Pf3000 pro cotton yield monitor, Ag leader technology – Ag Leader PF3000Pro Cotton Yield Monitor Operators Manual User Manual

Page 139

PF3000 Pro Cotton Yield Monitor

Ag Leader Technology

Troubleshooting

July 2003

6-5

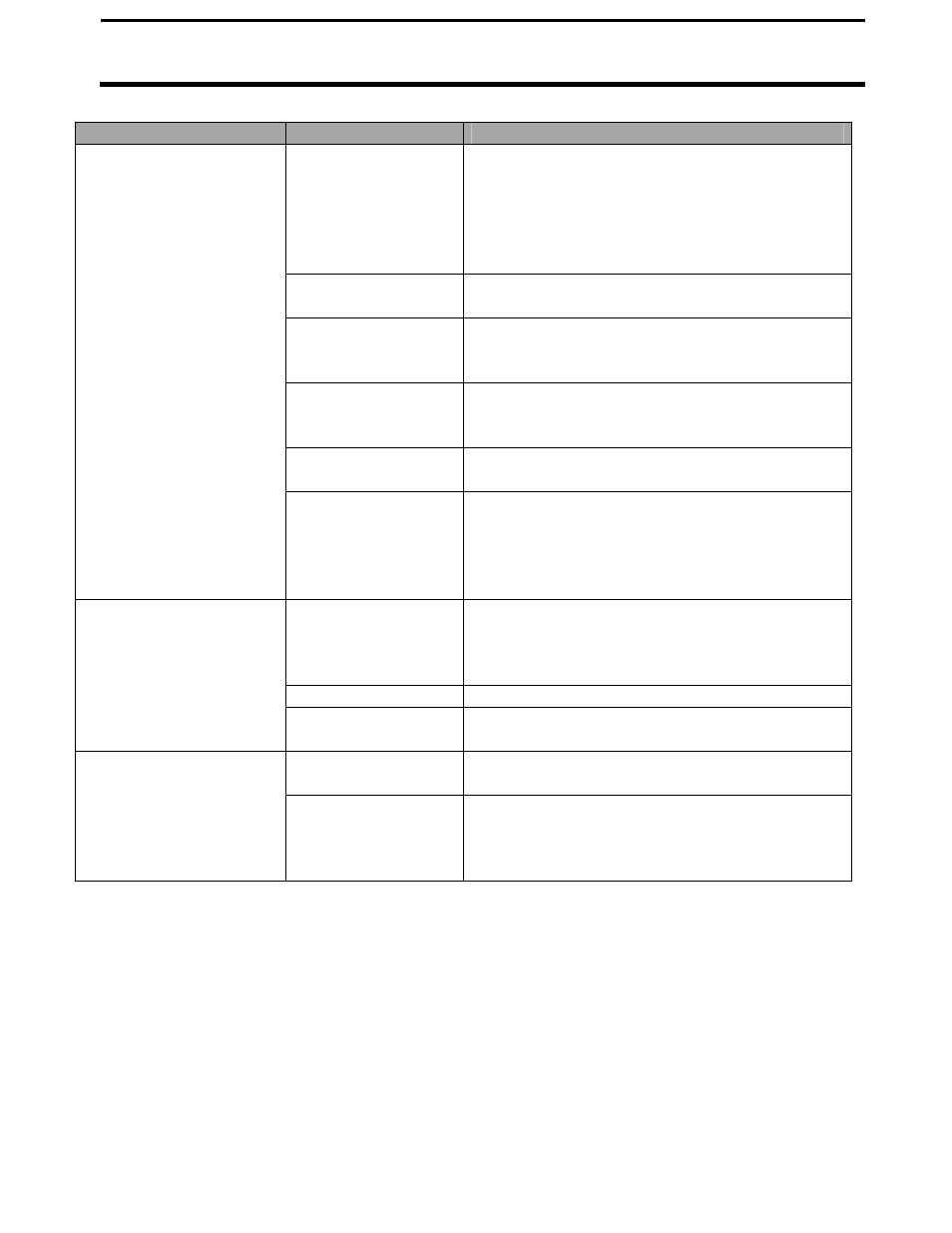

Problem

Cause

Solution

Incorrect Cotton Weight

(lbs) (cont)

Stringers

Remove sensor and check for ANY cotton that

could interfere with the sensors. Check around

the lens covers for small pieces of trash or lint that

can interfere with proper sensing. File or smooth

any sharp edges below the sensor that may cause

cotton to catch.

Lens covers

excessively dirty

Refer to "Poor Signal Strength" in this section.

Calibration numbers

C1, C2, C3 are set

incorrectly

Refer to "Weight accumulated when stopped"

section.

Sun light on sensors

Check the chute for any holes that could allow

sunlight to directly shine or reflect into the

detector. Fill with RTV (silicone)

Sensor out of

alignment

Refer to "Poor Signal Strength" in this section.

The result of

changing field

conditions.

Create a new calibration variety.

Weigh and enter one or two calibration loads for

different field conditions.

Fan Speed is Zero or

Erratic. NOTE: Fan

speed must be above 2500

to record cotton.

Fan clutch not

engaged.

Engage fan clutch.

Bad connection

Check cable connections

Speed sensor out of

adjustment

Adjust sensor to be as close as possible to the

sensed gear.

Magnetic speed

sensor bad

Replace magnetic speed sensor.

Monitor set on wrong

fan pulses per

revolution.

Press MENU, SETUP and VEHICLE. Fan

Pulses/Revolution appears at top of display. Refer

to initial calibration sheet, then press EDIT and

use up/down arrow keys to set pulses correctly.