Flow rate control - critical flow orifices – Teledyne 9110TH - Nitrogen Oxides Analyzer User Manual

Page 285

Troubleshooting & Repair

Model 9110TH NOx Analyzer

Teledyne Analytical Instruments

265

8.3.2.1. NO/NO

x

and AutoZero cycles

For the routing of the sample gas flow, the analyzer uses a variety of valves. The

NO/NO

X

valve directs the sample gas either directly to the reaction cell or through the

unit’s NO

2

converter, alternating every ~4 s. The AutoZero valve directs the sample gas

stream to completely bypass the reaction cell for dark noise measurement once every

minute, which is then subtracted as a measurement offset from the raw concentration

signal. The valve cycle phases are summarized in the following table.

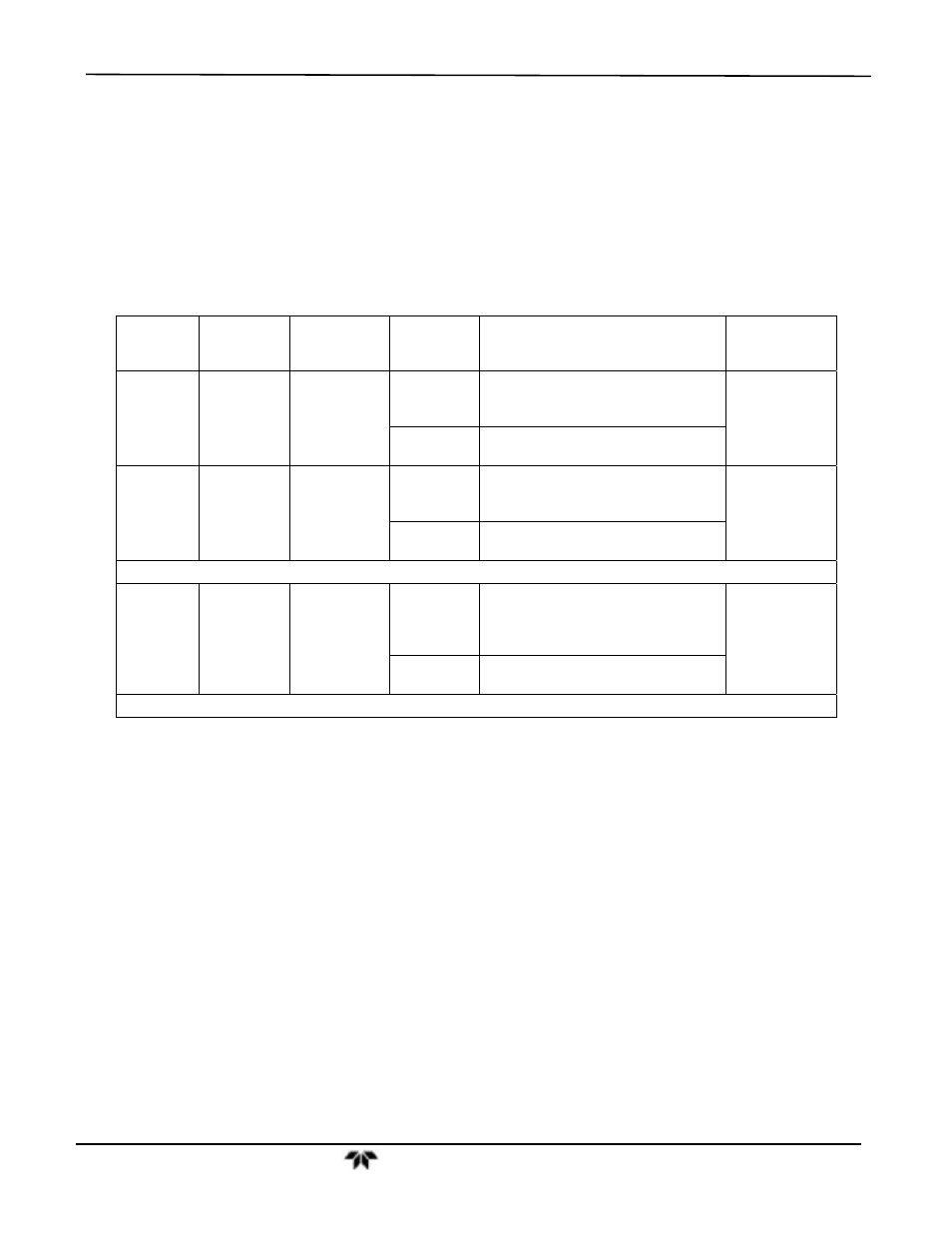

Table 8-2: 9110TH/M Valve Cycle Phases

PHASE

NO/ NO

X

VALVE

STATUS

AUTOZERO

VALVE

STATUS

TIME

INDEX

ACTIVITY FIGURE

NO

Measure

Open to

AutoZero

valve

Open to

reaction cell

0 - 2 s

Wait period (NO dwell time).

Ensures reaction cell has been

flushed of previous gas.

Figure 8-2

2 - 4 s

Analyzer measures chemilumi-

nescence in reaction cell.

NOX

Measure

Open to

NO

2

converter

Open to

reaction cell

4 – 6 s

Wait period (NOX dwell time).

Ensures reaction cell has been

flushed of previous gas.

Figure 8-2

6 – 8 s

Analyzer measures NO + O3 chemi-

luminescence in reaction cell.

Cycle repeats every ~8 seconds

AutoZero

Open to

AutoZero

valve

Open to

vacuum

manifold

0 – 4 s

Wait period (AZERO dwell time).

Ensures reaction cell has been

flushed of sample gas and chemi-

luminescence reaction is stopped.

Figure 8-4

4 - 6 s

Analyzer measures background

noise without sample gas

Cycle repeats every minute

8.3.3. FLOW RATE CONTROL - CRITICAL FLOW ORIFICES

The Model 9110TH/M analyzers use special flow control assemblies (Figure 8-8)

located at various locations within the instrument to maintain constant flow rates for

both the O

3

supply air and the sample gas. These assemblies consists of:

A critical flow orifice.

Two o-rings: Located just before and after the critical flow orifice, the o-

rings seal the gap between the walls of assembly housing and the critical

flow orifice.

A spring: Applies mechanical force needed to form the seal between the o-

rings, the critical flow orifice and the assembly housing.

The figures that follow highlight the location of these flow control assemblies: