Troubleshooting – Festo Линейный привод ELGL-LAS User Manual

Page 66

65

FESTO ELGL-en 0904NH

12 Troubleshooting

Warning

Dangerous voltage

Work on a live system may only be carried out by experienced, expert electri-

cal technicians and is only permitted for the purpose of error diagnosis.

For fault-finding in a live system, mobile protective equipment (e.g. a protec-

tive isolating transformer) has to be made available.

Depending on the type of work being carried out and the ambient conditions,

other measures and auxiliary means, such as insulated tools, insulated safety

gloves, insulated location, may be required.

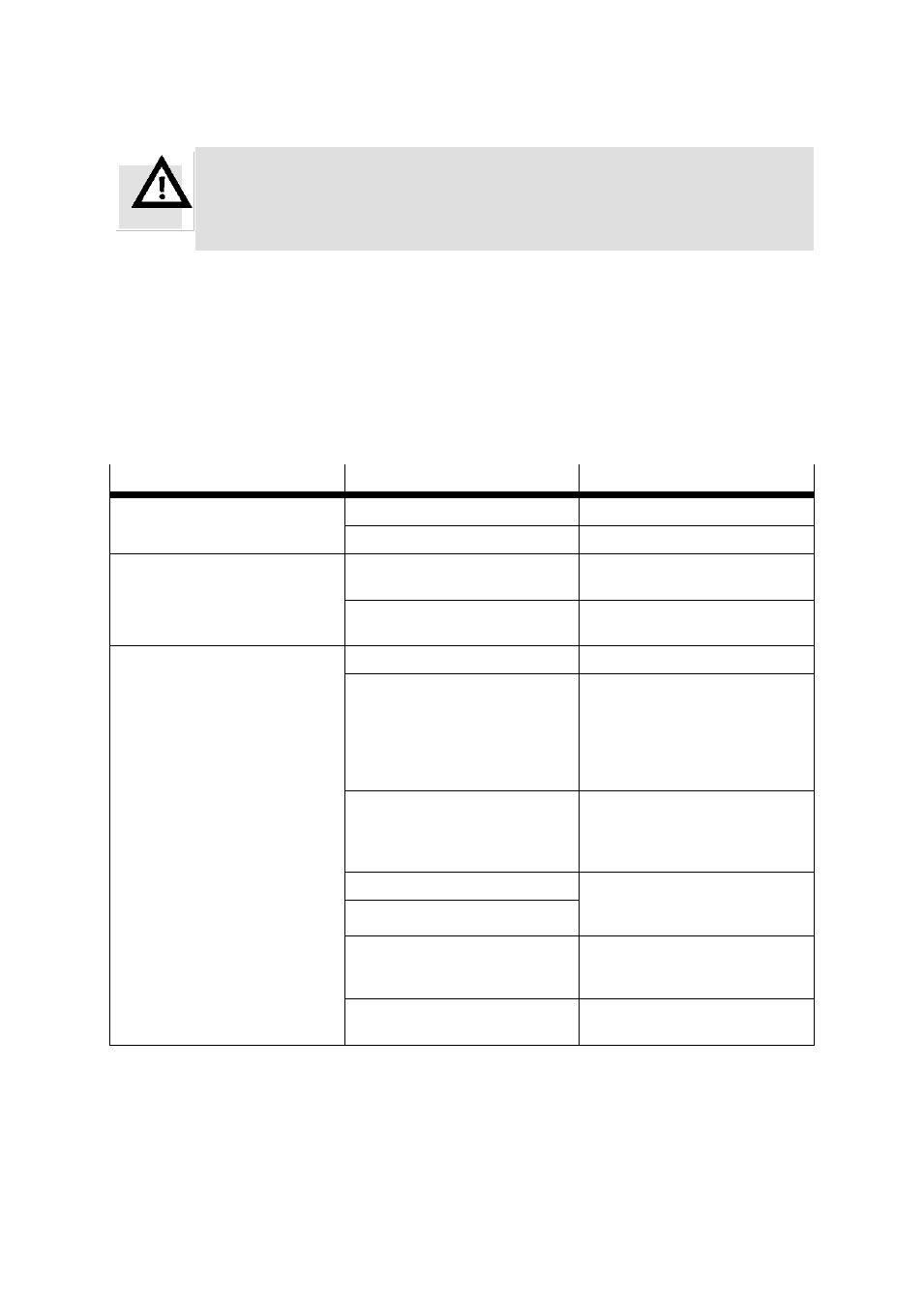

Fault

Possible cause

Remedy

Uneven movement of the slide

Bearing surfaces dirty

Clean the bearing surfaces

Vibration of the complete system Check mechanical structure

Faults in the reference travel

Ferritic parts in the vicinity of the

proximity switch

Use parts made of non-magnetic

materials

Incorrect parametrisation

Check parameters in the control-

ler

Squeaking noises or vibrations,

stiffness

Linear axis fitted distorted

Eliminate distortion

Natural vibration in the support

bearings due to resonance

Increase or reduce the mass, or, if

necessary, increase or reduce the

air pressure supply in the air

cushion bearing (if necessary,

please consult the Festo service

department)

Natural vibration in the side air-

cushion bearings

Change the prestressing in the air

cushion bearing (if necessary,

please consult the Festo service

department)

Effective load too large

Observe maximum values as per

diagram in chapter "Characte-

ristic curves"

Speed too high

Incorrect parametrisation

Check the parameters in the con-

troller by using the FCT paramet-

risation software

Temperature increase due to

loading in continuous operation

Repeat test run under continuous

operating conditions