Derivative time 65, Output power offset (manual reset) 65, Pid adjustments 65 – Red Lion TSC User Manual

Page 67

INTEGRAL TIME (Cont’d)

If integral action is disabled (Automatic Reset), manual reset is available by

modifying the output power offset (“OPOF” initially set to zero) to eliminate

steady state errors. This parameter appears in unprotected parameter mode

when integral time is set to zero. The controller has the feature to prevent

integral action when operating outside the proportional band. This prevents

“reset wind-up”.

Note: The Proportional band shift due to integral action may itself be “reset”

by temporarily setting the controller into the ON/OFF control mode

(proportional band =0).

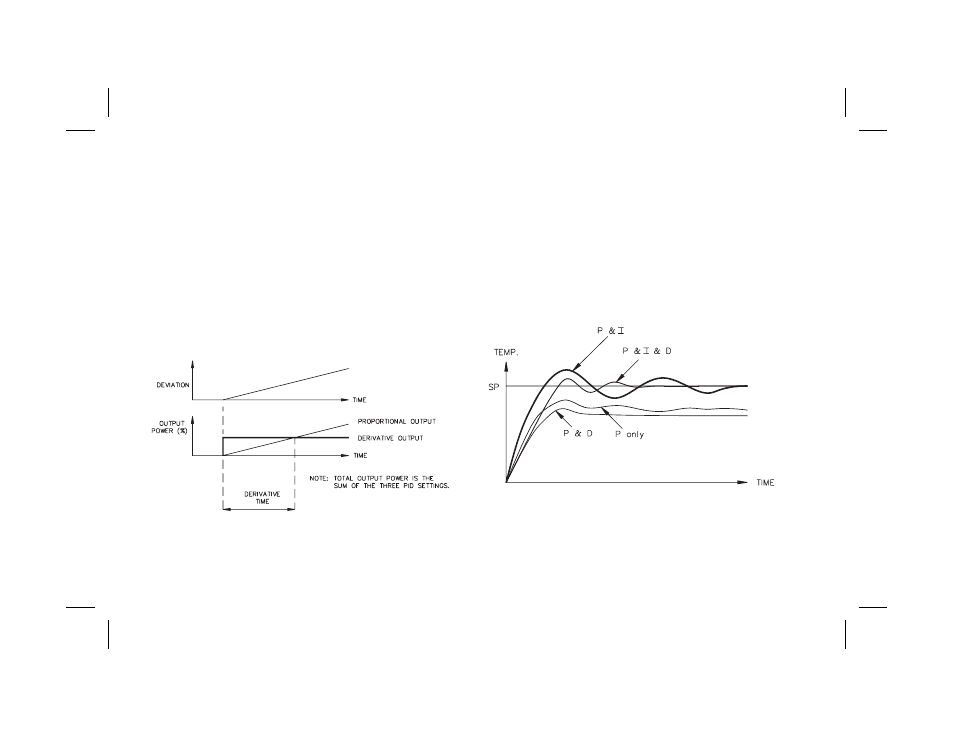

DERIVATIVE TIME

Derivative time is defined as the time, in seconds, in which the output due to

proportional action alone equals the output due to derivative action with a

ramping process error. As long as ramping error exists, the derivative action

will be “repeated” by proportional action every derivative time. The units of

derivative time are seconds per repeat.

Derivative action is used to shorten the process response time and helps to

stabilize the process by providing an output based on the rate of change of the

process. In effect, derivative action anticipates where the process is headed

and changes the output before it actually “arrives”. Increasing the derivative

time helps to stabilize the response, but too much derivative time coupled

with noisy signal processes, may cause the output to fluctuate too greatly

yielding poor control. None or too little derivative action usually results in

decreased stability with higher overshoots. No derivative action usually

requires a wider proportional and slower integral times to maintain the same

degree of stability as with derivative action. Derivative action is defeated by

setting the time to zero.

OUTPUT POWER OFFSET (MANUAL RESET)

If the integral time is set to 0 (automatic reset is off), it may be necessary to

modify the output power to eliminate errors in the steady state. The output

power offset (OPOF) parameter will appear in the unprotected mode, if the

integral time = 0. If integral action (automatic reset) is later invoked, the

previous output power offset remains in effect.

PID ADJUSTMENTS

To aid in the adjustment of the PID parameters for improved process

control, a temperature chart recorder is necessary to provide a visual means of

analyzing the process. Compare the actual process response to the PID

response figures with a step change to the process. Make changes to the PID

parameters in no more than 20% increments from the starting value and allow

the process sufficient time to stabilize before evaluating the effects of the new

parameter settings.

-65-