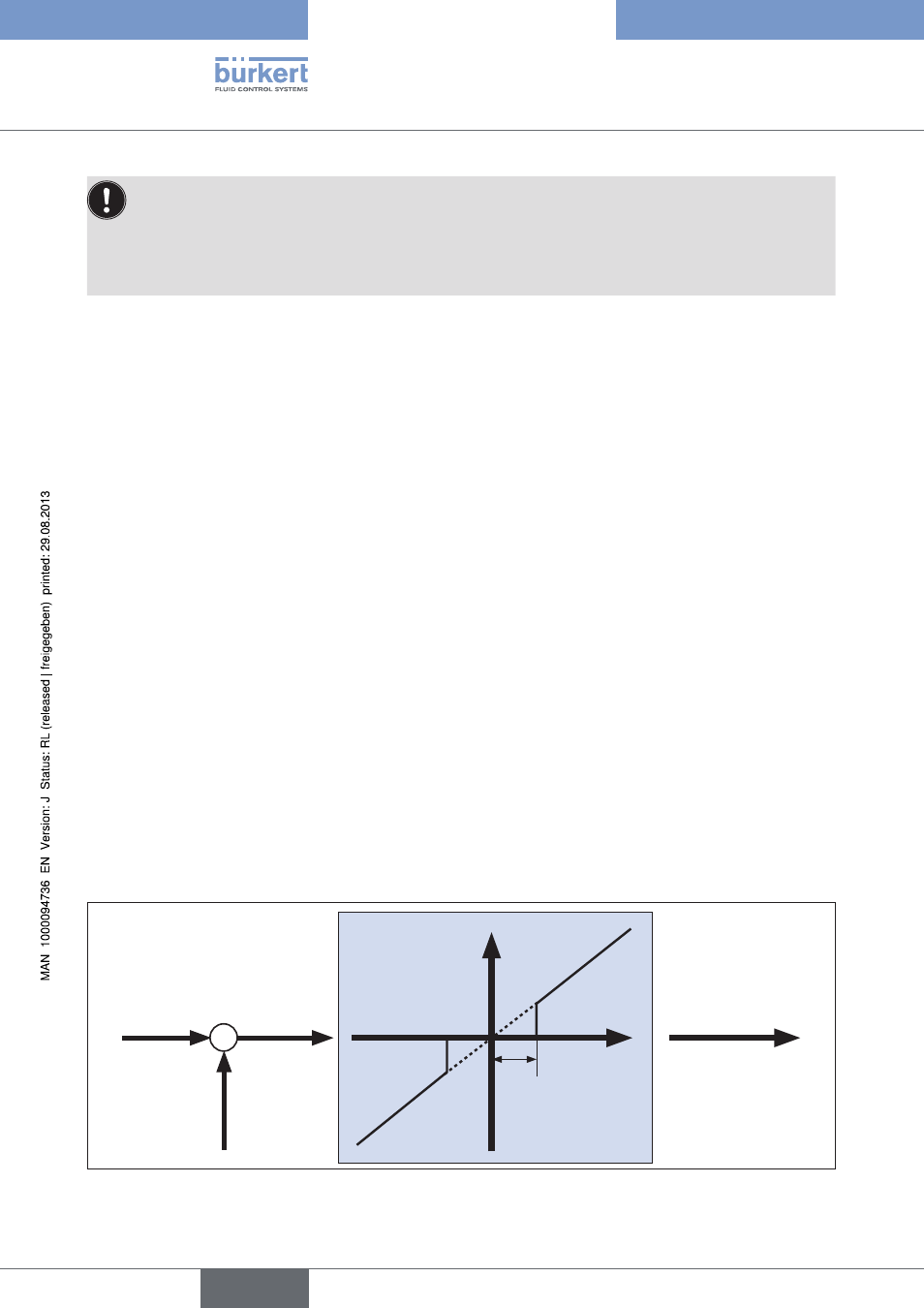

DEAD – insensitivity range (dead zone)

This function causes the process controller to respond only from a specific control difference. This protects the

control valves.

The dead zone is entered as an absolute value according to the unit selected in the

UNIT menu.

x‘

x

x‘

to the controller

Set-point

value (SP)

Control

difference

Process

value

–

dead

zone

+

Figure 55:

DEAD; Insensitivity range (dead zone)

english

Type 8611