Control box – standard (fe petro stp), Interface schematic to ts-lld - 12, Reference schematic – Franklin Fueling Systems TS-LLD Installation Manual User Manual

Page 46: Figures 2.3 - 11 & -12, Page 2.3 - 12 ts-lld installation guide

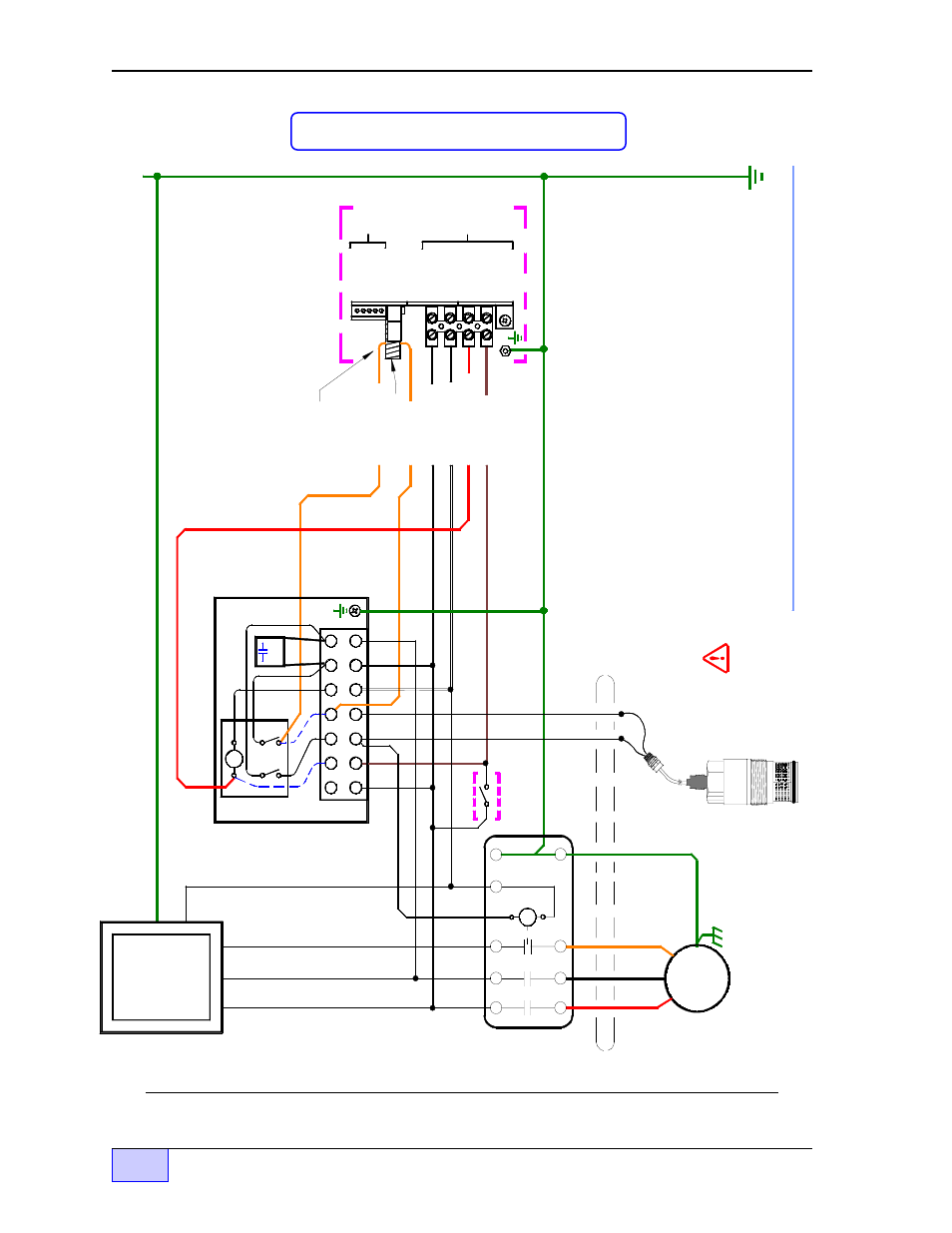

Figure 2.3-11 Three Phase 240 VAC Supply – Starter – and Motor Control Box

Standard Interface Schematic to TS-LLD

Install Line Filter Cap at L1 and L2

DANGER ELECTRICAL SHOCK HAZARDS. TURN OFF AND LOCK-OUT THE SUBMERSIBLE PUMP POWER SOURCE (L1, L2, L3 - AT THE CIRCUIT BREAKER) - BEFORE - WORKING ON THIS EQUIPMENT. FAILURE TO TURN OFF THE THREE PHASE POWER SOURCE WILL RESULT IN SEVERE INJURY OR DEATH.

Conduit to pump Junction Box

N

STP 3 phase Motor

...OverLoads

( OLs )

are in series with M1and M3

RED

BLK

ORG

Three Phase Motor Control Panel Starter ...see NOTES 1 and 2

T2

T1

T3

L1

L2

L3

TS-LLD LSU (Leak Sensing Unit) at IST Pump Housing Leak Detection Port

BLK

GND

GND

Dispense Switches

GND

L2

L1

L3

N

Electrical Power Panel

P/N

020-0028

S2

N (N o t e 1)

S1

M1

M2

NL

2

L1

Aux. Control Relay Box (remove dashed wires)

2 NEU

Neutral (WHT)

INCON TS-LLD & FE PETRO Three Phase STP Wirin

g Dia

gra

m

1) If the motor starter coil is 230 VAC then do not wire to neutral -- wire to M1.

2) Observe color code L1 L2 L3 phase sequence for proper rotation of motor.

3) All conduit fittin

gs, EYS seal fittin

gs, and junction boxes in

manholes or other Hazardous areas are to be explosionproof rated for: Class 1, Div 1, Group D and wet locations

NOTES

RLY COIL (RED)

S2 (BRN) Pump On Sig. (source = L1)

GND

TB1

4 P-IN

SIG RTN

3 P-OUT

TS-LLD Control Unit (CU)

Power Source = L1

No connection. Wire is routed through the donut-shaped Pickup Coil

Pickup Coil

L1 Line (BLK)

RLY N.O. (ORG)

M1 (ORG)

TB2

2 485B 3 DSY1

F1

4 DSY2 5 ALARM

1 110V

1 485A

GND