2 application error messages, Application error messages -19, Flyingsaw – Lenze EVS93xx FlyingSaw User Manual

Page 141: Appendix

FlyingSaw

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

11-19

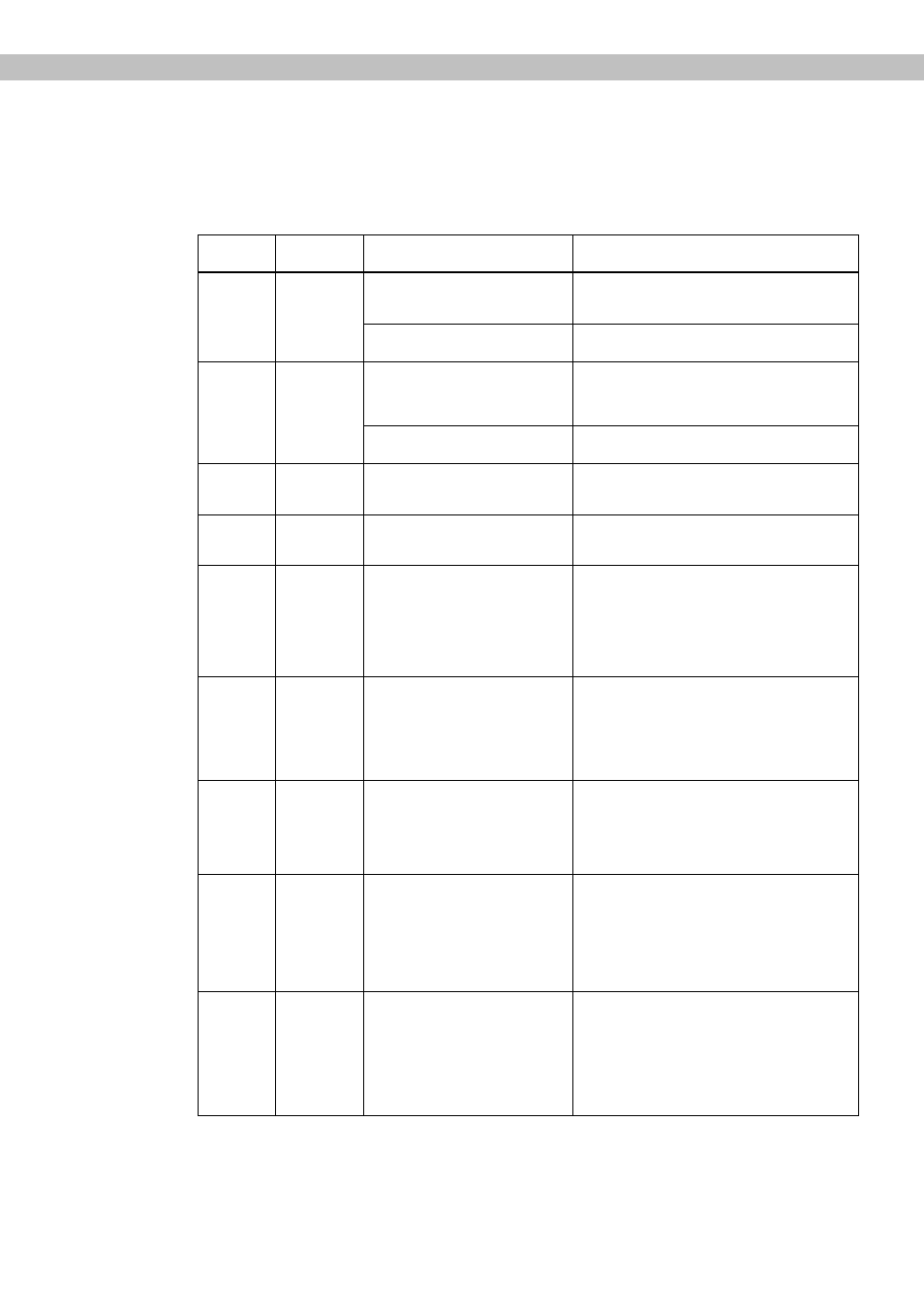

11.4.2

Application error messages

Error

number

Error code

Cause

Remedy

Positive limit switch actuated

Move clear from the positive limit switch:

Acknowledge the error message.

Move the drive in the negative direction, e.g. using

manual jogging until clear of the positive limit switch

400

PosLimit

Switch

Limit switch signal not connected to

terminal E2

Set the level inversion for the digital input E2 to

inverse logic (C0114/002 = 1) or

Hard wire the terminal E2 to 24V DC

401

NegLimit

Switch

Negative limit switch actuated

Move clear from the negative limit switch:

Move the drive in the positive direction, e.g. using

manual jogging until clear of the negative limit

switch

Limit switch signal not connected to

terminal E1

Set the level inversion for the digital input E1 to

inverse logic (C0114/001 = 1) or

Hard wire the terminal E1 to 24V DC

402

PosSWLimit

Positive software limit position has

reached/passed

Move the drive in the negative direction to the

permissible traversing range.

Set the limit value for the positive software limit

position (C3223/000) to a higher value.

403

NegSWLimit

Negative software limit position has

reached/passed

Move the drive in the positive direction to the

permissible traversing range.

Set the limit value for the negative software limit

position (C3224/000) to a lower value.

405

FollError

The drive cannot follow the setpoint,

the actual following error is greater

than the value set in the parameters in

C3218/001.

-

Increase current threshold in C0022/000 and as

a result increase the maximum torque

(CAUTION: pay attention to motor heating!)

-

Reduce dynamic requests

(accelerations/decelerations)

-

Increase following error limit in C3218/001

-

Check drive dimensioning as necessary

410

DriveNotRdy

Automatic operation has been

interrupted by a controller inhibit set

by the user.

-

Controller inhibit can be triggered using

terminal 28, a bus system (AIF or CAN bus), the

control codes C0040/000 and C0135/000 or the

system variables DCTRL_bCinh1_b and

DCTRL_bCinh2_b.

-

Re-enable the target system, acknowledge the

error and return the drive to the required

operating mode.

419

StateBusError Another drive axis connected to the

state bus has a fault. All controllers

connected are set to the error status

StateBusError using the terminals ST.

-

Identify the drive in the state bus

interconnection that has caused the error,

rectify the cause of the error and reset the error

on this drive

-

Then reset the state bus error on all other

drives that are connected to the state bus.

420

OU_MCTRL

Error

Automatic operation has been

interrupted by a brief overvoltage on

the DC bus.

An overvoltage on the DC bus is detected using the

system variable MCTRL_bOverVoltage_b: if this

error occurs proceed as follows:

-

Acknowledge the error.

-

Set the drive back to the required operating

mode.

To determine the cause of the error, refer to error

message no. 20 (OU) in the system error messages.

421

LU_MCTRL

Error

Automatic operation has been

interrupted by undervoltage on the

DC bus.

An undervoltage on the DC bus is detected using the

system variable MCTRL_bUnderVoltage_b: if this

error occurs proceed as follows:

-

Acknowledge the error.

-

Set the drive back to the required operating

mode.

To determine the cause of the error, refer to error

message no. 30 (LU) in the system error messages.