Part 2 - transducer & rtd installation – Dynasonics TFXP Series Transit Time Ultrasonic Flow Meter User Manual

Page 30

Rev. 5/09

- 2.12 -

TFXP

DTTH High Temperature Transducers

Mounting of high temperature transducers is similar to standard

DTTN transducers. High temperature installations require acoustic

couplant that is rated not to “flow” at the temperature that will be

present on the pipe surface.

Installation consists of the following steps:

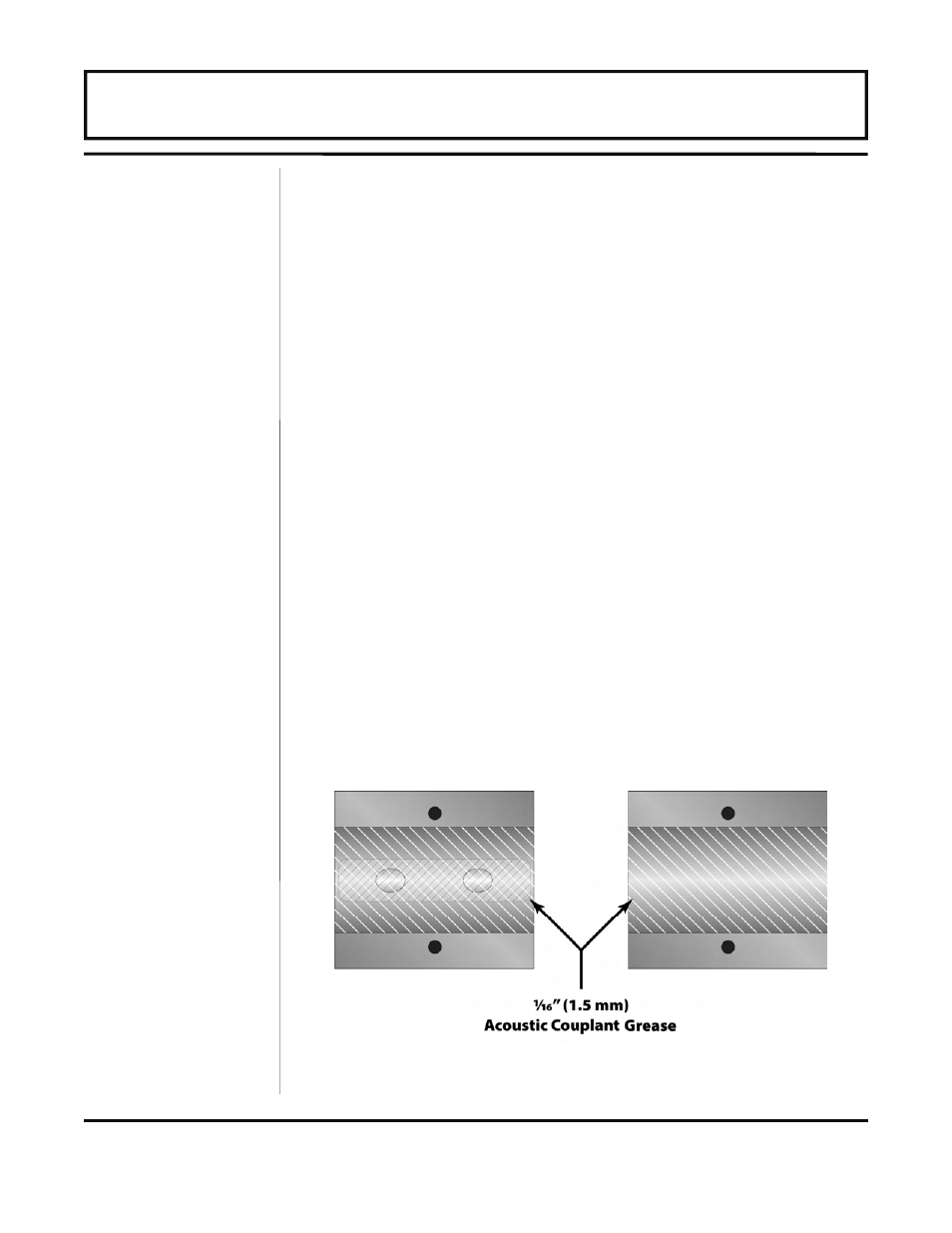

1. Apply a thin coating of high temperature acoustic couplant to the

entire surface of the transducer face. The thickness of the

application should be approximately 1/16 inch (1.5 mm).

2. Install the two transducers following the procedures detailed in

the DTTN instructions on page 2.9 of this manual.

DTTS/DTTC Small Pipe Transducer Installation

The small pipe transducers are designed for specific pipe outside

diameters. Do not attempt to mount a DTTS or DTTC transducer

onto a pipe that is either too large or too small for the transducer.

Contact the Dynasonics factory to arrange for a replacement

transducer that is the correct size.

DTTS and DTTC installations consist of the following steps:

1. Apply a thin coating of silicone grease to both halves of the

transducer housing where the housing will contact the pipe. See

Figure 2.8.

Figure 2.8 — Application of Grease

DTTS and DTTC Transducers

DTTH

Transducers

for High

Temperature

DTTS/DTTC

Small Pipe

Transducer

Installation

PART 2 - TRANSDUCER & RTD INSTALLATION