5 function block lengthcalculation, Function block lengthcalculation -8, Flyingsaw – Lenze EVS93xx FlyingSaw User Manual

Page 106: Description of the function blocks

FlyingSaw

Description of the function blocks

Prepared Solution Servo PLC / ECSxA 1.1 EN

10-8

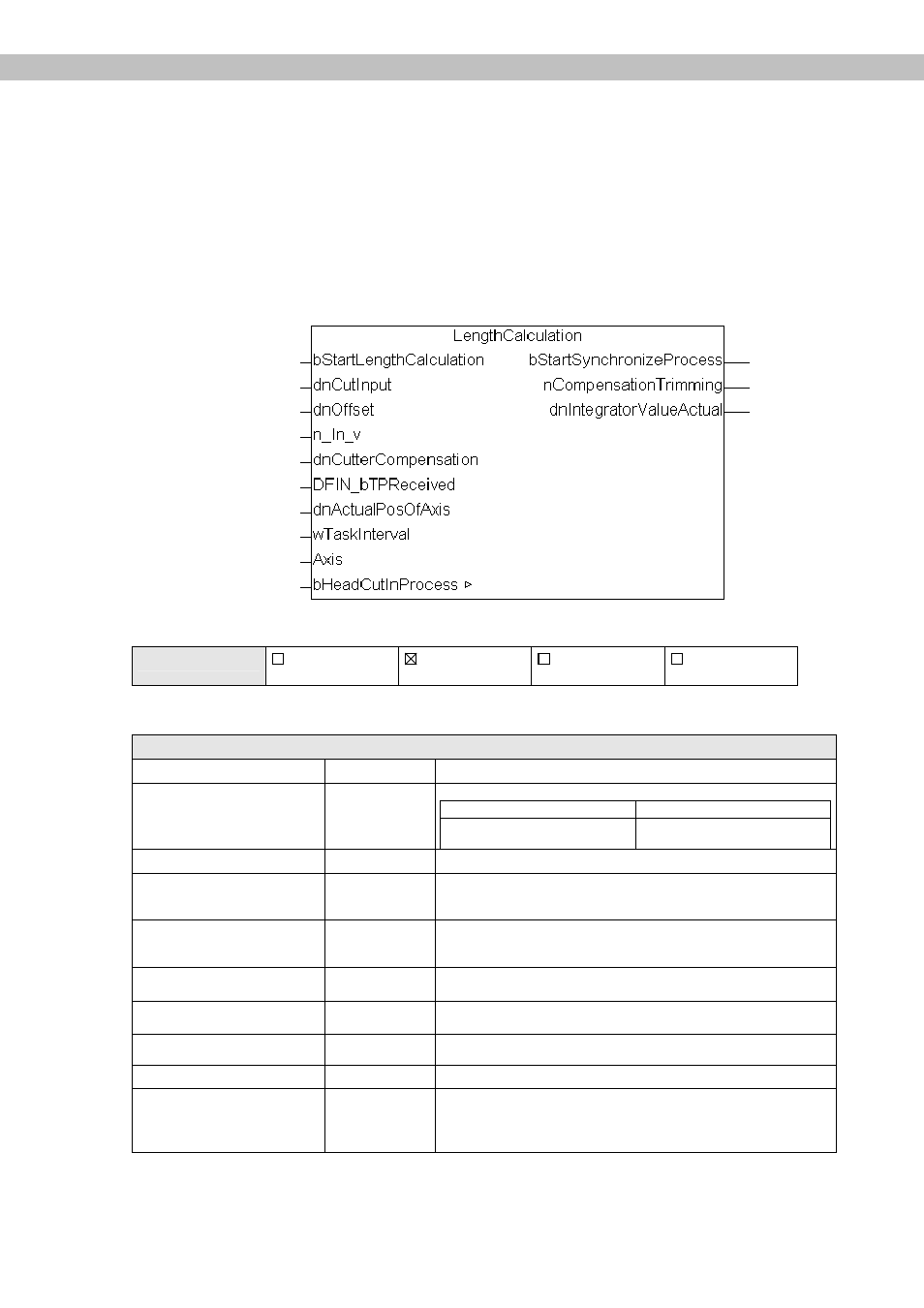

10.5 Function

block

LengthCalculation

Based on the length entered, the block LengthCalculation calculates the start signals for the

synchronisation to the master speed.

Task information

Can be called in:

Cyclic task

Time-controlled task

(INTERVAL)

Event-controlled task

(EVENT)

Interrupt task

Inputs

(Variable type: VAR_INPUT)

Identifier Data

type

Value/meaning

bStartLengthCalculation BOOL

Start the length calculator

TRUE

Start the length calculator

FALSE

Stop the length calculator. The length

calculator is initialised with zero internally.

dnCutInputInc

DINT

Input for specifying the set length. The set length is defined in increments.

dnOffset DINT

Input for the offset.

The offset is calculated in the function block OffsetCalculation and must be connected to

this input.

n_In_v INT

Master frequency specified in the unit [inc/ms].

The master frequency is calculated using the normalisation factor and must be connected to

the output of the function block MasterFrequency.

dnCutterCompensation DINT

Input for width of cut compensation.

The width of cut is defined in the application unit [unit].

DFIN_bTPReceived BOOL

Input for the DFIN touch probe.

The variable is to be connected to the input DFIN_bTPReceived_b on the SB DFIN

dnActualPosOfAxis DINT

Input for the actual position of the flying saw. If a top cut is performed away from the initial

position, this position is added to the calculation and taken into account on the next cut.

wTaskInterval WORD

Task interval. This variable must be linked to System_Flag SYSTEM_wTaskInterval

Axis MC_AXIS_REF

Machine parameters

¾

Data structure with elements that contain the machine parameters in the

internal measuring system.

¾

Connect this input to a global variable written by the FB L_MCMachineData