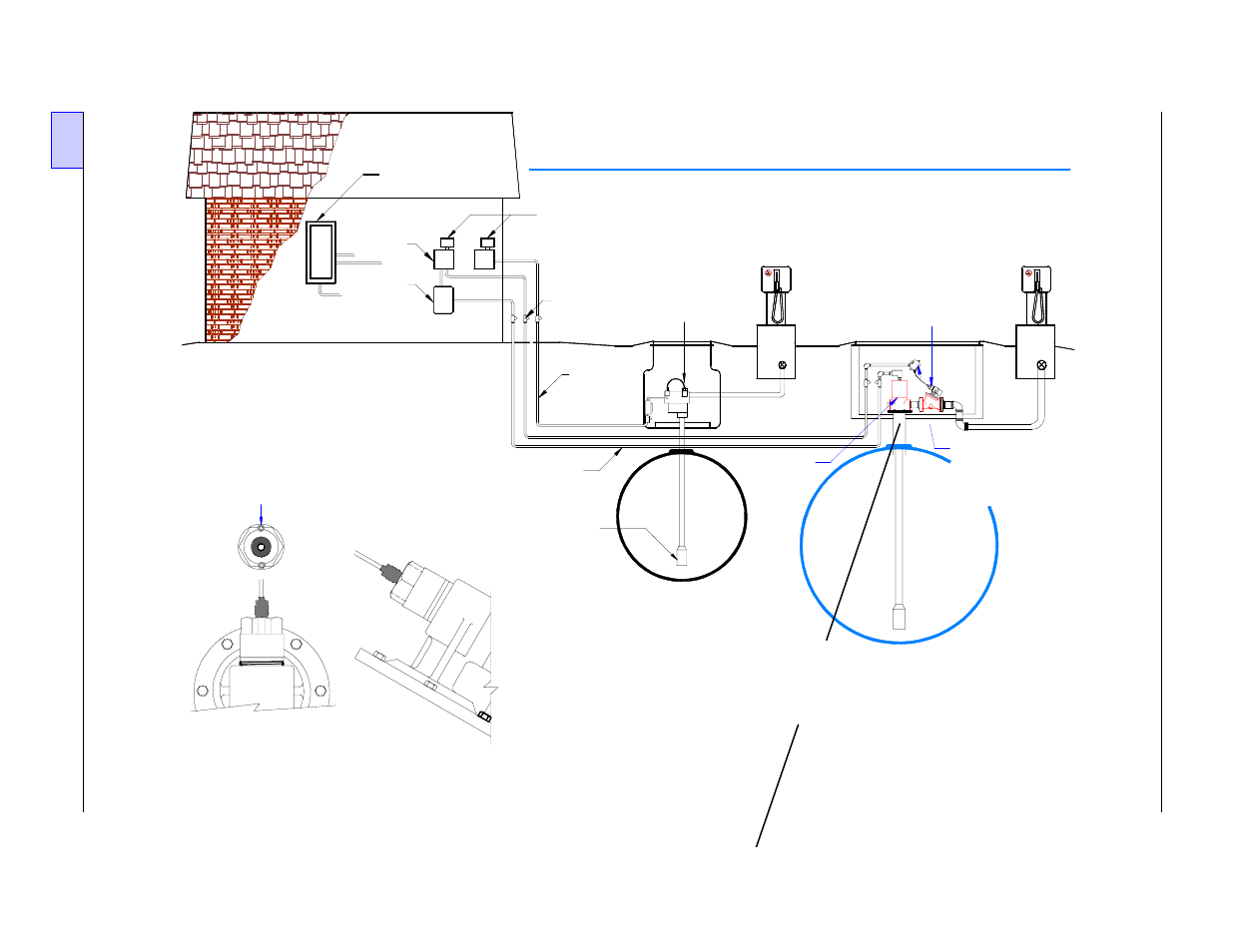

Figure 2.2-15 incon ts-lld installation at bigflo, Diaphragm valve -14 & 2.2 - 15 – Franklin Fueling Systems TS-LLD Installation Manual User Manual

Page 32

INCON TS-LLD Line Leak Detector

BigFlo & Diaphragm Valve Installation

Tank - Pump # 1

("Standard" Single Phase

Installation)

TS-LLD LSU (#1)

(Leak Sensing Unit)

at pump housing

Standard Single

Phase Installation

NOTE:

1)

2)

An additional Single Phase 230 VAC

Relay Control Box (panel), two additional

wires, and possibly an additional conduit run to

the LSU, are required for 3 Phase Applications.

The INCON TS-LLD LSU MUST be installed

so the fasteners are aligned in a 12 & 6 o'clock

(vertical) position as shown in Detail A - A.

Tighten the LSU to meet this requirement.

Detail A - A

Overhead Top View

(correct alignment)

Partial

Enlarged

Side View

Submerged

Turbine

Pump (STP)

Existing

Conduit

(Pump 2)

Electrical

Power Panel

Pump

Relay

Boxes

3 Phase

Pump

Motor

Starter

TS-LLD CUs

(Control Units):

# 2 and # 1

2

1

2

Epoxy

Filled

EYS

Seal

Fittings

Existing

Conduit

(Pump 1)

Tank - Pump # 2

(BigFlo Three Phase Pump and

Diaphragm Valve Installation)

BigFlo Pump

Note:

Use two

conduits

when

conduit

fill exceeds

40% full as

specified

by your

National

Electric

Code.

Explosion-

proof

Junction

Box . . . . .

TS-LLD LSU (#2)

(Leak Sensing Unit)

at Diaphragm Valve

see Detail A - A

Dispenser

# A

BigFlo

STP

Pump

Dispensers

# B thru # X