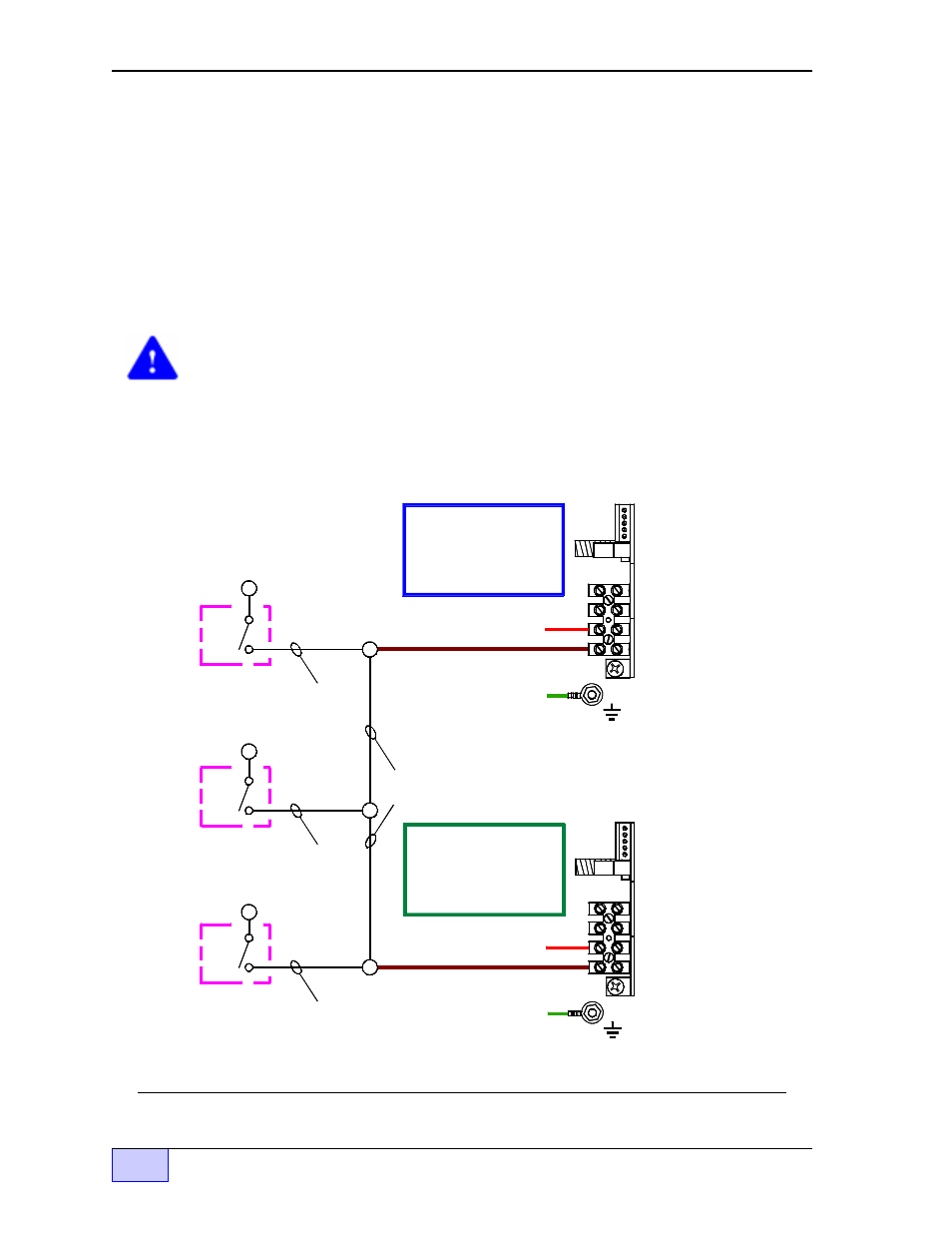

Figure 2.3-7 mechanical blender dispensers to, Ts-lld control unit interface schematic - 8, Ts-lld line leak detector – Franklin Fueling Systems TS-LLD Installation Manual User Manual

Page 42: Mechanical blender interface, Dispense on

TS-LLD Line Leak Detector

—

Mechanical Blender Interface

When connecting a TS-LLD line leak detector to systems with mechanical

blenders, tie the: premium, all mid-grades, and regular dispenser switch signals

together (electric blenders can be wired normally). Wire both premium and

regular TS-LLD Control Units at TB1-4 (P-IN). See the typical (partial) wiring

diagram below. Because the mid-grades are blended mixtures of the premium

and regular octanes, any product dispense will abort leak tests at the premium

and regular Control Units.

CAUTION The

dispense on

signals must be

in phase

to avoid electrical shorts

and damage. Verify that all dispenser switch signals are in phase before you tie

them together (in phase = 0 Volts AC in respect to each other and 120 Volts AC in

respect to Neutral or ground). Note that both pumps will be active on any

dispense.

PREMIUM

TS-LLD

Control Unit

REGULAR

TS-LLD

Control Unit

TO: REGULAR MOTOR

START RELAY COIL

TO: PREMIUM MOTOR

START RELAY COIL

REGULAR

Dispense

Switch (es)

MID-GRADE

Dispense

Switch (es)

S1

N.O.

C

N.O.

C

Dispense

(on) signal

Dispense

(on) signal

Tie

together

PREMIUM

Dispense

Switch (es)

S1

N.O.

C

S1

Dispense

(on) signal

2 NEU

SIG RTN

1 110V

1 485A

2 485B

3 DSY1

4 DSY2

5 ALARM

TB1 -

F1

TB2 -

1 110V

1 485A

2 485B

3 DSY1

4 DSY2

5 ALARM

2 NEU

SIG RTN

TB1 -

TB2 -

F1

Figure 2.3-7 Blended Dispensers to TS-LLD Control Unit – Interface Schematic