Flyingsaw, Appendix – Lenze EVS93xx FlyingSaw User Manual

Page 138

FlyingSaw

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

11-16

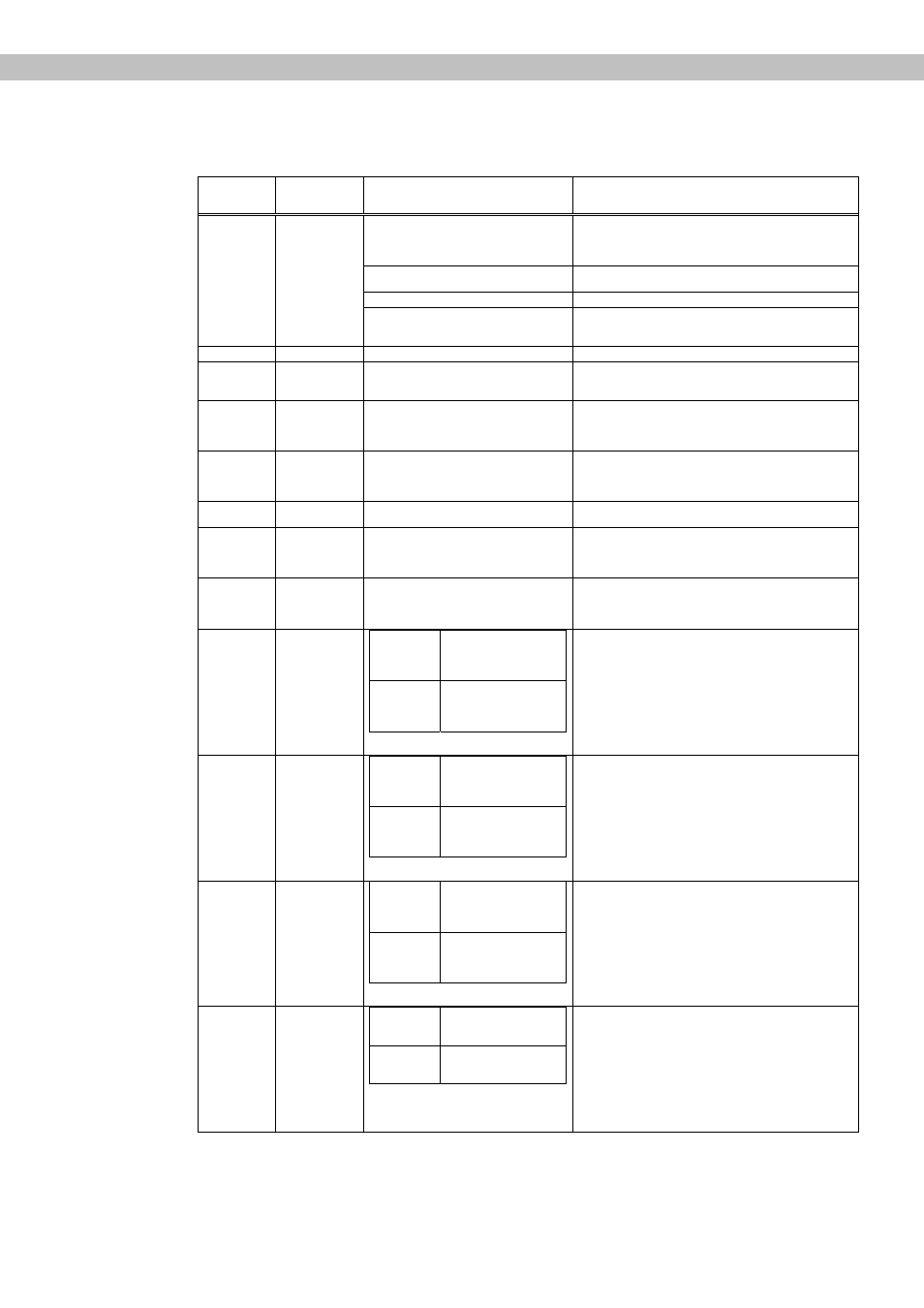

Error

number

Error code

Cause

Remedy

On the sin/cos encoder or the controller

(terminal X8) the connector has been

removed (open circuit) or is not correctly

fitted

Check the connector on the controller (terminal X8) and

on the encoder system for correct seating

In the connecting cable to the sin/cos

encoder there is a fault

Check the connector assignment and core assignment

on the cable for correct pin assignment

Fault in the encoder electronics

Replace faulty encoder type.

