Franklin Fueling Systems TS-LLD Installation Manual User Manual

Page 20

DANGER

Fire, Explosion, & Electrical Shock Hazard. Before installing,

servicing, or working on this equipment, make sure

all submersible pump power

and pump relay coil / dispenser

power is turned off & locked out at the electrical

panel.

Prevent automatic or unauthorized pump start-ups, spills from pressurized

lines, and electrical shocks.

See Chapter 2.1 follow all Safety advise.

2)

Relieve pipe line pressure. Reference the detailed instructions found in the

submersible pump manufacturers’ documentation about relieving pressure in the

pipe line.

WARNING

The pipe line is under pressure –

relieve line pressure. If the

line leak detector / plug is removed before the pipe line pressure is relieved, then a

product leak will occur ! A explosion, fire, or environmental hazard may be created.

3)

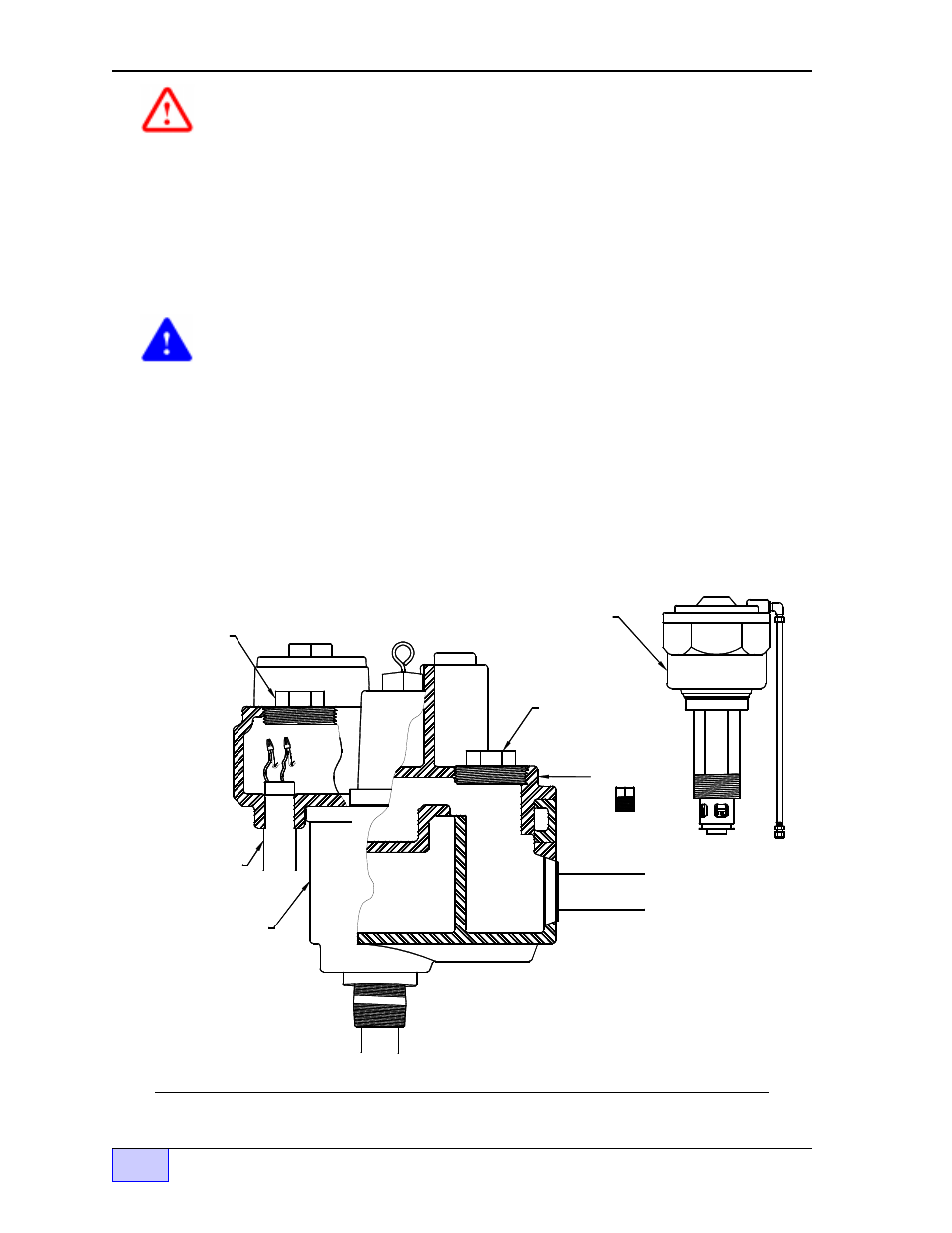

Remove the 2 or 3 inch junction box plug and the 2 inch line leak plug, or

mechanical line leak detector (if present), from the pump housing per

Figure 2.2-2

or

2.2-3. Use petroleum absorbent / absorbing rags to collect and contain spills if

they occur (be sure to properly dispose of these afterwards). If a mechanical line

leak detector was removed, then apply pipe dope on the threads of the

supplied 1/4 NPT hole plug, and install this plug into the tank test port.

Figure 2.2-2 Plug Location – RedJacket

PUMP HOUSING

STATION

CONDUIT

1/4" PLUG

PIPELINE

MECHANICAL

LINE LEAK

DETECTOR

2" PLUG

2" PLUG