Note 2.3, Note - 4 – Franklin Fueling Systems TS-LLD Installation Manual User Manual

Page 38

Control Unit Installation Steps (continued...

)

5) Wiring at the Pump Control Relay Box:

a) Remove the wire from S2 to the relay coil

b) Remove the wire from M2 to the relay N.O. contact

c) Install the 1µ Farad “Line Filter” capacitor (INCON P/N 020-0028) between

terminals L1 and L2

d) Wire the CU to the pump relay box as described below TABLE 2.3-1 and as

shown in

Figures 2.3-4 & 2.3-5. Strip 1/4 inch of insulation off each end (for

termination at the control unit and for the spade crimp connectors at the pump

relay box). Use connectors sized for 14 AWG wire.

Other pump relay boxes may have different terminations, and/or may

be wired differently than what is shown in this manual.

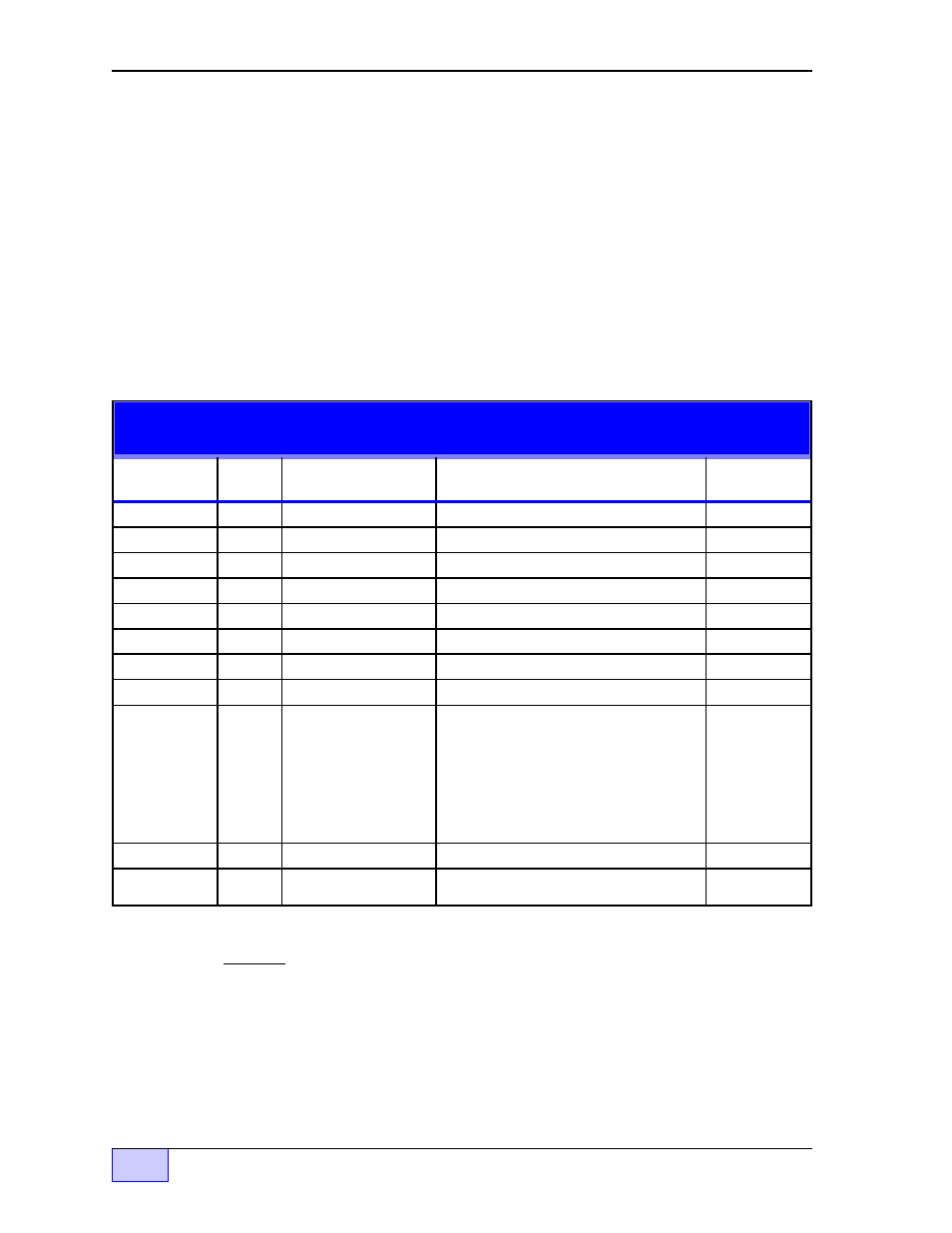

Typical Single Phase Wire Connection List TABLE 2.3 -1

PUMP RELAY BOX — to — TS-LLD CONTROL UNIT ( CU )

P-OUT (Pump On - output signal,

{ Pump Motor Power - the 14 gauge

orange wire is pre-routed through the

pick-up coil at the Control Unit.

relay box, wire one end to the M2

terminal, & wire the other end to the

pump relay N.O. contact (Figure 2.3-

4)... no wiring/connection at CU

Electricians:

All AC wiring at the control unit (TB1-1 110V and TB1-4 P-IN)

must be in-phase and read 0 VAC in respect to each other and must read

from 110 to 130 VAC in respect to ground. Reference Figures 2.3-4 thru

2.3-10. These are “typical” diagrams and may not represent the actual wiring.

A

0 VAC potential must exist from TB1-1 to the hot side of dispenser on switch S1

( or to

S2 ) with the dispense switch on. Take voltage readings at the pump relay

box. Use the leg that is in-phase with

S1 ( L1 or L2 that reads 0 VAC) and wire it

to

TB1-1 ( 110V ).

For 3 phase applications —

DO NOT use any leg that

reads more than 130 VAC to Ground !

NOTE

☞

NOTE

☞