Fig. 12.7 – LumaSense Technologies INNOVA 1314i User Manual

Page 147

Chapter 12

______________________________________________________________________

_____________________________________________________________________________

BE6030-13

1314i Photoacoustic Gas Monitor

LumaSense Technologies A/S

Page 147 of 199

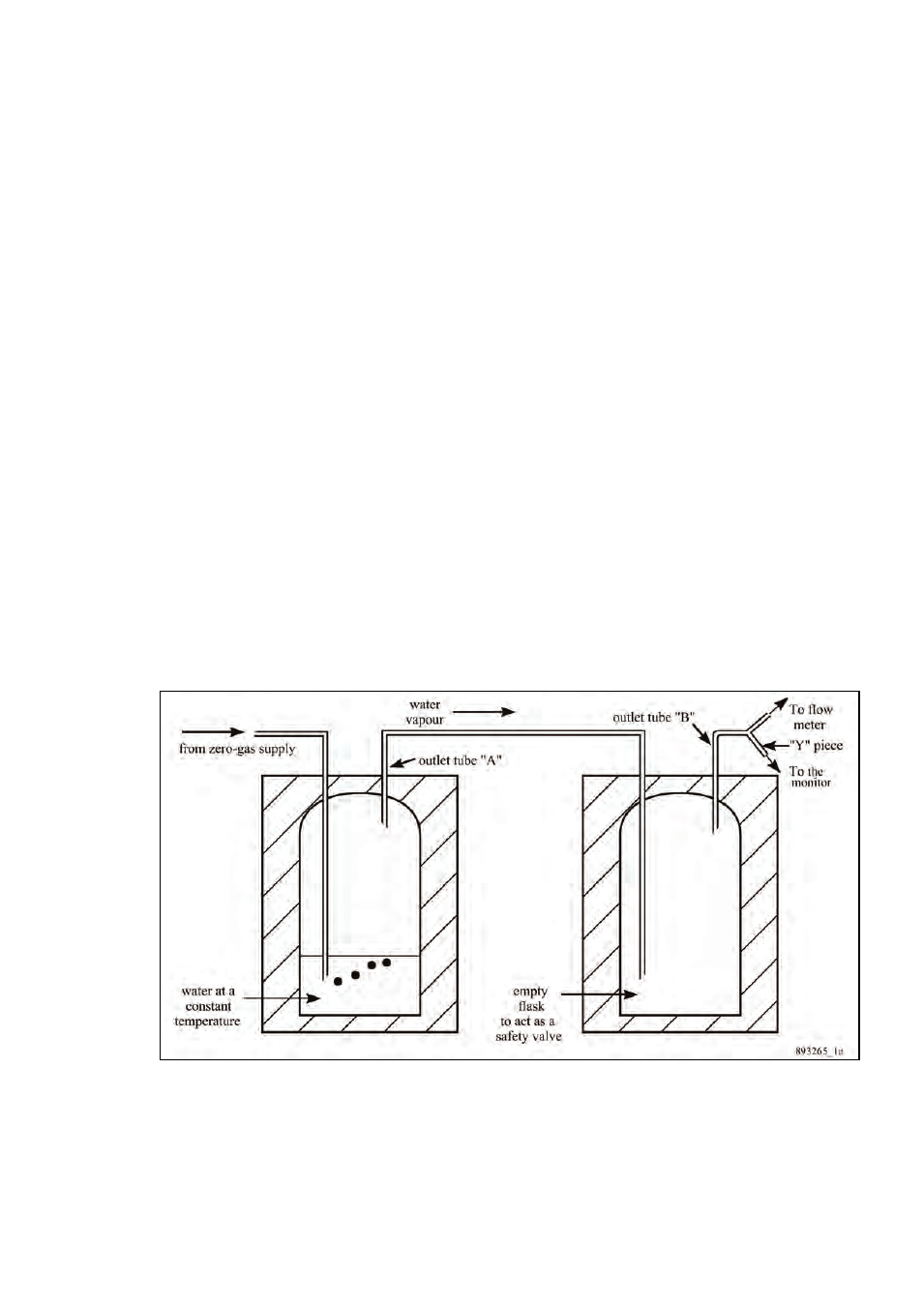

water bath is linked up to an extra “empty” flask. This is to prevent a

situation where the level of water in the controlled water-bath rises

and covers the outlet tube “A” and draws water, via the “Y”-piece,

directly into the Monitor’s analysis cell. Water will seriously damage

the cell. To avoid such a situation, we suggest that the wet air from

the water-bath outlet tube is fed into an extra empty flask before

being fed to the air-inlet of the Monitor. Note the length of the

respective tubes in the flasks. It is vitally important that any

water, which collects in the extra flask, does not cover the short

outlet tube “B”.

It is very important that the concentration of water vapour used is

below the saturated water-vapour pressure of the air in the room

where calibration is being performed; otherwise water vapour will

condense out in the analysis cell. In practical terms this means that:

·

The Monitor must have time to reach the ambient temperature of

the room before a calibration task is performed.

·

The temperature of the water bath you use should be at least 2°C

below the ambient temperature of the room where calibration is

to be performed. So, if your ambient temperature is 20°C, make

sure that the temperature of the water-bath you use is set at a

maximum of 18°C.

Fig.12.7 Schematic diagram of the equipment necessary to produce

a supply of clean, wet air.