Setpoint limit values ( splo & sphi ) 30, Auto setpoint ramp rate ( sprp ) 30 – Red Lion TSC User Manual

Page 32

INPUT MODULE (1- IN) (Cont’d)

Input Sensor Correction Constants (SPAN & SHFt)

If the controller temperature disagrees with a reference temperature

instrument or if the temperature sensor has a known calibration, the controller

temperature can be compensated by a correction slope (SPAN) and offset

(SHFt).

SPAN - 0.001 to 9.999

SHFt - -999 to 9999

The following equation expresses the relationship:

Desired Display Temp = (Controller Temp x SPAN) + SHFt

EX1.) The controller reads 293°F while a reference instrument indicates

300°F. A SHFT value of +7°F corrects the controller indication to match

the reference. (Use SPAN = 1.000)

EX2.) A thermocouple probe is calibrated over the region of operation to

achieve more accurate temperature control. The calibration results are as

follows:

Desired Temperature

Thermocouple Output

400.0F

395.0F

800.0F

804.0F

SPAN = 800F - 400F = 0.978

804F - 395F

SHFT = 400F - (0.978 x 395F) = 13.7°F

SPAN value of 0.978 and SHFT value of 13.7°F corrects the indicator to

the probe.

Setpoint Limit Values (SPLO & SPHI)

The controller has programmable high and low setpoint limit values to restrict

the setting range of the setpoint. Set the limit values so that the temperature

setpoint value cannot be set outside the safe operating area of the process.

SPLO - -999 to 9999

SPHI - -999 to 9999

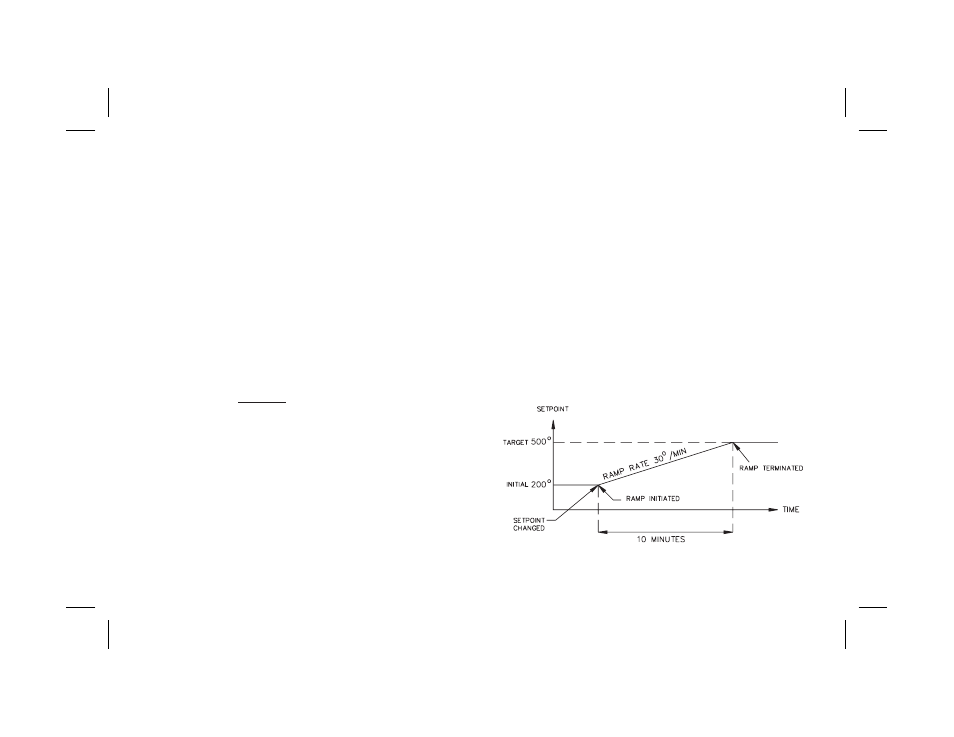

Auto Setpoint Ramp Rate (SPrP)

The setpoint can be programmed to ramp independent of the controller’s

display resolution. The setpoint ramp rate can reduce thermal shock to the

process, reduce temperature overshoot on start-up or setpoint changes, or

ramp the process at a controlled rate

SPrP - 0.1 to 999.9 degrees/minute

A ramp value of zero disables setpoint ramping. If the user input is

programmed for setpoint ramp, it affects the enabling and disabling of setpoint

ramping (refer to user input section). Setpoint ramping is initiated on

power-up or when the setpoint value is changed and is indicated by a decimal

point flashing in the far right corner of the main display.

Note: The auto setpoint ramp rate is independent from the operation of a profile.

Once the ramping setpoint reaches the target setpoint, the setpoint ramp rate

is disengaged until the setpoint is changed again. If the ramp value is changed

during ramping, the new ramp rate takes effect. If the setpoint is ramping prior

to invoking Auto-Tune, the ramping is suspended during auto-tune and then

resumed afterward using the current temperature as a starting value. Deviation

and band alarms are relative to the target setpoint, not the ramping setpoint. If

the analog output is programmed to transmit the setpoint value, the

instantaneous ramping setpoint value is transmitted.

Note: Depending on the ramp rate relative to the process dynamics, the actual

process temperature may not track the ramping setpoint value.

-30-