3 codes of the prepared solution, 1 table of application codes, Codes of the prepared solution -7 – Lenze EVS93xx FlyingSaw User Manual

Page 129: Table of application codes -7, Flyingsaw, Appendix

FlyingSaw

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

11-7

11.3

Codes of the Prepared Solution

11.3.1

Table of application codes

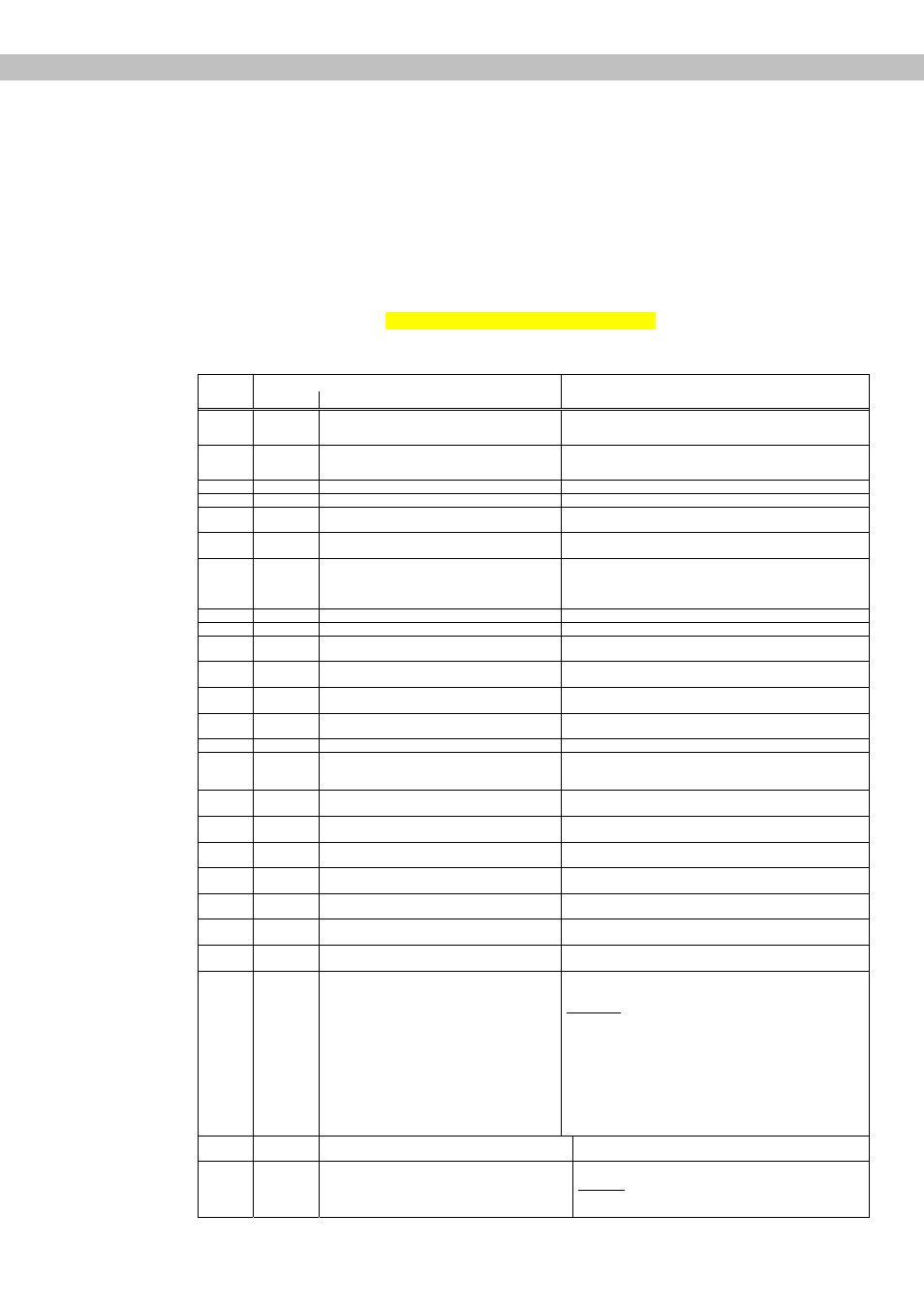

Along with system codes (see documentation 9300ET ServoPLC), with the Prepared Solution

important settings for the machine function can be made using application codes from the range

C3000/000.

