Part 2 - transducer & rtd installation, Z-mount transducer installation – Dynasonics TFXP Series Transit Time Ultrasonic Flow Meter User Manual

Page 31

Rev. 5/09

- 2.13 -

TFXP

2. On horizontal pipes, mount the transducer in an orientation so

that the cable exits at ±45° from the side of the pipe. Do not

mount with the cable exiting on either the top or bottom of the

pipe. On vertical pipes the orientation is not critical. See Figure

2.2 on page 2.8.

3. Tighten the wing nuts or “U” bolts so that the grease begins to

flow out from the edges of the transducer and from the gap

between the transducer halves. Do not over tighten.

4. If signal strength is less than 5 percent, remount the transducer

at another location on the piping system.

5. If signal strength is greater than 195 percent, contact

Dynasonics for adjustments to the AGC (Automatic Gain)

settings.

Mounting Transducers in Z-Mount Configuration

Installation on larger pipes requires careful measurements of the

linear and radial placement of the DTTN and DTTH transducers.

Failure to properly orient and place the transducers on the pipe may

lead to weak signal strength and/or inaccurate readings. This

section details a method for properly locating the transducers on larger

pipes. This method requires a roll of paper such as freezer paper or

wrapping paper, masking tape and a marking device.

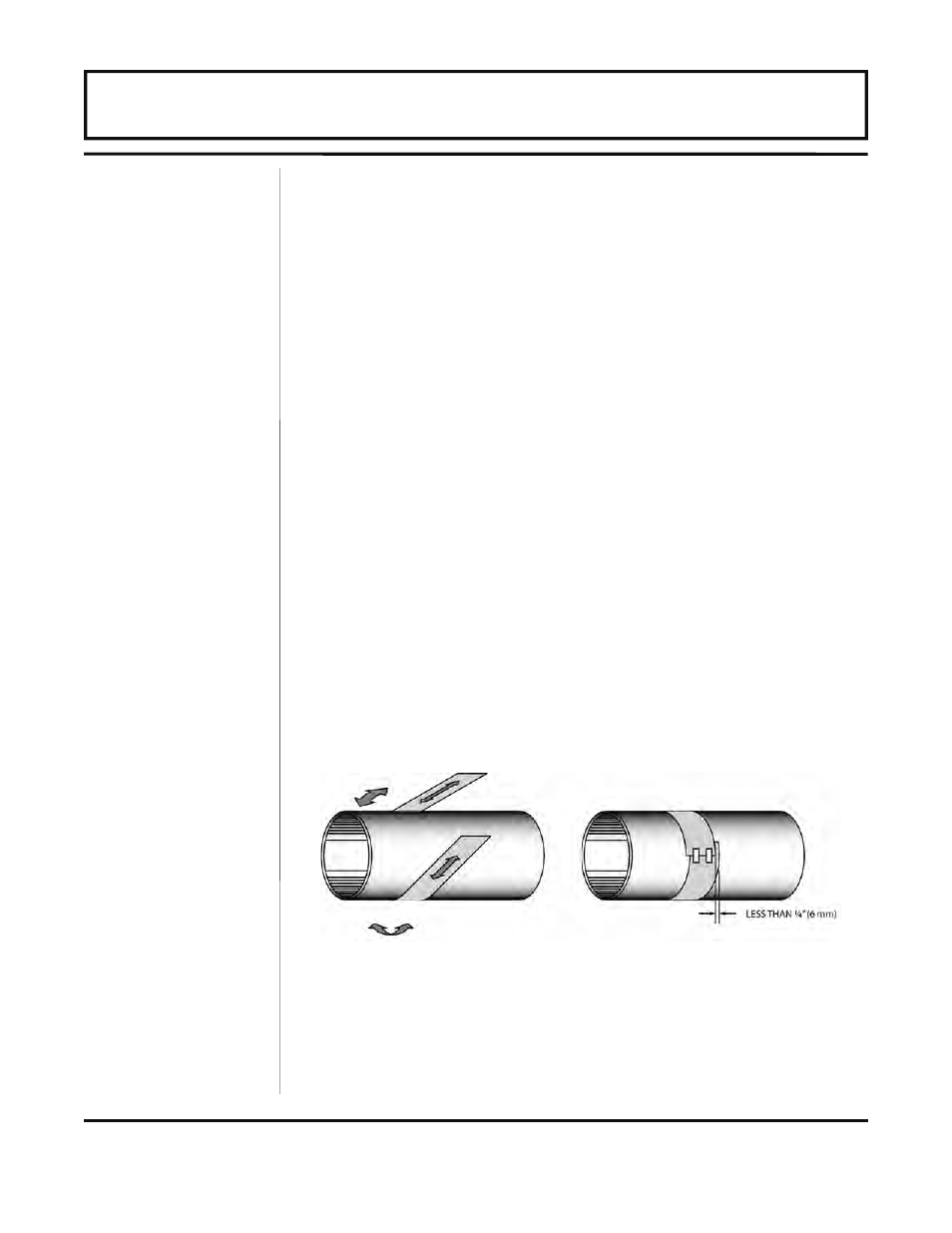

1. Wrap the paper around the pipe in the manner shown in Figure

2.9. Align the paper ends to within 1/4 inch (6 mm).

2. Mark the intersection of the two ends of the paper to indicate the

circumference. Remove the template and spread it out on a flat

surface. Fold the template in half, bisecting the circumference.

See Figure 2.10 on page 2.14.

Z-Mount

Transducer

Installation

Figure 2.9 — Paper Template Alignment

PART 2 - TRANSDUCER & RTD INSTALLATION