1 introduction, 2 physical modbus rs485 network wiring connections, 1 bms slave to ems master wiring connections – AERCO Modbus Communications Manual User Manual

Page 57: Modbus, Communication, Gf-114

Chapter 4

MODBUS

Communication

GF-114

Hardware Setup & Installation

USER MANUAL

OMM-0035_0C

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288

Page

57 of 200

CHAPTER 4. MODBUS NETWORK HARDWARE SETUP

& INSTALLATION

4.1 INTRODUCTION

This Section provides basic information on planning and setup of a Modbus Communication

Network utilizing AERCO C-More Boiler Controllers and Boiler Management Systems (BMS/

BMS II) and AERCO Control System (ACS). It also provides basic information on Modbus

Network setup utilizing AERCO BMS/ BMS II/ACS or C-More Slaves with a Master EMS (or

BAS) provided by other manufacturers.

4.2 PHYSICAL MODBUS RS485 NETWORK WIRING CONNECTIONS

To properly perform combustion calibration, the proper instruments and tools must be used and

correctly attached to the unit. The following paragraphs outline the necessary tools and

instrumentation as well as their installation.

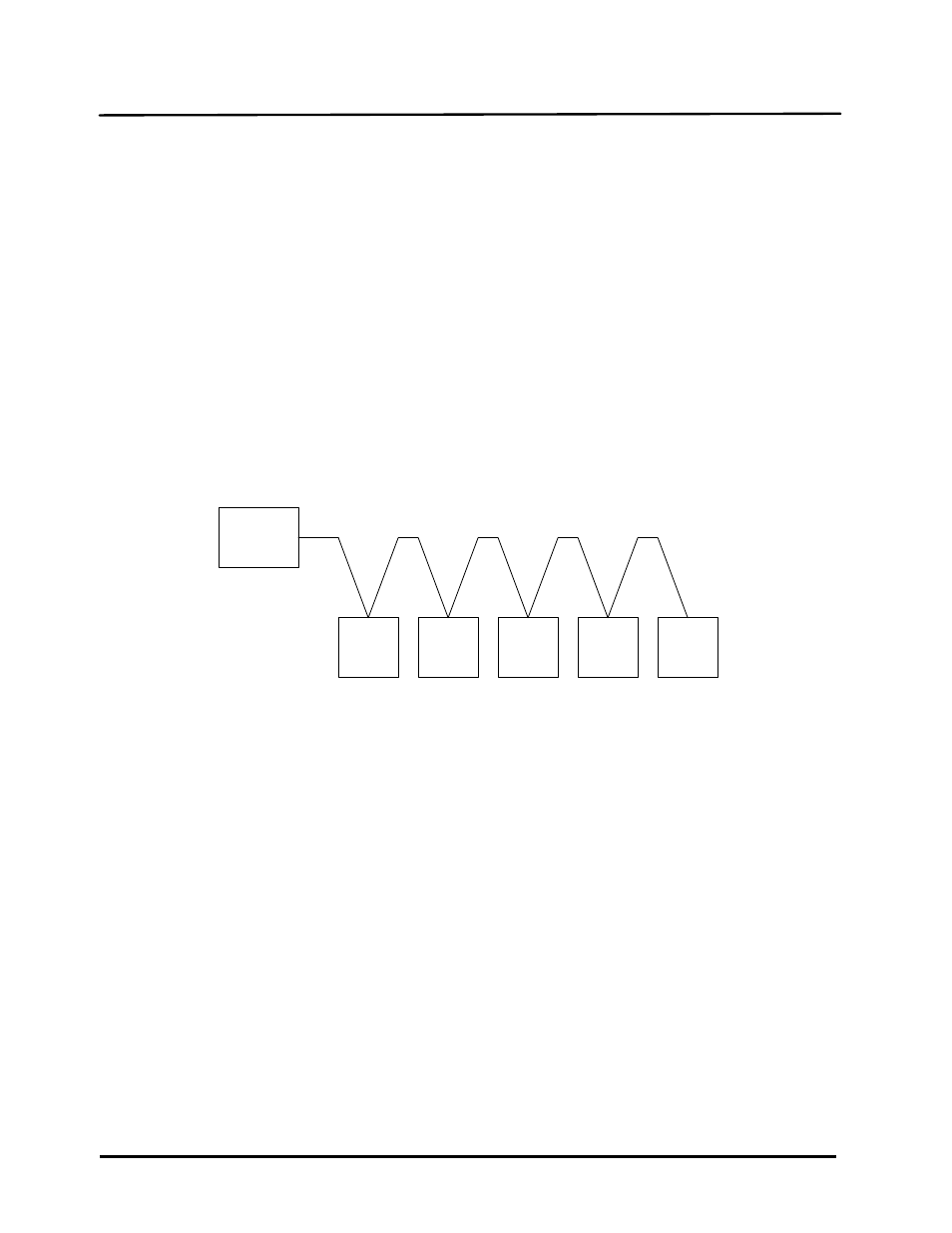

MASTER

SLAVE

#1

SLAVE

#2

SLAVE

#3

SLAVE

#4

SLAVE

#5

Figure 4-1: Typical Daisy-Chain Modbus/RS485 Network

The physical wiring connections for a Modbus Network utilizing an AERCO BMS/BMS II/ACS

and C-More Boiler Controllers should be made using shielded twisted-pair wire, from 18 to 24

AWG. Examples of suitable wire are: Belden #9841, #8761, #3105A, or equivalent.

The actual locations of the wiring connectors necessary for Modbus Network implementation

utilizing the AERCO BMS, BMS II, or ACS and C-More Boiler Controllers are provided in

paragraphs 4.2.1 and 4.2.2 respectively. Where necessary, connector pin-out information is also

provided.

4.2.1 BMS Slave To EMS Master Wiring Connections

Wiring connections between an EMS Master and an AERCO BMS Slave can be made at either

the RS232 (DB9) port on the left side of the BMS, or at the internal RS232 connector located on

the terminal board behind the connection cover on the BMS. These connections are shown in

Figure 4-2. The internal RS232 connections are used when interfacing with an EMS Master via

a conduit connection at the bottom edge of the BMS enclosure. If the internal RS232

connections are used, it is recommended that nothing be connected to the external RS232 (DB9)

port.

If the EMS Master being used contains only an RS485 port (2-wire or 4-wire), an RS485-to-

RS232 Converter is required. A BMS option is available with a built-in RS485-to-RS232

Converter to permit a conduit connection between the EMS and BMS. If the external RS232 port

on the left side of the BMS is used, a separate external converter is required.