Appendix fiafl - application example 71, Appendix “a” - application example – Red Lion TSC User Manual

Page 73

-71-

APPENDIX “A” - APPLICATION EXAMPLE

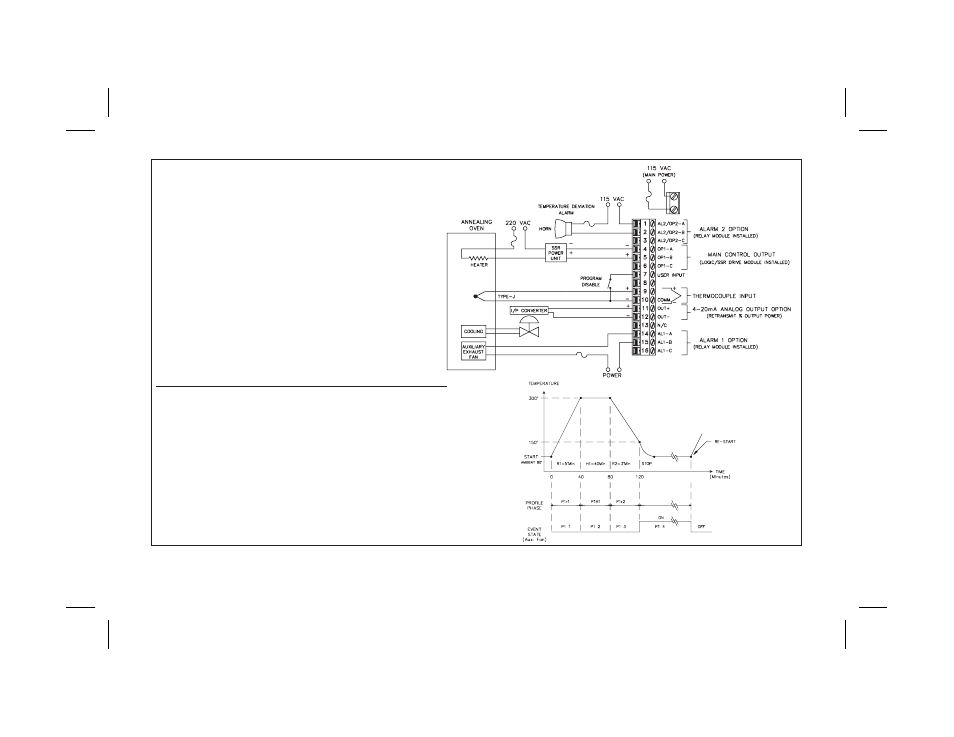

TSC Glass Tempering Application

A manufacturer of glass items needs to anneal (temper) their products to

reduce the brittleness of the glass structure. The tempering process

requires the glass to be heated and subsequently cooled at a controlled rate

to change the structure of the glass. Different tempering profiles are

required for different types of glass products.

A TSC is employed to control the temperature profile of the annealing

oven. Four different temperature profiles are stored in the controller. The

4-20 mA analog output option is utilized to cool the annealing oven during

the cool down ramp phases. An event output is used to quickly cool the oven

at the end of the batch run (alarm 1). Alarm 2 is used to signal the operator

whenever the temperature is outside the prescribed profile.

Note: Units equipped with the RS-485 option have different terminal

designators.See“OutputVariationswithorwithouttheRS-485Option”.

The programming for this profile is as follows:

Parameter

Value

Description

“P1r1”

5.0 Ramp from ambient temp. during heat phase at 5.0°/min.

“P1L1”

300 Target setpoint level 300°

“P1H1”

40.0 Heat at 300° for 40.0 minutes

“P1r2”

3.0 Ramp down 3.0°/min. during cooling phase

“P1L2”

150 Target Setpoint is 150°

“P1H2”

0.0 Do not hold at 150° (used as “phantom” hold time for

triggering event output for auxiliary cooling)

“P1r3”

-0.1 End Program

“P1 1”

1F2F Turn off output 1 (output 2 is alarm)

“P1 2”

1F2F Keep off output 1

“P1 3”

1F2F Keep off output 1

“P1 4”

1N2F Turn on output 1 for Auxiliary Exhaust Fan