Electrical installation, Motor with kty thermal sensor, We recommend to use lenze system cables for wiring – Lenze EVF9333 User Manual

Page 196

Electrical installation

Standard devices in the power range 75 ... 90 kW

Motor connection

l

196

EDKVF9333V DE/EN/FR 7.1

Characteristics of the connection for motor temperature monitoring:

Terminals T1, T2

Connection

l

PTC thermistor

– PTC thermistor with defined tripping temperature (acc. to DIN 44081 and

DIN 44082)

l

Thermal contact (NC contact)

– Thermostat as NC contact

Tripping point

l

Fixed (depending on the PTC/thermal contact)

l

PTC: R

J

>

1600

W

l

Configurable as warning or error (TRIP)

Notes

l

Monitoring is not active in the Lenze setting.

l

If you do not use a Lenze motor, we recommend the use of a PTC thermistor up

to 150°C.

T1

T2

PE

U

V

W

2

3

4

M4 x 12: 2.5 Nm (22.1 lb-in)

M5 x 12: 3 Nm (26.5 lb-in)

U, V, W,

PE

M10

30 Nm

264 lb-in

1

0

T1

T2

2.5 Nm

22.1 lb-in

5

}

+

PE

9300std032

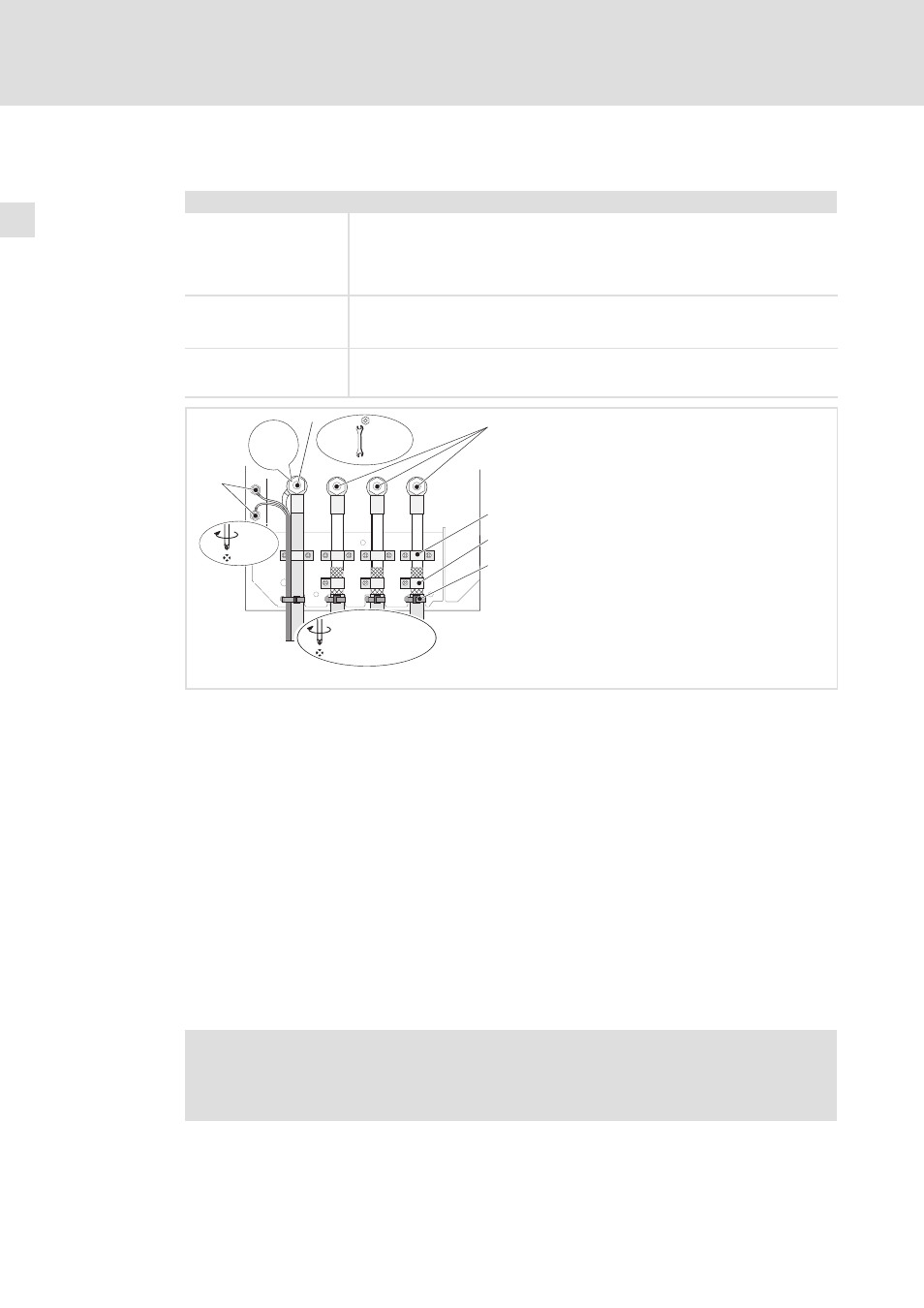

Fig. 5−22

Motor connection with PTC thermistor or thermal contact (NC contact)

0 PE stud

PE cable connection with ring cable lug

1 U, V, W

Motor cable connection

Check the correct polarity. Observe maximum length of the motor cable.

Max. connectable cable cross−section: 240 mm

2

with ring cable lug

2 Cable clamps for strain relief of motor cable

Fasten cable clamps with M4 × 12 mm screws

3 Shield clamps

Place shields of motor cable with large surface on the shield sheet and fasten with shield

clamps and M5 × 12 mm screws

4 Cable ties for additional strain relief of motor cable

5 T1, T2 for motor temperature monitoring

Cable connection for PTC thermistors or thermal contacts (NC contacts)

Place shield with large surface on PE stud

Motor with KTY thermal sensor

)

Note!

ƒ

We recommend to use Lenze system cables for wiring.

ƒ

For self−made cables only use cables with shielded cores twisted in pairs.