Part 2 - transducer & rtd installation, Transducer mounting, Pipe preparation – Dynasonics TFXP Series Transit Time Ultrasonic Flow Meter User Manual

Page 26

Rev. 5/09

- 2.8 -

TFXP

After selecting an optimal mounting location (Step 1) and

successfully determining the proper transducer spacing (Step 2) the

transducers may now be mounted onto the pipe.

Before the transducers are mounted onto the pipe surface, an area

slightly larger than the flat surface of each transducer must be

cleaned of all rust, scale and moisture. For pipes with rough

surfaces, such as ductile iron pipe, it is recommended that the pipe

surface be ground flat. Paint and other coatings, if not flaked or

bubbled, need not be removed. Plastic pipes typically do not

require surface preparation other than soap and water cleaning.

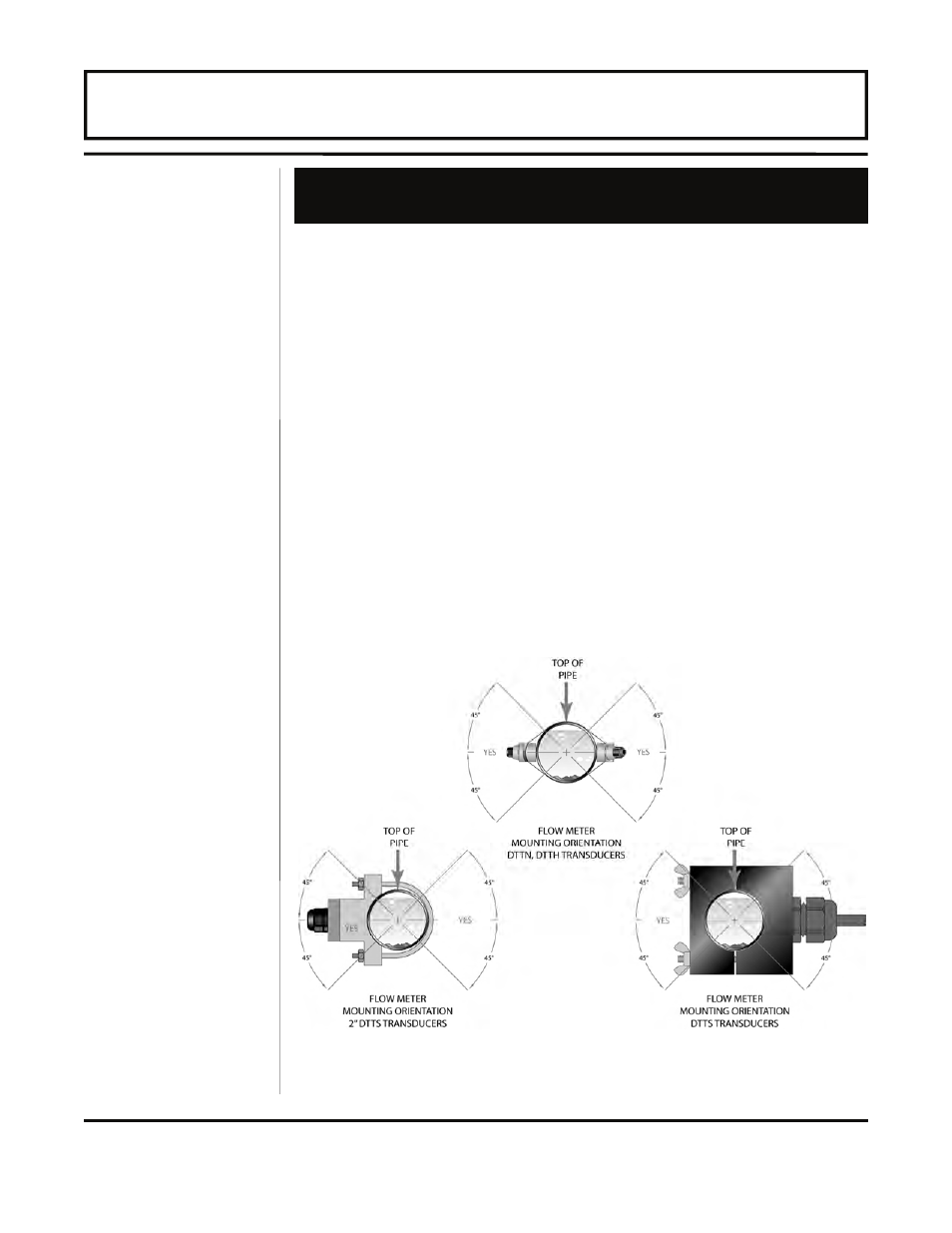

The DTTN and DTTH transducers must be properly oriented and

spaced on the pipe to provide optimum reliability and performance.

On horizontal pipes, when Z-Mount is required, the transducers

should be mounted 180 radial degrees from one another and at

least 45 degrees from the top-dead-center and bottom-dead-center

of the pipe. See Figure 2.2. Also see Z-Mount Transducer

Installation on page 2.13. On vertical pipes the orientation is not

critical.

3. Transducer Mounting

Pipe

Preparation

Figure 2.2 — Transducer Orientation - Horizontal Pipes

PART 2 - TRANSDUCER & RTD INSTALLATION