Flyingsaw, Appendix – Lenze EVS93xx FlyingSaw User Manual

Page 136

FlyingSaw

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

11-14

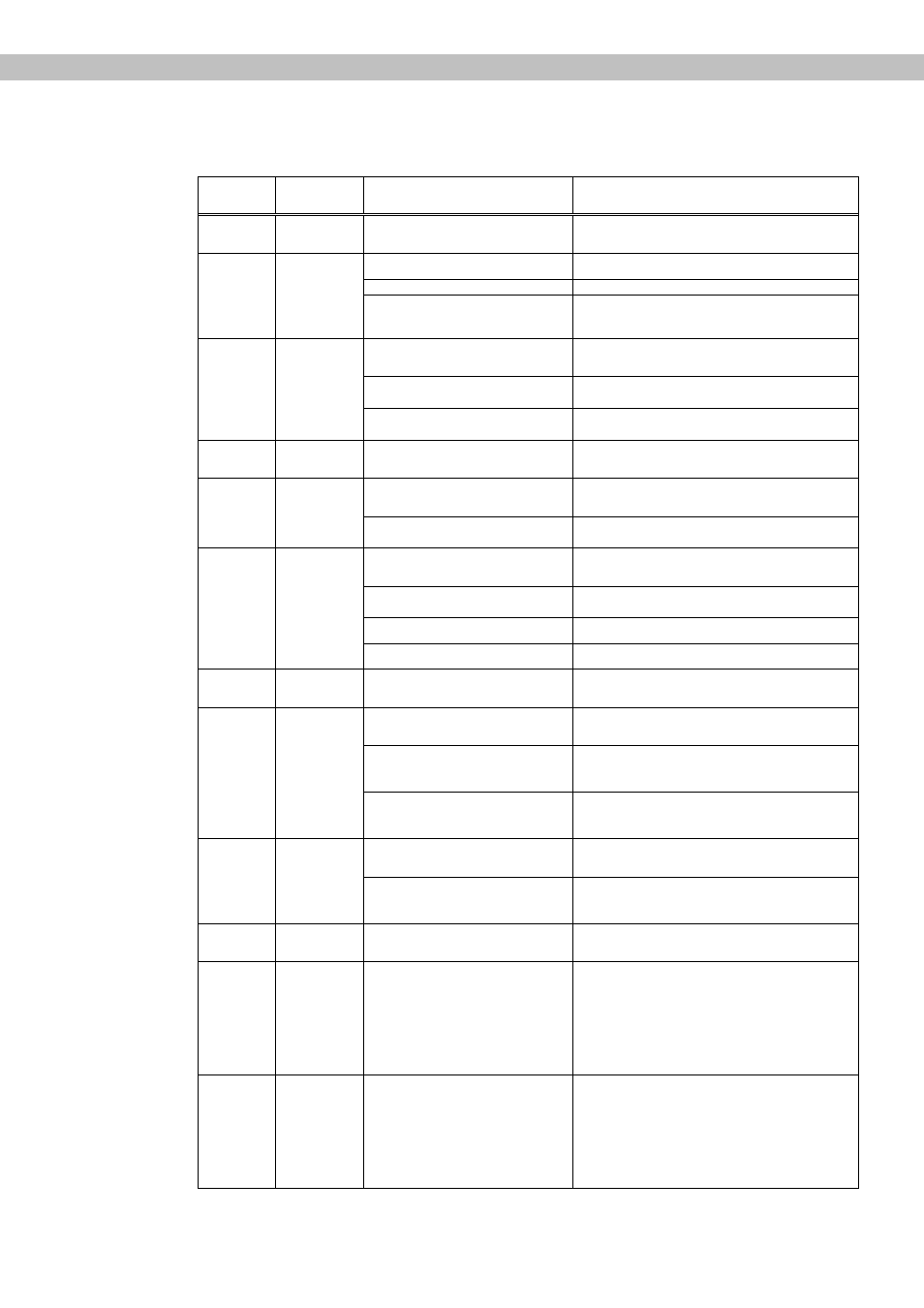

Error

number

Error code

Cause

Remedy

30

LU

DC-bus voltage has dropped below the

value set in code C0173/000

Check mains voltage.

Check mains contactor/fuses.

In case of DC supply: check power supply module.

A current-carrying motor phase has

failed

Disconnect motor and measure windings.

Disconnect supply cable and check for continuity.

The current threshold is set too low

Increase current threshold in code C0599/000.

32

LP1

This monitoring is not suitable for

- synchronous

servo

motors

-

Field frequencies above 480Hz

Deactivate monitoring using code C0597/000 = 3.

Ambient temperature too high (T

U

> 40°C

or 50°C, depending on device

type/power reduction)

Leave drive controller to cool down and provide

improved ventilation (control cabinet fan?).

Check ambient temperature in the control cabinet.

Heatsinks are heavily soiled

Clean heatsinks and protect against renewed soiling.

50

OH

Mounting position of the drive controller

Check the mounting position of the controller and the

stipulated minimum distances top and bottom.

51

OH1

Internal temperature > 90 degrees C

Leave drive controller to cool down and provide

improved ventilation (control cabinet fan?).

Check ambient temperature in the control cabinet

Overtemperature detection by PTC/KTY:

motor too hot due to continuous

overload/ overcurrent

Check drive dimensioning.

53

OH3

No PTC/KTY connected Connect

PTC/KTY.

Deactivate the OH3 error using code C0583/000 = 3).

Ambient temperature too high (T

U

> 40°C

or 50°C, depending on device

type/power reduction)

Leave drive controller to cool down and provide

improved ventilation (control cabinet fan?)

Check ambient temperature in the control cabinet.

Heatsinks are heavily soiled

Clean heatsinks and protect against renewed soiling.

Mounting position of the drive controller

Check the mounting position of the controller and the

stipulated minimum distances top and bottom.

54

OH4

A value that is too low has been set in

the parameters using code C0122/000

Increase value in code C0122/000.

55

OH5

Temperature inside the controller >

C0124

Leave drive controller to cool down and provide

improved ventilation (control cabinet fan?).

Check ambient temperature in the control cabinet

Overtemperature detection by PTC/KTY:

motor too hot due to continuous

overload/ overcurrent

Check drive dimensioning.

No PTC/KTY connected

Connect PTC/KTY.

Deactivate the OH7 error using code C0584/000 = 3).

57

OH7

A value that is too low has been set in

the parameters using code C0121/000

Increase value in code C0121/000.

Overtemperature detection by

temperature contact: motor too hot due

to continuous overload/ overcurrent

Check drive dimensioning.

58

OH8

No temperature contact connected

Connect temperature contact to terminals T1/T2.

Deactivate the OH8 error using code C0585/000 = 3).

61

CE0

Malfunction on the transfer of control

commands over the AIF interface (e.g.

PROFIBUS DP)

Fix automation module firmly.

Fasten automation module in place.

62

CE1

CAN-IN1 channel is not receiving any

data or is receiving erroneous data

Check CAN bus cable (connector X4)

Check CAN terminating resistor (on the first and last

CAN station)

Check configuration of the CAN node sending on CAN-

IN1

Check power supply to the CAN node sending on CAN-

IN1

Check monitoring time in code C0357/001 and increase

if necessary

63

CE2

CAN-IN2 channel is not receiving any

data or is receiving erroneous data

Check CAN bus cable (connector X4)

Check CAN terminating resistor (on the first and last

CAN station)

Check configuration of the CAN node sending on CAN-

IN2

Check power supply to the CAN node sending on CAN-

IN2

Check monitoring time in code C0357/002 and increase

if necessary