Rockwell Automation 2198-Hxxx Kinetix 5500 Servo Drives User Manual User Manual

Page 143

Rockwell Automation Publication 2198-UM001D-EN-P - May 2014

143

Troubleshooting the Kinetix 5500 Drive System

Chapter 7

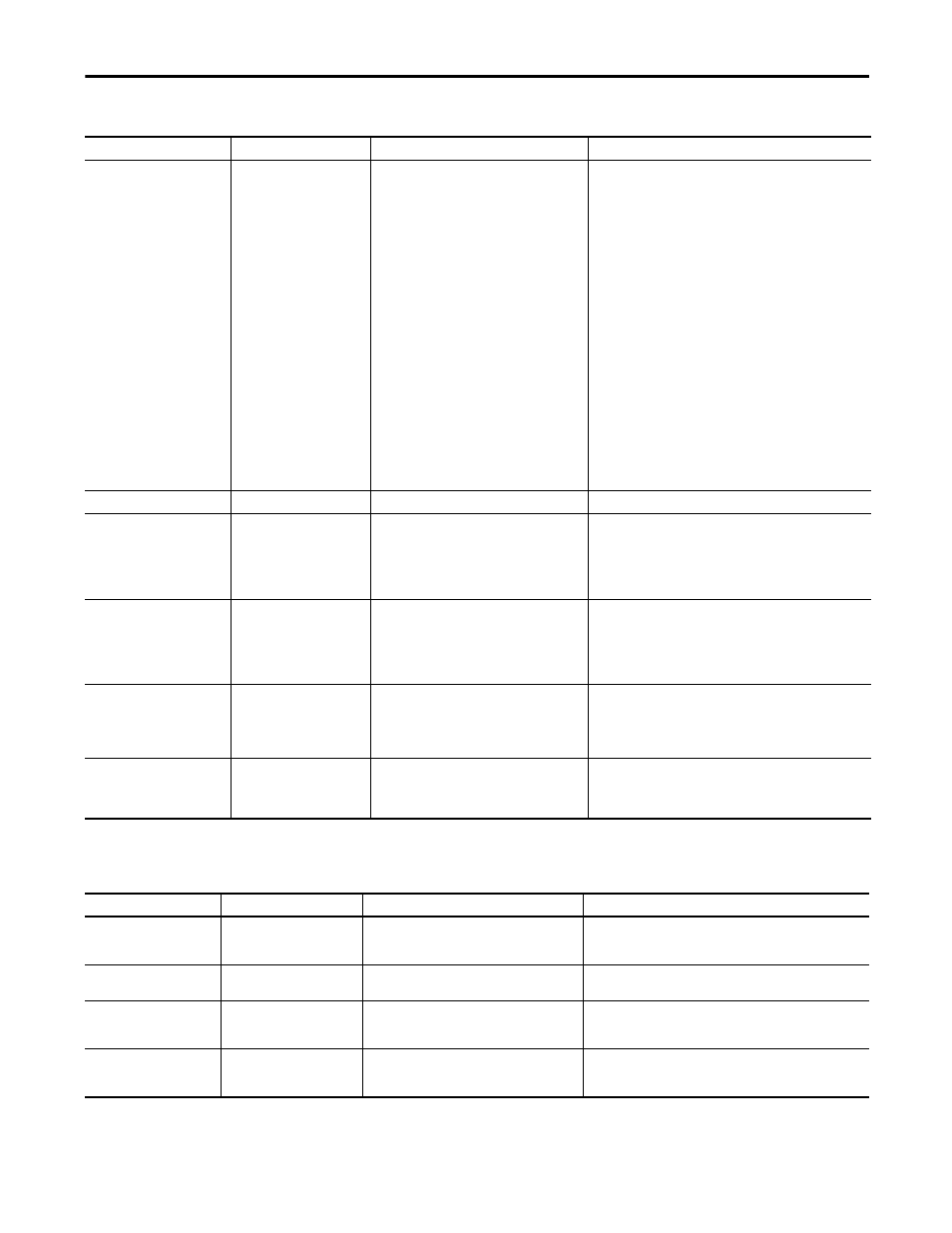

FLT S47 – FDBK DEVICE FAILURE nn

Feedback Device Failure

The feedback device has detected an internal error.

