Pro file power cy cle sta tus ( pnst ) 44, Pro file er ror band ( pneb ) 44, Ramp phase ( pnrn ) 44 – Red Lion TSC User Manual

Page 46

Profile Power Cycle Status (PnSt)

Upon controller power-on, several profile operating modes exist. Each

profile has an independent power cycle status.

StOP - Stop places a profile into the Off mode, regardless of the mode

prior to power down.

CONt - Continue resumes the operation of a running profile (including

event output states) at the point where power was removed

to the controller.

Strt - Start automatically re-starts a profile. This is useful for

automatic execution, soft-start profile at power-up,

or automatic execution of a standard profile.

Power cycle status may be changed while a profile is running. The options

of the power cycle status may create conflicts between one or more profiles.

The priority structure for the power cycle status is:

Priority #1 - The profile that was running and programmed for continue

resumes operation when power is restored.

Priority #2 - If the profile that was running prior to power down is

not programmed for continue, any profile programmed

for start will re-start. Profile 1 has the highest priority.

Profile Error Band (PnEb)

Profile temperature conformity can be assured by using the profile Error

Band parameter. If the process temperature deviates outside the error band

value while a profile is running, the controller enters the delay mode. In the

delay mode, the time base of the profile is held (delayed) until the process

temperature is within the deviation error band. At this time, the profile

continues running unless the process temperature again deviates. These

actions assure that the actual process temperature conforms to the profile. The

error band can be programmed for a positive or negative value which is

expressed in degrees.

PnEb - -999 to 9999 degrees

A Positive Error Band value operates on hold phases only. This is useful

when temperature soak time must be assured without affecting ramp phase

time. A Negative Error Band value allows a profile to enter the delay mode on

both ramp AND hold phases. This parameter may be altered during profile

operation and the new values takes effect immediately. A value of 0 disables

Error Band detection.

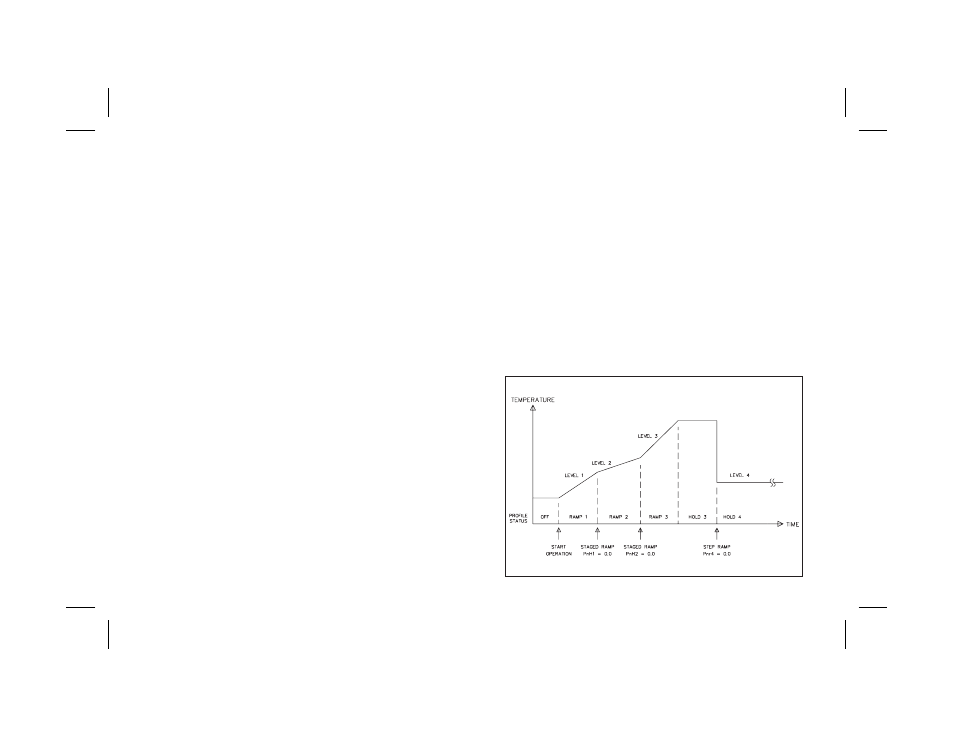

Ramp Phase (Pnrn)

The ramp phase is defined as automatic changing (ramping) of the setpoint

value over a discrete time period at a predefined rate. The ramp rate is

expressed in tenths of degree per minute.

Pnrn - 0.1 to 999.9 degrees/minute

The slope of the ramp phase (up or down) is automatically determined by

the controller using the current setpoint value and target setpoint value. Upon

starting a profile, the setpoint value begins ramping from the measured input

temperature value to the target setpoint value. A profile can begin ramping

from a defined setpoint level by entering 0.0 for the first ramp phase and 0.0

for the first hold phase. Entering 0.0 causes the profile to advance directly to

the target setpoint value and begin the hold phase. This is known as a Step

Ramp Phase. Timed Event outputs update at a Step Ramp Phase. The next

ramp phase starts after the hold phase times-out.

A “staged” ramp approach is possible by using hold phase times of 0.0

minutes and redefining the new ramp rate(s).

-44-

STAGED RAMP & STEP RAMP PROFILE