Possible settings:

Code

Default Selection

Comment

C3000

0

0: Not inverted

1: Inverted

Inversion of the motor mounting position

C3001

0

0: Not inverted

1: Inverted

Inversion of the master frequency (DFIN). Necessary if the

measuring wheel is mounted counter-rotating.

C3003

1

0...

{1}

... 65536 Gearbox factor numerator of measuring wheel

C3004

1

0...

{1}

... 65536 Gearbox factor denominator of measuring wheel

C3005 1 0...

{1

[units]}

...

2147483647

Circumference of the measuring wheel

C3006 1 0...

{1

[Inc/rev]}

...

2147483647

Number of increments from the encoder connected to the

measuring wheel

C3007 7500000

0...

{1

[units]}

...

2147483647

Entry of the set cut length. The entry is made in the format cut

length in units * 10000.

Example: 1234.56 mm set length, entry in code: 12345600

units.

C3009

100

0...

{1[ms]}

... 32767 Delay on the signal "axis synchronised"

C3010

500

0...

{1[Inc/ms]}

... 32767 Simulation speed (simulation of the master frequency input)

C3012 1500

0...

{1

[ms]}

...

4294967295

Flying saw acceleration time, during the synchronising

process

C3013 2500

0

{1

[ms]}

...

4294967295

Flying saw deceleration time, after the synchronous

movement

C3014

5.0000

0.0000

{1 [unit]}

214000.0000 Length of the gap that is to be made after processing the

material

C3015

0.0000

0.0000

{1 [unit]}

214000.0000 Mark detection offset. Distance between mark detection and

flying saw initial position.

C3016

0.0000

0.0000

{1 [unit]}

214000.0000 Width of cut compensation

C3017

0

0: Not activated

1: Activated

Monitoring of the mark detection. Length between the marks

is monitored using the length calculator and a cut "forced" if a

mark is not detected.

C3100 500.0000

-214000.0000...

{0.0001

[units/s]}

...

214000.0000

Speed for manual movement of the axis (inching operation,

valid for positive and negative inching)

C3101 750.0000

-214000.0000...

{0.0001

[units/s^2]}

...

214000.0000

Acceleration for manual movement of the axis (inching

operation, valid for positive and negative inching)

C3102 750.0000

-214000.0000...

{0.0001

[units/s^2]}

...

214000.0000

Deceleration for manual movement of the axis (inching

operation, valid for positive and negative inching)

C3200 0.0000

-214000.0000... {0.0001

[units]}

...

214000.0000

Position of the return movement profile. Movement to the

initial position. The initial position should be home position!

C3201 1200.0000

-214000.0000...

{0.0001

[units/s]}

...

214000.0000

Speed for the return movement profile for the initial position

movement

C3202 750.0000

-214000.0000...

{0.0001

[units/s^2]}

...

214000.0000

Acceleration for the return movement profile for the initial

position movement

C3203 750.0000

-214000.0000...

{0.0001

[units/s^2]}

...

214000.0000

Deceleration for the return movement profile for the initial

position movement

0: >_Rn_MP/TP

1: <_Rn_MP/TP

8: >_MP/TP

C3213 0

9: <_MP/TP

Definition of the homing mode:

Symbology:

>

Movement in positive direction

<

Movement in negative direction

Lp

Positive limit switch

Ln

Negative limit switch

Rp

Positive edge on the homing switch

Rn

Negative edge on the homing switch

MP/TP

Zero pulse from the motor feedback system or

touch-probe edge on a digital input

C3218

10.0000

0.0001... {0.0001

[units]}

... 214748.0000 Entry of the following error shutdown limit

C3223

0.0000

0... {0.0001

[units]}

... 214748.0000 Limit position for the positive software limit

Comment: software limits are only active if the home

position for the axis is known and the limits are not set to

zero.