GF Signet 4632 Chlorine Dioxide Analyzer System User Manual

Page 11

11

463X Chlorine System Manual

Sensor Preparation

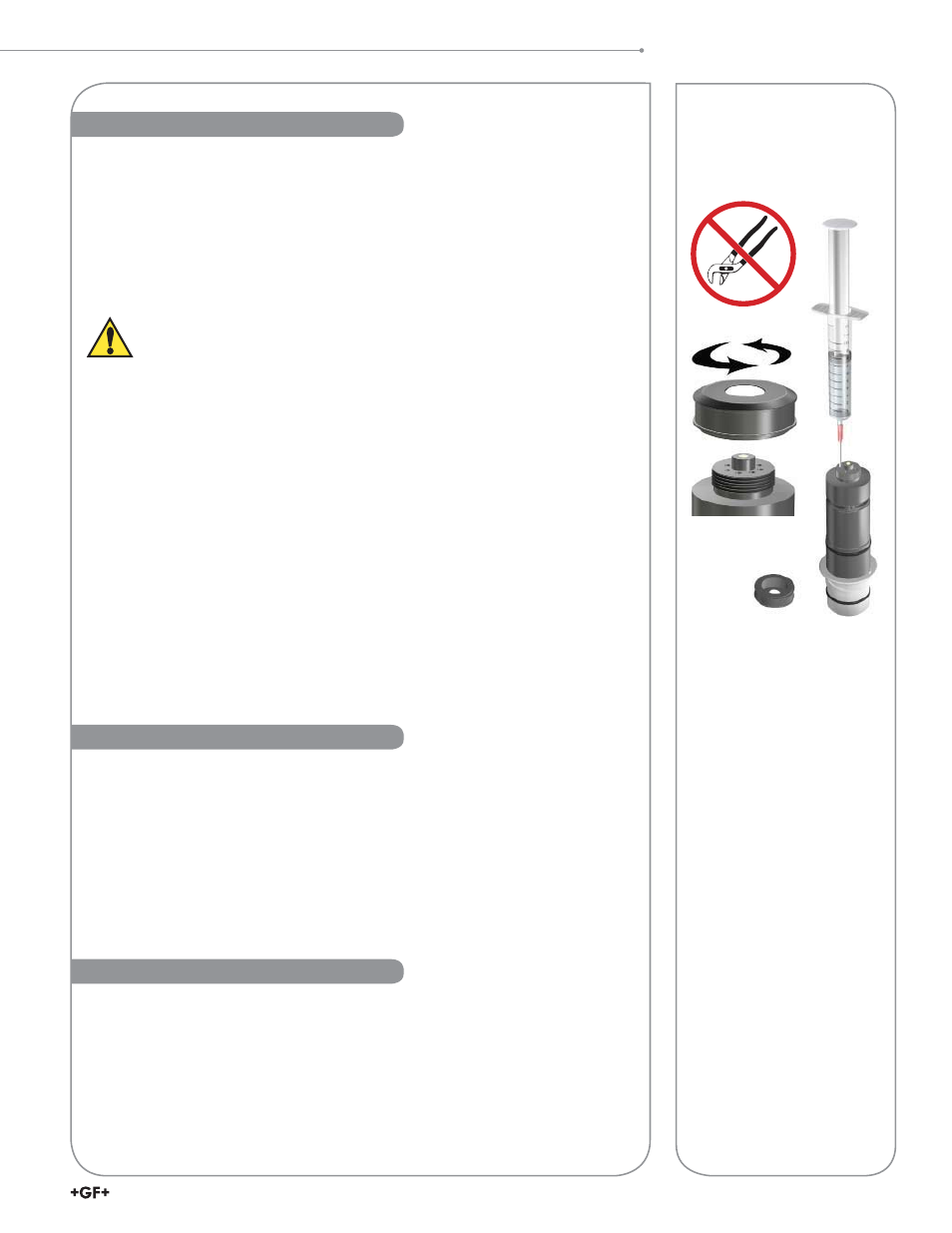

Avoid skin or eye contact with electrolyte solution.

Wear rubber gloves and goggles.

* Material Safety Data Sheets (MSDS) are available online at www.gfsignet.com.

Initial Fill Procedure:

When adding electrolyte, be prepared for an accidental spill.

Working near a sink is recommended.

1. Remove the protective bottle from the end of the electrode

2. Remove the membrane cap from the front of the sensor.

Note: When new sensors are shipped, the membrane cap is not tightened to the sensor

3. Fill supplied syringe with electrolyte solution.

Additional caution should be taken when handling Chlorine Dioxide electrolyte solution.

4. Place the electrode on a level surface.

5. Insert syringe needle fully into one of the eight electrode holes while injecting with

electrolyte solution. Slowly injecting the electrolyte solution into the sensor to avoid

introducing air bubbles. The electrode holds approximately 14 milliliters of solution.

Slowly ¿ ll until solution begins to À ow out of holes. Do not allow the solution to run

down the electrode and wet the electrical contacts in the DryLoc connector.

6. Slowly screw on the membrane cap ¿ nger tight. Do not use tools. To avoid damage

and contamination, do not touch the white membrane surface on the membrane cap.

• Chlorine sensors are shipped without internal electrolyte solution.

• Prior to installation and supplying power, Chlorine sensors must be ¿ lled with the

appropriate internal electrolyte solution.

• Verify the correct electrolyte solution is utilized with the corresponding sensor.

• Free Chlorine and Chlorine Dioxide sensor require different electrolyte solutions.

2630 Free Chlorine Electrode

2632 Chlorine Dioxide Electrode

NOTE: Inspect and change the

membrane cap if damaged.

See page 36, Maintenance, for

cleaning procedure.

A new chlorine electrode or one that has had the membrane cap changed must be

calibrated. See page 24, 8630 Transmitter information on calibration of the chlorine

sensor. A diethyl-p-phenylenediamine (DPD) colorimeter test kit (not included) is required

for sensor calibration. A sample is taken and analyzed with the DPD test kit, then this

value is entered into the Signet 8630 transmitter.

• Calibrate after a membrane cap change (requires 4 hour stabilization time).

• Calibrate after the internal electrolyte is replaced (requires 2 hour stabilization time).

• Check calibration one day after sensor is placed in service.

• Check calibration weekly to monthly depending on process requirements.

The sensor membrane and internal electrolyte solution must be replaced over the life

of the electrode. To maintain accurate chlorine measurements, GF Signet recommends

that the internal electrolyte be replaced every 3 to 6 months, or when Chlorine readings

drift low and/or cannot maintain a calibration longer than 5 days. Actual interval between

maintenance of the sensor will be dependent on the actual applications, chlorine level and

contaminates in the water. See Appendix page 36; Maintenance and Storage.

Keep spare membrane caps available. Membrane caps carry no warranty.

Chlorine Sensor Calibration

Chlorine Sensor Preparation

Chlorine Sensor Maintenance

CAUTION:

DO NOT touch the gold tip or

the membrane of the sensor.