GF Signet 4632 Chlorine Dioxide Analyzer System User Manual

Page 37

37

463X Chlorine System Manual

Appendix

Storage periods greater than 2 months:

•

If the sensor has been in storage for a long period of

time, or used in a chlorine free environment, the sensor

may develop a low slope (output), which may cause the

sensor to have a slow response time.

•

In this case, the sensor must be reconditioned.

Required to recondition a sensor:

• DI Water

• Beaker (any size available)

• Polishing Sheets (Included in sensor maintenance kit)

• Free Chlorine: Chlorine Bleach (13% concentration)

• Chlorine Dioxide: Aqueous Chlorine Dioxide solution

Reconditioning Procedure:

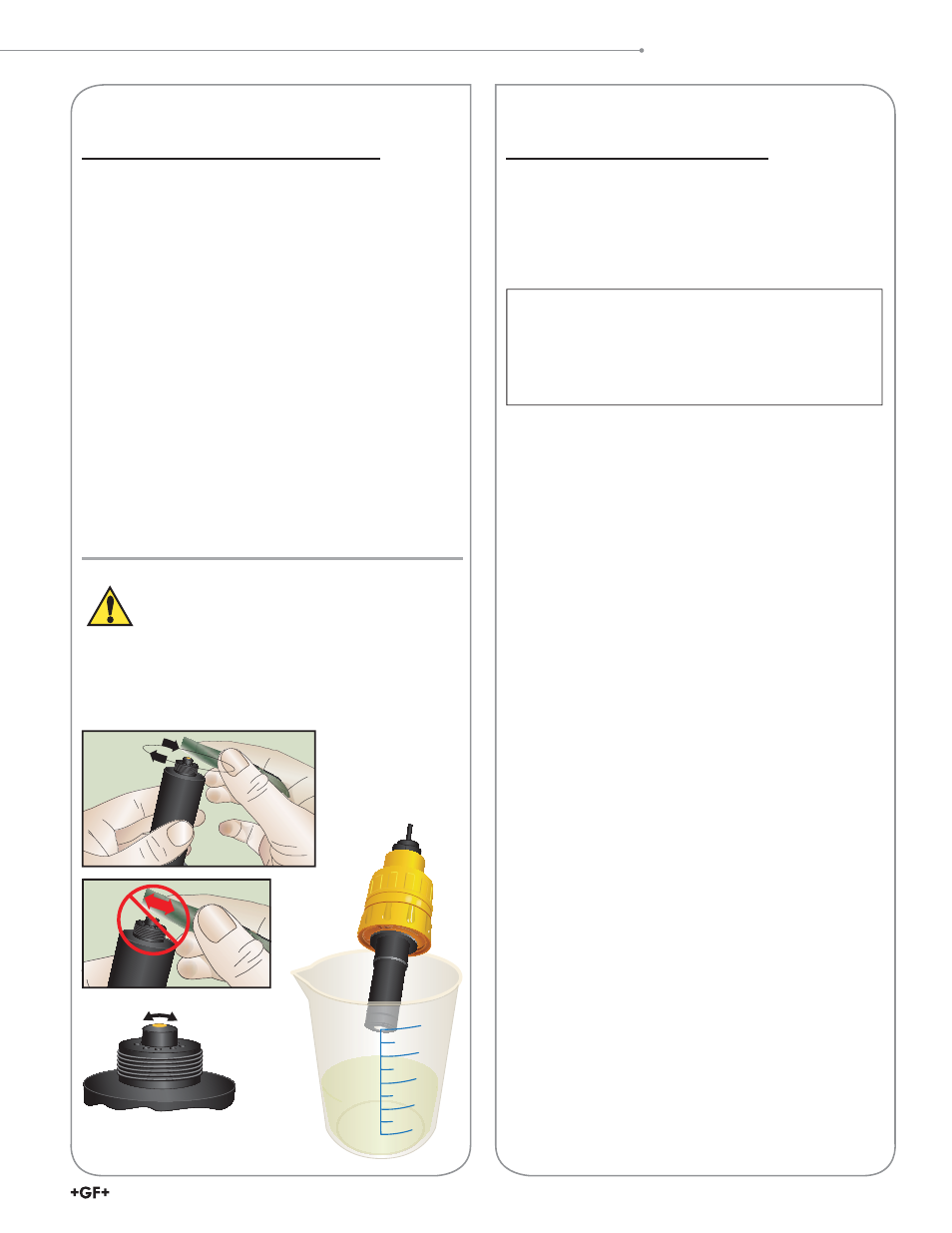

1. Remove the sensor from the 2750-7 electronics.

2. Remove the membrane cap.

3. Place the sensor on a ¿ rm À at surface with the gold

cathode pointing upward.

4. Apply a small amount of water to the Blue (Course)

polishing paper (dull side).

5. Polish the gold electrode by moving the paper in a

circular pattern for 30 seconds. DO NOT go back and

forth in a single direction. See Figure 1.

6. Rinse the sensor tip with DI water.

7. Apply a small amount of DI water to the White

(Fine) polishing paper (dull side) and polish the gold

electrode by moving the paper in a circular pattern for

30 seconds. DO NOT go back and forth in a single

direction. See ¿ gure 1.

8. Rinse the sensor tip with DI water.

9. Top off the sensor with electrolyte and inspect

membrane for dirt or damage. Replace if necessary.

10. Insert the sensor into the 2650 electronics and

apply power.

11. Fill beaker with a 12 mm (½ inch) of the appropriate solution.

12. Position or suspend the sensor 0.2 mm to 12 mm

(¼ in. to ½ in.) above the appropriate solution.

See Figure 2. DO NOT SUBMERGE THE SENSOR.

13. Apply power to the system.

14. Monitor the nA of the sensor (press the down arrow

once on the 8630 transmitter). The nA reading should

