8 program extensions/supplements, 1 configuration of the servoplc user interface, 1 default setting of the servoplc hardware inputs – Lenze EVS93xx FlyingSaw User Manual

Page 89: Program extensions/supplements -1, Configuration of the servoplc user interface -1, Default setting of the servoplc hardware inputs -1, Flyingsaw, Program extensions/supplements

FlyingSaw

Program extensions/supplements

Prepared Solution Servo PLC / ECSxA 1.1 EN

page 8-1

8 Program

extensions/supplements

Program extensions and supplements are possible if the programmable variant is used as the

basis for the Prepared Solution. The program is edited using the Lenze software Drive PLC

Developer Studio (DDS), version V2.2 or later. The chapters that follow require basic knowledge

of the IEC programming languages and the configuration of programmable logic controllers.

8.1 Configuration

of

the

ServoPLC user interface

8.1.1

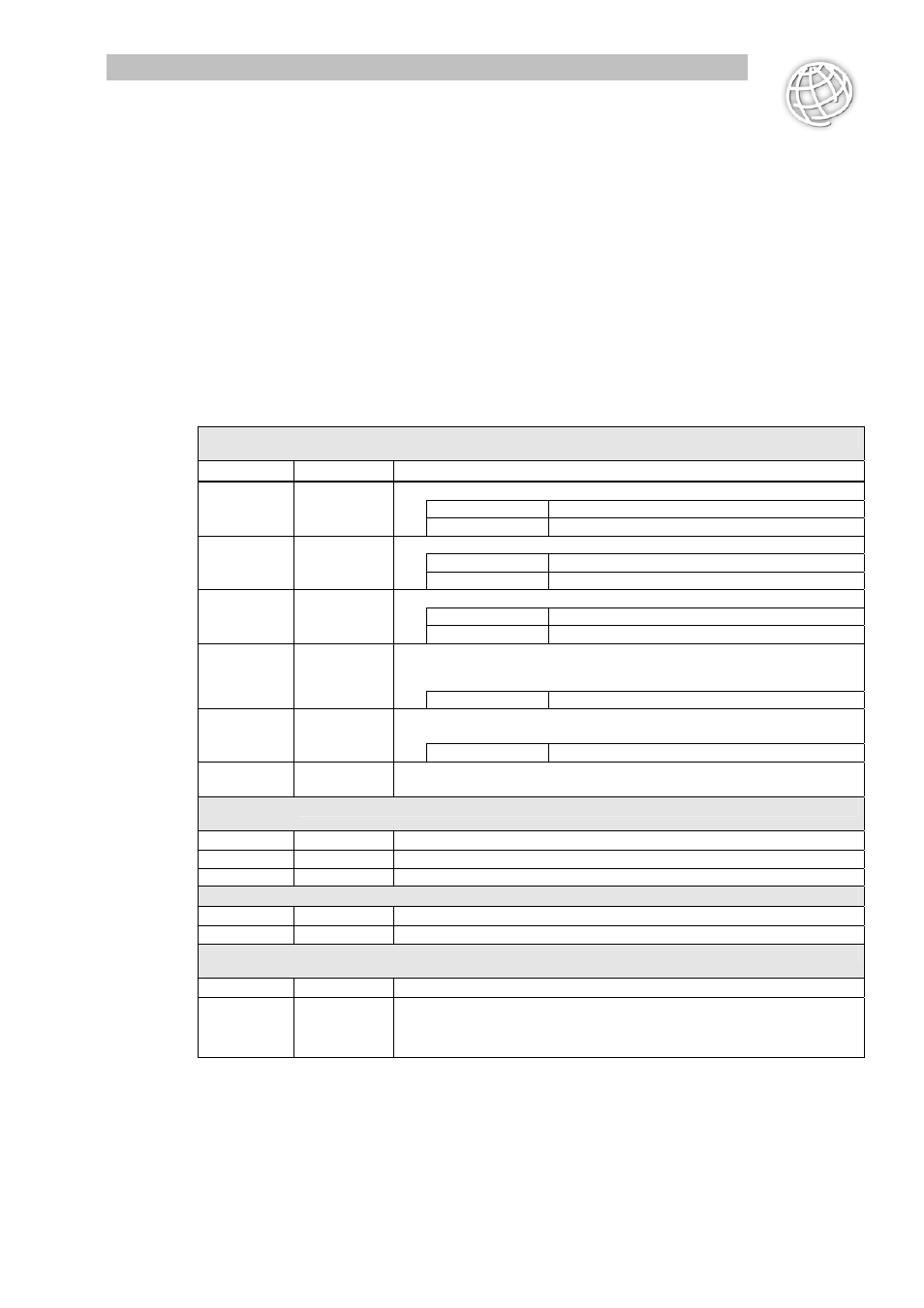

Default setting of the ServoPLC hardware inputs

Digital inputs

(X6)

Terminal Signal

Value/meaning

Controller enable

0V Inhibit servo controller

28

24V Enable servo controller

Signal from the positive limit switch

0V Positive limit switch actuated

E1

g_bLimitSwitchPos

24V Positive limit switch not actuated

Signal from the negative limit switch

0V Negative limit switch actuated

E2

g_bLimitSwitchNeg

24V Negative limit switch not actuated

Signal from the homing switch

The signal is only relevant for the homing modes 0, 1, 2, 3, 4 and 5 – you will find further information on the

individual homing modes in chapter 2.12.1

E3

g_bHomingMark

24V => 0V Homing switch

Cut done signal

The signal is sent from the processing tool to the application. The tool is then returned to the initial position

E4

g_bCutReady

0V => 24V Cut done signal

E5

DFIN_bTPReceived_b Touch probe input for mark-controlled synchronisation.

Note: The code C0428/000 must always be set to the value 1 so that the mark is detected using input E5

Analog inputs

(X6)

Terminal Signal

Value/meaning

1, 2

(not used)

3, 4

(not used)

State bus

Terminal Signal

Value/meaning

ST

(not used)

Master frequency

input (X9)

Terminal Signal

Value/meaning

X9

DFIN_nIn_v

Input of the master speed as phase difference signal:

The number of increments in the signal present on X9 can be set in the parameters using code C0425/000, however

a value for C0425/000 = 6 (16384[incr./rev]) should always be used to ensure the greatest possible resolution for the

master position.