Flyingsaw, Functions – Lenze EVS93xx FlyingSaw User Manual

Page 49

FlyingSaw

Functions

Prepared Solution Servo PLC / ECSxA 1.1 EN

page 3-36

The signal sources for the data words (shown in the illustration as Word 0, Word 1, Word 2 and

Word 3

) are dependent on the operating mode C4000/000:

Signal source

Word 0

Word 1

Word 2

Word 3

C4000/000 = 0

-

C4135/000

C4000/000 = 1

CAN1_wDctrlCtrl CAN1_nInW1_a CAN1_nInW2_a CAN1_nInW3_a

C4000/000 = 2

CAN2_nInW1_a CAN2_nInW2_a CAN2_nInW3_a CAN2_nInW4_a

C4000/000 = 3

CAN3_nInW1_a CAN3_nInW2_a CAN3_nInW3_a CAN3_nInW4_a

C4000/000 = 4

AIF1_wDctrlCtrl AIF1_nInW1_a AIF1_nInW2_a AIF1_nInW3_a

C4000/000 = 5

AIF2_nInW1_a AIF2_nInW2_a AIF2_nInW3_a AIF2_nInW4_a

C4000/000 = 6

AIF3_nInW1_a AIF3_nInW2_a AIF3_nInW3_a AIF3_nInW4_a

The figure on the previous page of the 32-bit application control word (word 3 and word 4)

shows the factory-set default configuration. The user can also adapt the configuration of the

application control word using the codes C4010/001 to C4010/032 to suit specific requirements.

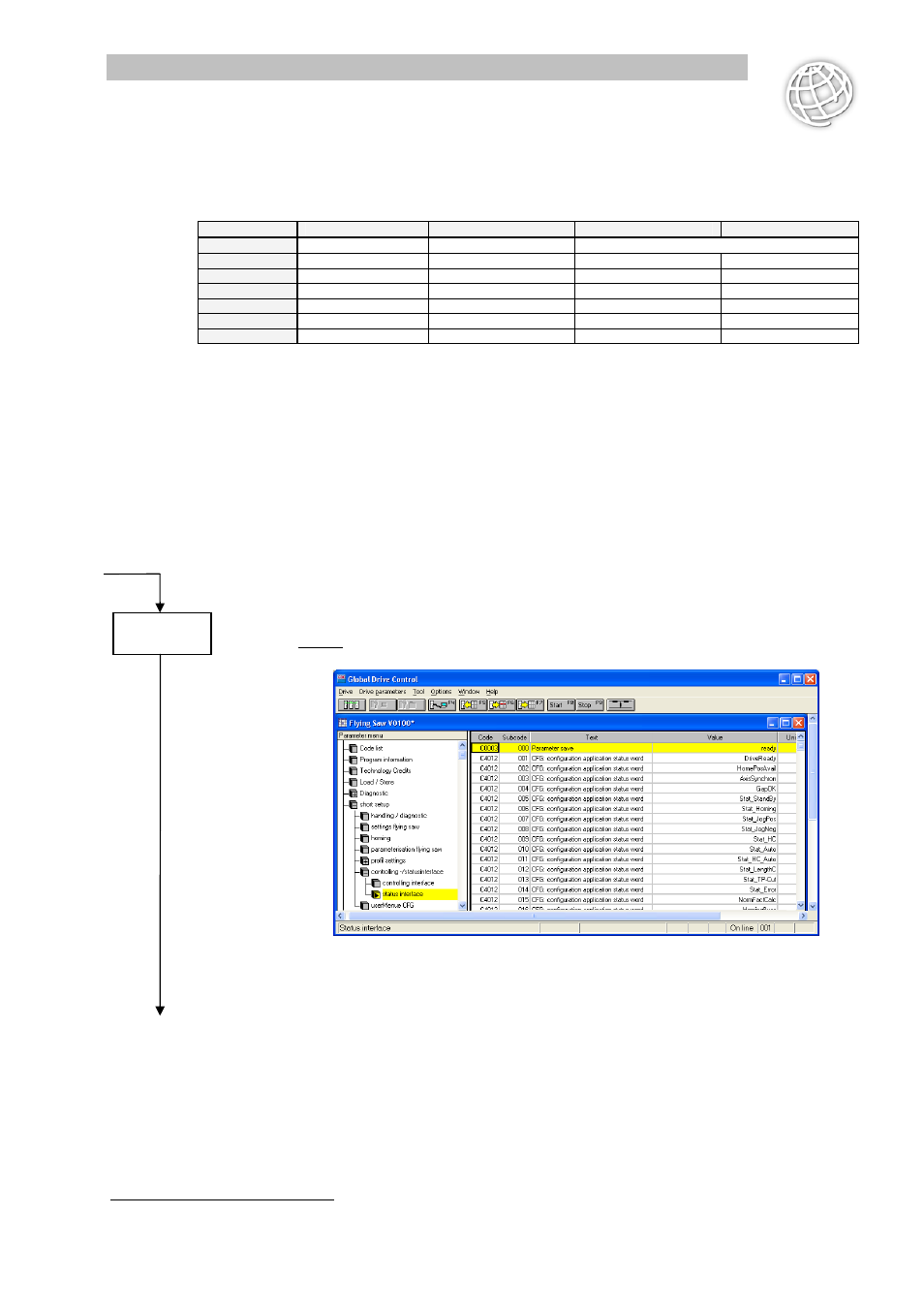

As an example it is shown in the following how the application control word can be re-configured

bit by bit with the aid of the parameter setting software GDC:

Select the code C4010/00x allocated to the function to be configured.

Example: To define the control signal for positive manual control on the x axis the code C4010/003 is

available:

Start

Step 1