start to rise. Response time and nA reading will depend

upon the temperature of the appropriate solution.

15. Once the sensor's nA reading reaches approximately

300-360 nA allow the sensor to remain in the beaker,

suspended over the appropriate solution, for an

additional 20 minutes.

• If sensor does not recover quickly, cover the

beaker to avoid air contamination.

•

Contact the factory for assistance (www.gfsignet.com).

16. After 20 minutes, remove the sensor and install it into

the À ow cell and restore À ow to the system.

17. Calibrate the sensor after the system has become stable.

CAUTION!

Bleach and Chlorine Dioxide solutions are very

corrosive and may release dangerous gases if it

comes in contact with acids.

• Wear proper protective clothing (gloves and eye protection)

• Avoid contact with skin and eyes

• Observe all warnings on safety data sheets

• Avoid spilling bleach and possible contact with acids

Figure 2

Figure 1

Curved Surface

Greater than 1 week, but less than 2 months:

•

Remove the membrane cap and internal electrolyte

solution.

•

Rinse the sensor internal chamber with DI water or cold

tap water; drain and allow to dry.

•

Place the membrane cap back onto the sensor. INSTALL

LOOSE, DO NOT COMPLETELY TIGHTEN THE CAP.

WHEN STORED DRY, THE MEMBRANE CAP MUST BE

STORED RELAXED AND UNSTRESSED.

•

Store sensor DRY in the shipping bottle,

DO NOT ADD WATER.

Recommissioning Procedure:

1. Fill the sensor with the electrolyte as outlined in

Maintenance, Page 36, and install the membrane cap.

2. The sensor will have to be polarized in the À ow cell with

À owing Chlorinated water before being used.

Note: This may take 30 to 120 minutes before calibration

can be performed.

3. If the sensor does not recover after recommission, follow

steps 1-10 outlined under

Storage periods greater than 2 months.

4. If the sensor still fails to work properly,

continue with steps 11-17.

Storage Periods: