2 configuration of the ecs user interface, 1 default setting of the ecs hardware inputs, Configuration of the ecs user interface -3 – Lenze EVS93xx FlyingSaw User Manual

Page 91: Default setting of the ecs hardware inputs -3, Flyingsaw, Program extensions/supplements

FlyingSaw

Program extensions/supplements

Prepared Solution Servo PLC / ECSxA 1.1 EN

page 8-3

8.2 Configuration

of

the ECS user interface

8.2.1

Default setting of the ECS hardware inputs

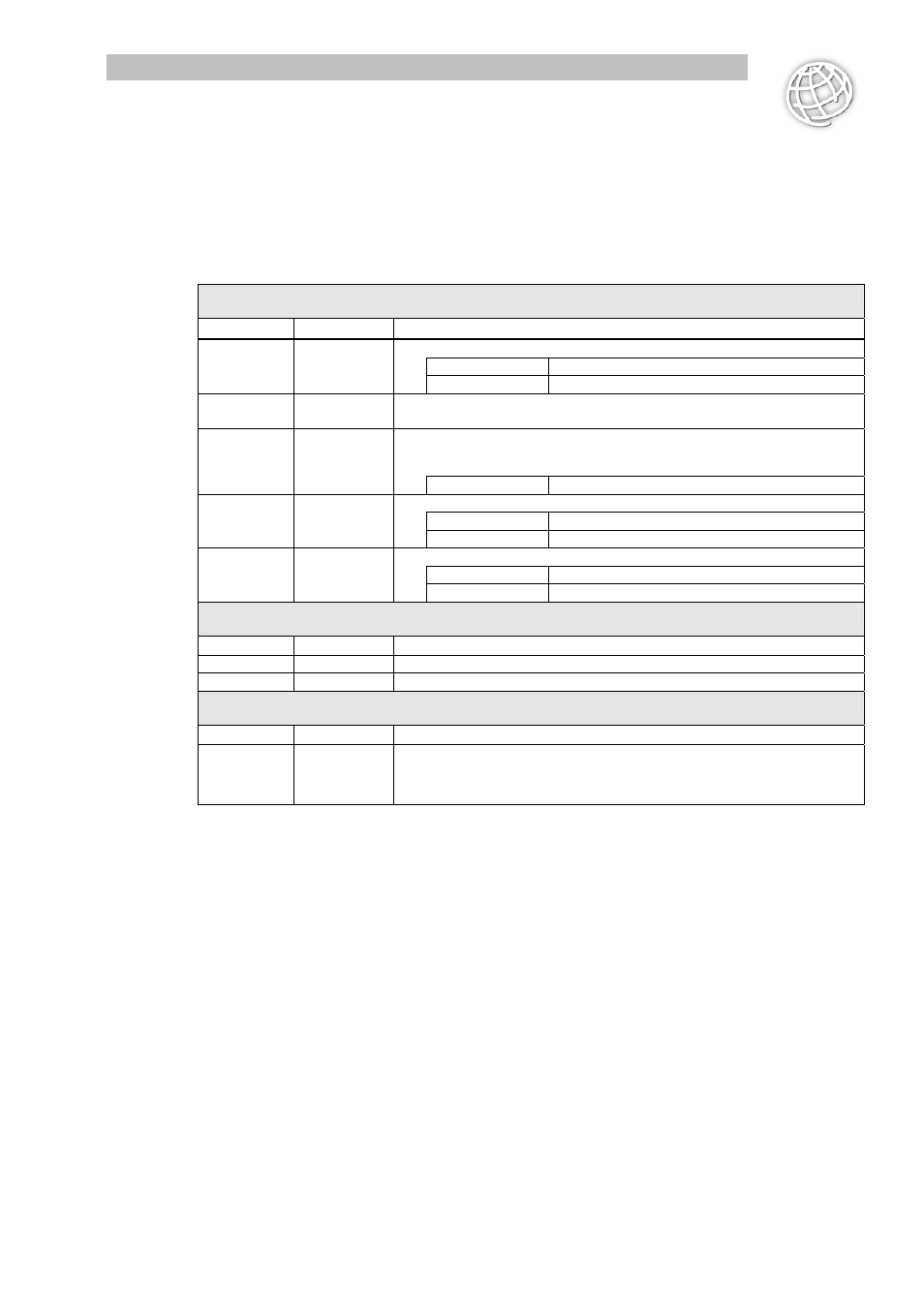

Digital inputs

(X6)

terminal signal

value/meaning

Controller enable

0V Inhibit servo controller

28

24V Enable servo controller

E1

DFIN_bTPReceived_b Touch probe input for mark-controlled synchronisation.

Note: The code C0428/000 must always be set to the value 1 so that the mark is detected using input E1

Signal from the homing switch

The signal is only relevant for the homing modes 0, 1, 2, 3, 4 and 5 – you will find further information on the

individual homing modes in chapter 2.12.1

E2

g_bHomingMark

24V => 0V Homing switch

Signal from the positive limit switch

0V Positive limit switch actuated

E3

g_bLimitSwitchPos

24V Positive limit switch not actuated

Signal from the negative limit switch

0V Negative limit switch not actuated

E4

g_bLimitSwitchNeg

24V Negative limit switch not actuated

Analog inputs

(X6)

terminal signal

value/meaning

1, 2

(not used)

3, 4

(not used)

Master frequency

input (X8)

terminal signal

value/meaning

X8

DFIN_nIn_v

Input of the master speed as phase difference signal:

The number of increments in the signal present on X8 can be set in the parameters using code C0425/000, however

a value for C0425/000 = 6 (16384[incr./rev]) should always be used to ensure the greatest possible resolution for the

master position.