M0/m1 monitoring – Rockwell Automation 1747-BSN Backup Scanner Module User Manual

Page 183

Publication 1747-UM010B-EN-P - September 2003

M0-M1 Files and G Files B-3

M0/M1 Monitoring

The SLC 5/03, SLC 5/04, SLC 5/05 processors allow you to monitor the

actual state of each addressed M0/M1 address (or data table). The

highlighting appears normal when compared to the other processor

data files. The processor’s performance will be degraded to the degree

of M0/M1 referenced screen data. For example, if your screen has

only one M0/M1 element, degradation is minimal. If your screen has

69 M0/M1 elements, degradation is significant.

Transferring Data Between Processor Files and M0 or M1 Files

The processor does not contain an image of the M0 or M1 file. As a

result, you must edit and monitor M0 and M1 file data via instructions

in your ladder program. For example, you can copy a block of data

from a processor data file to an M0 or M1 data file or vice versa using

the COP instruction in your ladder program.

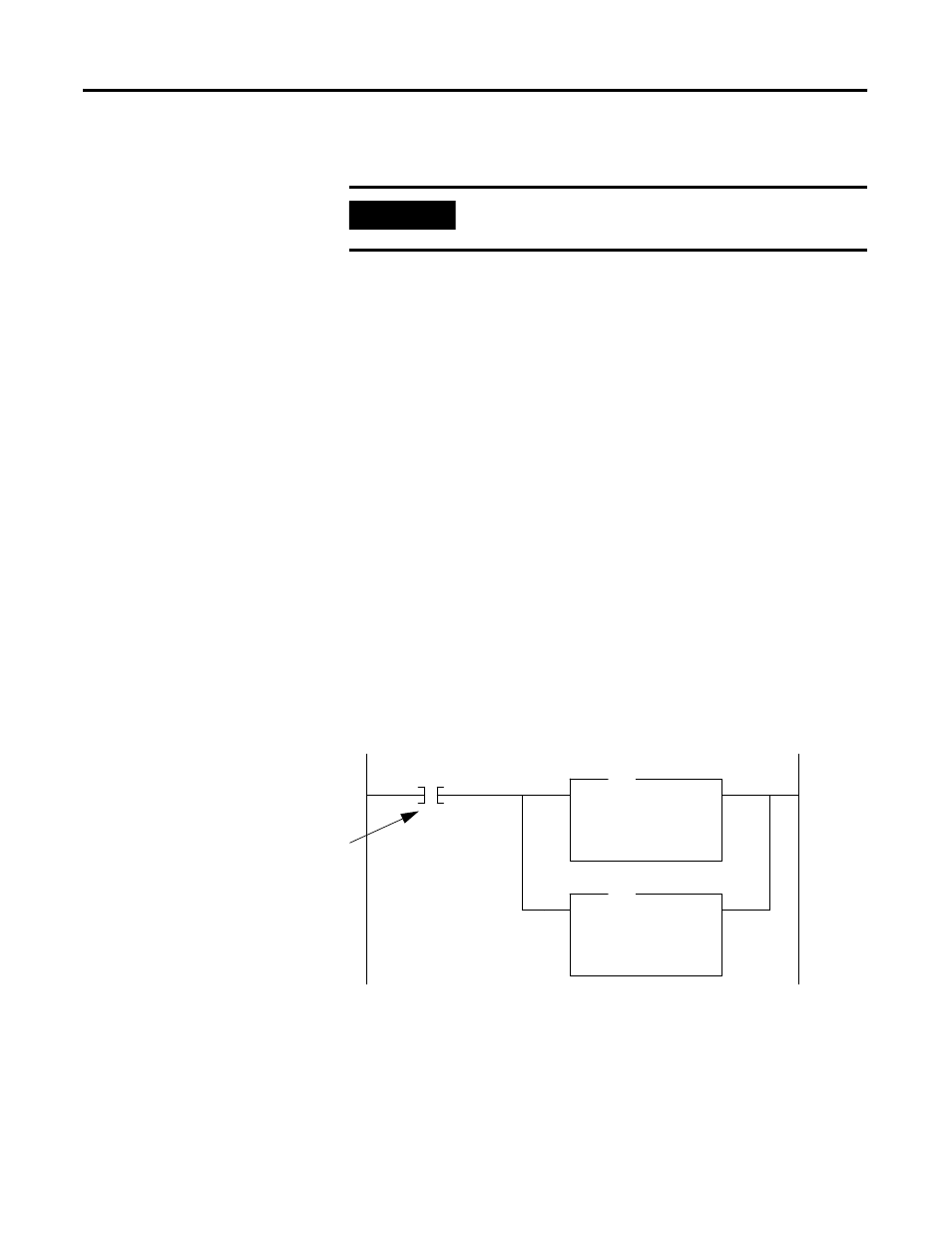

The COP instructions below copy data from a processor bit file and

integer file to an M0 file. For the example, assume the data is

configuration information affecting the operation of the specialty I/O

module.

IMPORTANT

This option is not supported by the SLC 5/02

processor.

S:1

15

COP

Copy File

Source

#B3:0

Dest

#M0:1.0

Length

16

COP

COP

Copy File

Source

#N7:0

Dest

#M0:1.16

Length

27

COP

First scan bit. It makes this rung

true only for the first scan after

entering Run mode.