Cub Cadet ISeries User Manual

Page 137

ELECTRICAL SYSTEM

131

2.

Importance of battery charge level and condi-

tion: A fully charged battery that is in good condi-

tion is an important factor when trying to

diagnose other parts of an electrical system:

•

Some charging systems do not work if the sys-

tem voltage falls below 6V. It takes a certain

amount of voltage to excite the fields in the alter-

nator.

•

Some solid-state components will not work if the

system voltage falls below a given threshold.

•

Some solid-state components can be damaged

by the jump-starting that accompanies operation

with a dead battery.

•

Many electric PTO clutches will fail to work

dependably if battery needs to be replaced.

Even though the charging system produces

enough out-put to drive the clutch, it is over-

taxed driving the clutch and forcing a charge into

a damaged battery.

•

Continued operation with a weak battery over-

taxes the charging system.

3.

Charging the battery:

NOTE: It is best to remove batteries from equip-

ment for charging to minimize corrosion from

out-gassing during charging.

CAUTION: When disconnecting or removing the

battery, disconnect the ground cable first. When

reconnecting or installing a battery, connect the

ground cable last. These steps will minimize the

chance of shorting-out the battery posts with a

tool.

3a. Batteries on most modern outdoor power

equipment are 12 volts so set the charger to

12 volts.

3b. Set the charge rate to 2 amps.

3c. Charge the battery until it is fully charged.

Most battery chargers have an amp gauge

to show the charging rate. When the gauge

is at zero, stop charging the battery.

! CAUTION

! CAUTION

Never charge an outdoor power

equipment battery at a rate higher

than 2 amps. Damage to the battery

will result.

! CAUTION

! CAUTION

Never attempt to charge or jump a

frozen battery.

4.

Checking battery condition: There are three

things to do when testing a battery:

•

Visual inspection

•

Electrolyte test

•

Operational test

4a. Visual inspection

•

Inspect the battery and battery connections for

corrosion. Clean if necessary. Neutralize acid

with baking soda, and protect the terminals once

they are cleaned.

NOTE: Battery cable corrosion is the most com-

mon type of increased resistance circuit failures.

•

Inspect the battery case for signs of damage and

missing vent caps. Battery cases that bow out in

the middle indicate that the battery froze or over

heated and should be replaced.

5.

Check the electrolyte level if the caps can be

removed. Fill as needed with distilled water.

After initial charging, do not add electrolyte to

the battery.

6.

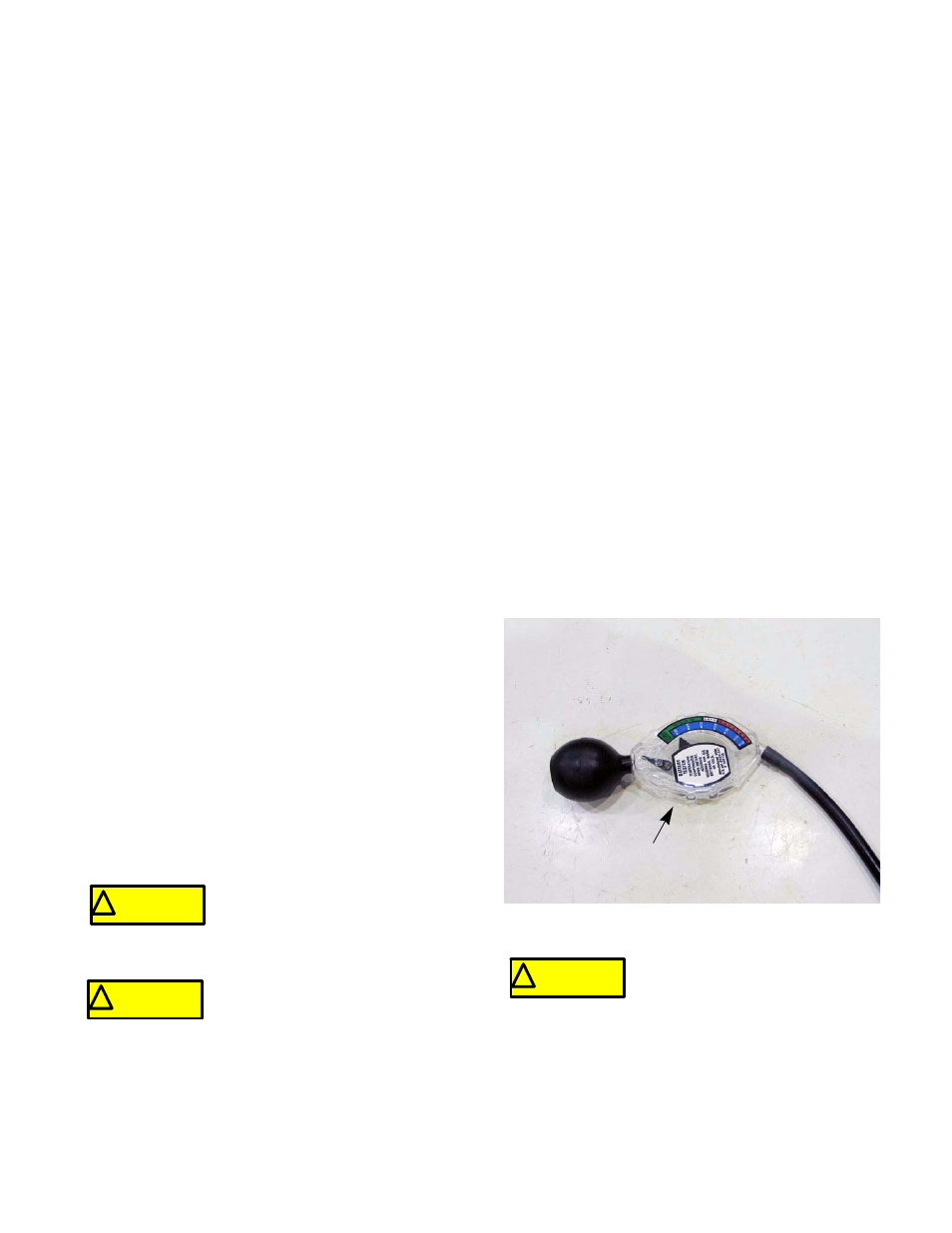

Hydrometer test (non-sealed batteries only)

See Figure 7.33.

6a. Give the battery at least ten minutes for the

electrolyte to stabilize after charging the bat-

tery or adding water to the cells.

6b. Measure the temperature of the electrolyte

in the middle cells of the battery.

Figure 7.33

Hydrometer

! CAUTION

! CAUTION

Always wear eye protection and

acid resistant gloves when working

with electrolyte. Use baking soda to

neutralize any spilled acid.