88

Sd8

Note: Particularly for monitoring the encoder on a

synchronous machine set using

Code C0580 = 0 the error response "error" (TRIP).

89

PL

Error during rotor position adjustment

91

EEr

A digital signal linked to the system

variable DCTRL_bTripSet_b is carrying

the state TRUE

Check signal source in system variable

DCTRL_bTripSet_b

. The "Eer" error can be reset if this

signal source has adopted the state FALSE.

105

H05

Consultation with Lenze necessary (service hotline:

(+49) 5154 82-1111)

Reset only possible by mains switching, if error cannot

be reset: replace controller or send for repair

107

H07

An incorrect power section has been

detected during the initialisation of the

controller

Consultation with Lenze necessary (service hotline:

(+49) 5154 82-1111)

Reset only possible by mains switching, if error cannot

be reset: replace controller or send for repair

108

HO8

Extension board not fitted correctly or not

supported by the program

Check the settings in the system controller as to which

extension board is selected.

110

H10

Sensor for the heatsink temperature

measurement is providing undefined

values, an internal thermocouple may be

faulty

Consultation with Lenze necessary (service hotline:

(+49) 5154 82-1111)

Reset only possible by mains switching, if error cannot

be reset: replace controller or send for repair

111

H11

Sensor for the internal temperature

measurement is providing undefined

values, an internal thermocouple may be

faulty

Consultation with Lenze necessary (service hotline:

(+49) 5154 82-1111)

Reset only possible by mains switching, if error cannot

be reset: replace controller or send for repair

122

CE11

FIF-CAN1 FIF-CAN1_IN

(monitoring time can

be adjusted using

C2457/1)

CANaux1 CANaux1_IN

(monitoring time can

be adjusted using

C2457/1)

Check baud rate of all nodes

Check wiring:

-

Check bus terminating resistors

-

Check shield connection on the cables

- Check

PE

connection

-

Check bus load (e.g. using software tool

PCANView)

Reduce baud rate (CAUTION: pay attention to CAN bus

cable lengths)

123

CE12

FIF-CAN2 FIF-CAN2_IN

(monitoring time can

be adjusted using

C2457/2)

CANaux2 CANaux2_IN

(monitoring time can

be adjusted using

C2457/2)

Check baud rate of all nodes

Check wiring:

-

Check bus terminating resistors

-

Check shield connection on the cables

- Check

PE

connection

-

Check bus load (e.g. using software tool

PCANView)

Reduce baud rate (CAUTION: pay attention to CAN bus

cable lengths)

124

CE13

FIF-CAN3 FIF-CAN3_IN

(monitoring time can

be adjusted using

C2457/3)

CANaux3 CANaux3_IN

(monitoring time can

be adjusted using

C2457/3)

Check baud rate of all nodes

Check wiring:

-

Check bus terminating resistors

-

Check shield connection on the cables

- Check

PE

connection

-

Check bus load (e.g. using software tool

PCANView)

Reduce baud rate (CAUTION: pay attention to CAN bus

cable lengths)

125

CE14

FIF-CAN

BUS-OFF status FIF-

CAN (too many faulty

telegrams received)

CANaux

BUS-OFF status FIF-

CAN (too many faulty

telegrams received)

Check baud rate of all nodes

Check wiring:

-

Check bus terminating resistors

-

Check shield connection on the cables

- Check

PE

connection

-

Check bus load (e.g. using software tool

PCANView)

Reduce baud rate (CAUTION: pay attention to CAN bus

cable lengths)