The nn sub-code is defined as follows:

1:

ACCELERATION OVERFLOW

4:

TRACKING FILTER ERROR

5:

VECTOR LENGTH ERROR

6:

COUNTER ERROR

7:

SYNCHRONIZATION ERROR

16: SINGLE TURN ERROR

17: MULTI TURN AMPLITUDE ERROR

18: MULTI TURN SYNC ERROR

19: MULTI TURN VECTOR LENGTH ERROR

35: STANDARD PARAMETER ERROR

36: INTERNAL COMMUNICATION ERROR1

37: INTERNAL COMMUNICATION ERROR2

38: INTERNAL SYSTEM ERROR

48: CRITICAL TEMPERATURE

49 : CRITICAL LED CURRENT

50: CRITICAL SUPPLY VOLTAGE

51: CRITICAL SPEED

52: CRITICAL ACCELERATION

53: COUNTER OVERFLOW

54: INTERNAL MONITORING ERROR

66: INTERNAL RESOURCE ACCESS ERROR

• Check motor feedback cable and connector

• Cycle control power

• Replace motor if fault continues

• Check feedback shield connection

• Reduce shock and vibration to motor

FLT S49 – BRAKE SLIP FLT

Brake Slip Exception

Motor slip has exceeded brake slip tolerance.

Check motor brake.

FLT S54 – POSN ERROR

Excessive Position Error Fault

The position error of the position control loop has

exceeded the value given by Position Error Tolerance

for a time period given by Position Error Tolerance

Time.

• Check position loop tuning

• Increase the feedforward gain

• Verify sizing of the drive and motor

• Check motor power wiring

• Increase Position Error Tolerance and/or Position Error Tolerance

Time attribute values

FLT S55 – VEL ERROR

Excessive Velocity Error Fault

The velocity error of the velocity control loop has

exceeded the value given by Velocity Error Tolerance

for a time period given by Velocity Error Tolerance

Time.

• Check velocity loop tuning

• Reduce acceleration

• Verify sizing of the drive and motor

• Check motor power wiring

• Increase Velocity Error Tolerance and/or Velocity Error Tolerance

Time attribute values

FLT S56 – OVERTORQUE LIMIT

Overtorque Limit Fault

Motor torque has risen above user defined maximum

torque level given by Overtorque Limit for a time

period given by Overtorque Limit Time.

• Verify Torque Trim value

• Verify motion profile

• Verify sizing of the drive and motor

• Increase Overtorque Limit and/or Overtorque Limit Time attribute

values

FLT S57 – UNDERTORQUE LIMIT

Undertorque Limit Fault

Motor torque has dropped below user defined

minimum torque level given by Undertorque Limit for

a time period given by Undertorque Limit Time.

• Verify motion profile

• Verify sizing of the drive and motor

• Decrease Undertorque Limit and/or Undertorque Limit Time

attribute values

Table 56 - FLT Sxx Fault Codes (continued)

Exception Code on Display

Exception Text

Problem

Possible Solutions

Table 57 - FLT Mxx Fault Codes

Exception Code on Display

Exception Text

Problem

Possible Solutions

FLT M02 – MOTOR VOLTAGE

Motor Voltage Mismatch Fault

The configured voltage of the drive is greater than the

motor rated voltage. For example, a 400V-class drive

with a 200V-class motor.

Set the drive voltage to a lower value or replace motor with voltage

rating that matches the drive.

FLT M25 – COMMON BUS

DC Common Bus Fault

AC power was detected by the drive while configured

for shared DC operation.

• Check the drive power configuration from controller

• Check wiring

FLT M26 – RUNTIME ERROR

Runtime Error

The drive firmware encountered an unrecoverable

runtime error.

• Cycle control power

• Reset the drive

• Return drive for repair if fault continues

FLT M28 – SAFETY COMM

(2198-Hxxx-ERS2 drives only)

Safety Module Communication

Error

Communication with the safety hardware within the

drive has failed.

• Cycle control power

• Reset the drive

• Return drive for repair if fault continues