Festo elgl-en 0904nh – Festo Линейный привод ELGL-LAS User Manual

Page 67

66

FESTO ELGL-en 0904NH

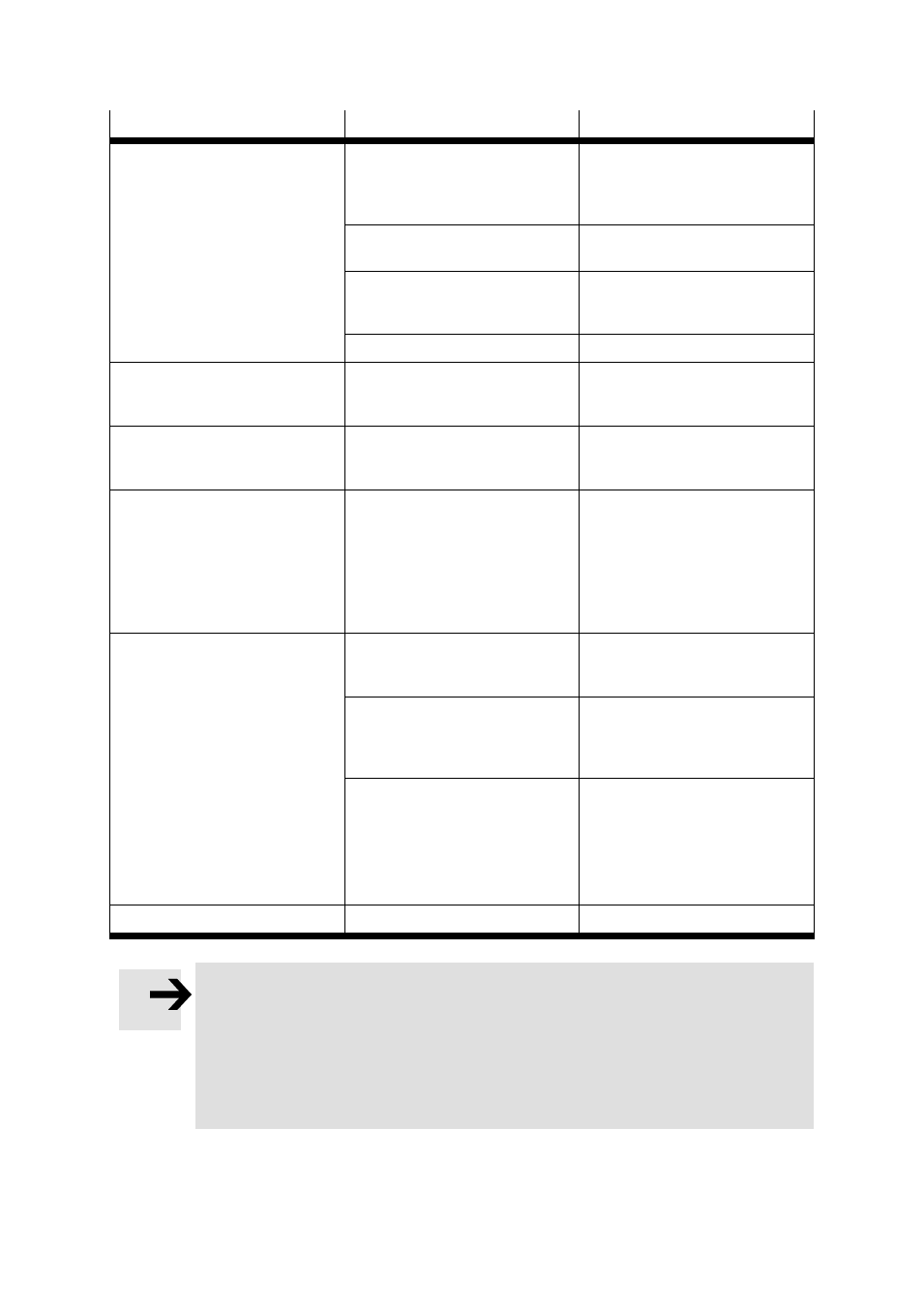

Fault

Possible cause

Remedy

Linear axis not responding

Temperature monitoring active

Observe permitted loading values

(take into account temperature

fluctuations during course of

year)

Incorrect parametrisation

Check parameters in the control-

ler

Linear axis is behind the end

position / homing fault

Manually push the linear axis out

of the end position (air on, power

off!)

Not enabled

Apply 24 V to enable input

Malfunction in the commutation

point search

Unfavourable resonance for the

selected

commutation

angle

process

Change

commutation

angle

search process in FCT or change

parametrisation.

Uneven force development in

relation to the direction of move-

ment

The commutation angle is not

correct

Change

commutation

angle

search process in FCT or change

parametrisation

Uncontrolled movements

Defects on the measuring head

and/or measuring tape, e.g. due

to mechanical, electrical or mag-

netic damage

Check the distance of the measur-

ing head to the measuring tape

(limit value <0.8 mm over the

entire area of movement).

If this is otherwise the case, al-

ways consult the Festo service

department

Abrasive marks on the stator/

increased friction

The function of the air cushion

bearing is limited in that the air

pressure is too low

Increase the air pressure to a

min. 4 bar

Distortion in stator or the slide

during operation, e.g. due to the

load being too great or thermal

deformation

Correct alignment and stress-fee

assembly of stator and effective

load; check the flatness using

straight-edge

Function of the air cushion bear-

ing is limited due to blocked noz-

zles, e.g. oily or otherwise con-

taminated compressed air

Please consult the Festo service

department for having the bear-

ing nozzles replaced.

Make sure the compressed air is

filtered and oil-free by using 5 µm

filters

Note

Please also check the error messages and warnings from the controller and

parametrisation software in the event of malfunctions.

Should you still need help, then please don't hesitate to contact the Festo

service department and please don't forget to have the device details

(type/serial number), as well as the configuration data, project files etc. at

hand along with an (as far as possible) exact description of the error.