IAI America ACON-SE User Manual

Page 110

100

6. T

roubleshooting

6.4 Messages Displayed during Operation Using the Teaching Pendant or PC

Software

This section explains the warning messages that may be displayed during operation using the teaching pendant

or PC software.

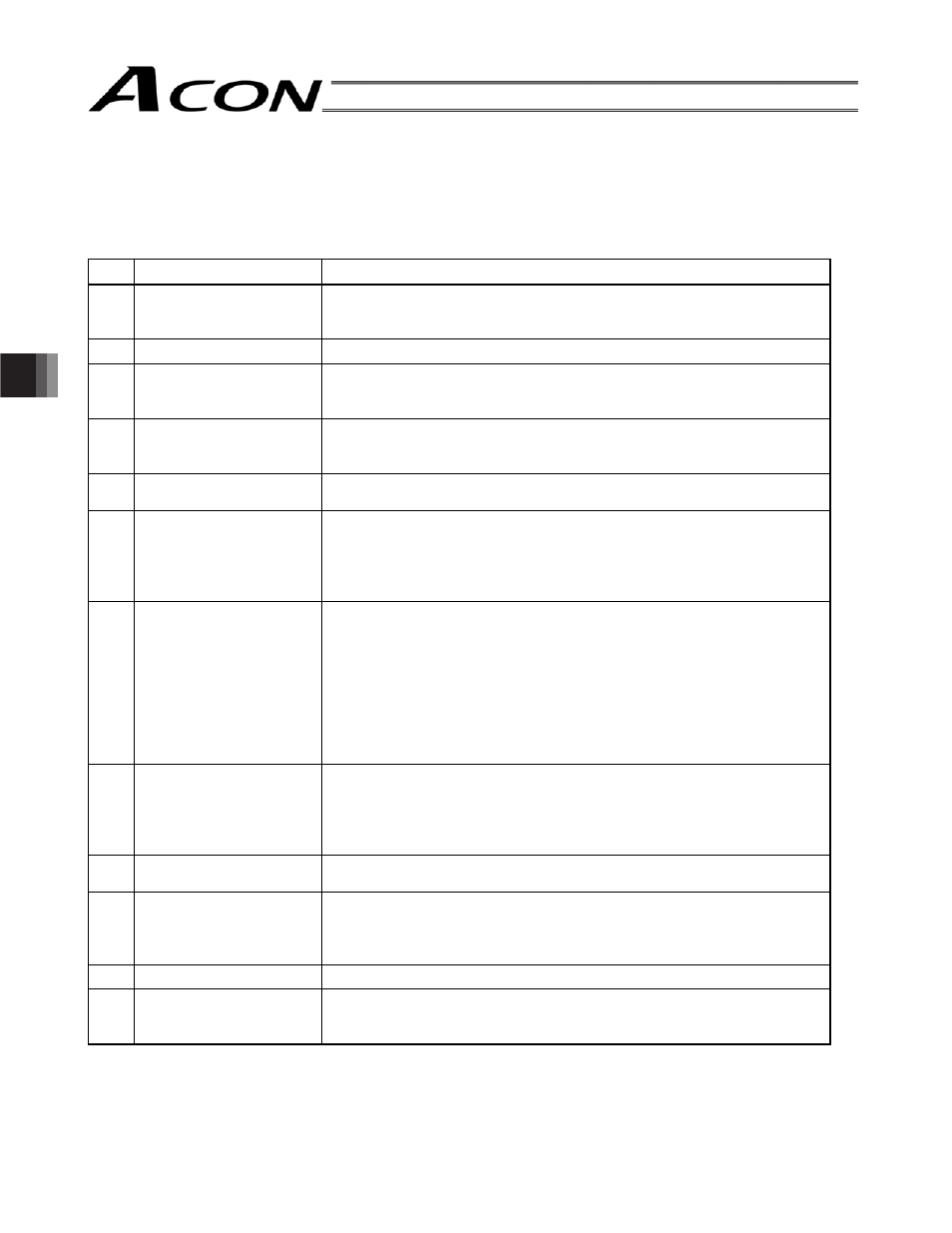

Code Message

name

Cause/Action

112 Invalid data

An inappropriate value was entered in a parameter.

(Example) 9601 was entered as the serial communication speed by

mistake. Reenter an appropriate value.

113 Value too small

The entered value is smaller than the setting range.

114 Value too large

The entered value is larger than the setting range.

Refer to the actuator specifications or parameter table and reenter an

appropriate value.

115 Home

return

non-completion

The current position was written when home return was not yet

completed.

Execute home return again.

117 No movement data

Target position is not set under the selected position number.

Enter the target position first.

11E Paired data mismatch

The values indicating the magnitude relationship of a pair of data are

inappropriate.

(Example) The same value was entered in both the parameters for +

DQG±VRIWOLPLWV

Reenter appropriate values.

11F Absolute position too

small

The minimum movement toward the target position is determined by the

lead length of the drive system and resolution of the encoder.

This message indicates that the entered target value is smaller than the

minimum movement.

([DPSOH ,IWKHOHDGOHQJWKLVPPWKHHQFRGHU¶VUHVROXWLRQLV

pulses and accordingly the minimum movement becomes 20

y PPSXOVH

In this case, this message will be displayed if 0.02 mm is

entered as the target position.

121 Push & hold search end

over

The final position in push & hold operation exceeds the soft limit.

This has no negative effect if the actuator contacts the work. If the

actuator misses the work, however, the soft limit will be reached and this

message is displayed as a warning.

Change either the target position or positioning band.

122 Multiple

axes

connected

at assignment

Address was assigned when multiple axes were connected.

Assign each address only when one axis is connected.

Address change OK

Controller initialization OK

Home change all clear

I/O function changed

These messages are displayed to confirm operation.

(They do not indicate an operation error or other abnormality.)

202 Emergency stop

An emergency stop condition was detected. (This is not an error.)

20A Servo OFF during

operation

This message indicates that the servo ON signal (SON) was turned OFF

by the PLC while the actuator was moving, and that the servo turned

OFF and the movement was disabled as a result.