R&M Materials Handling HOIST MONITORS User Manual

Page 79

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

79/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

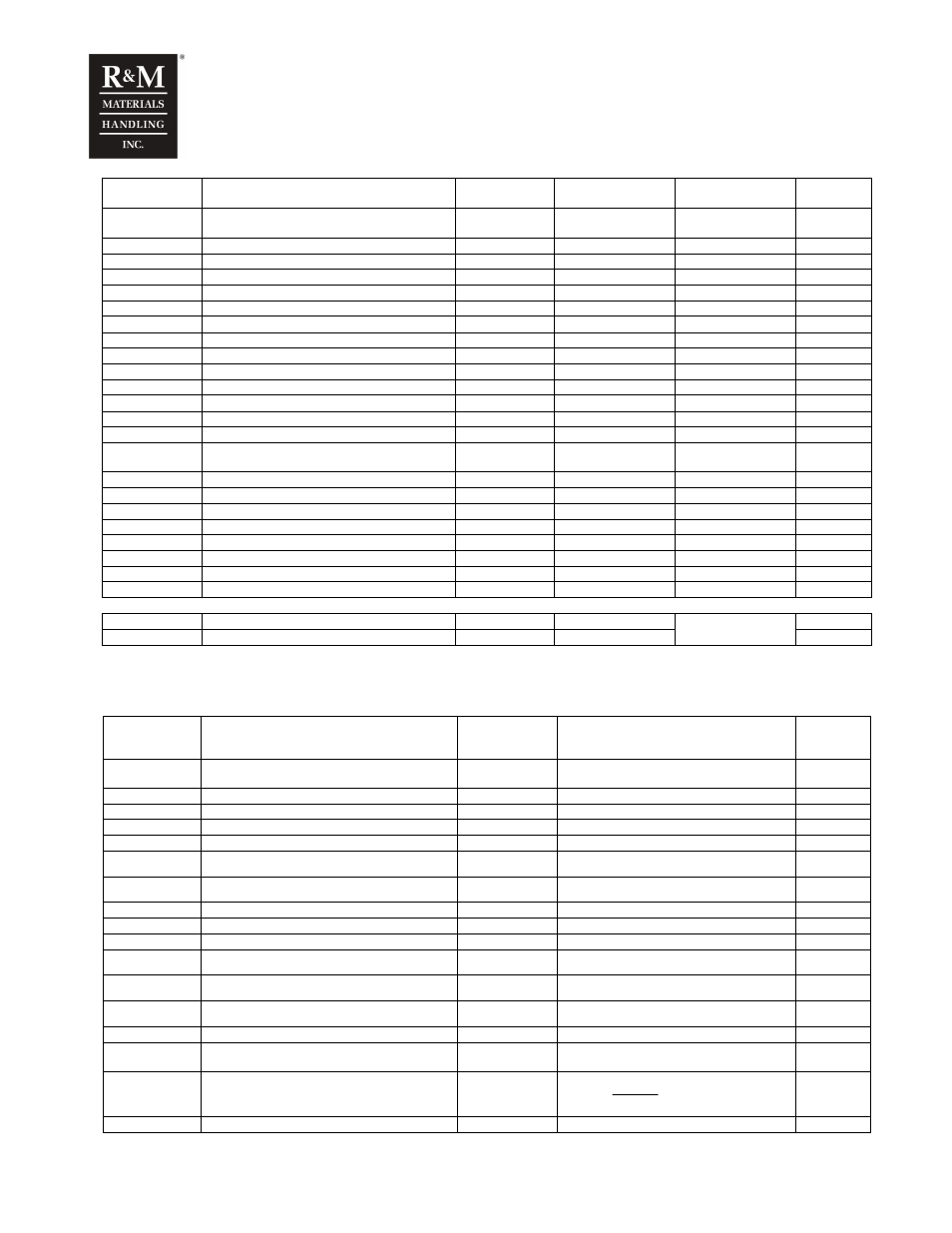

Read old values

from old unit

Description

Last recording

Value []

Estimated increase

since last record

Copy value to

Set Value

1-1-4 Cycles

Counter how often a load bigger than 20% of

hoist nominal load was lifted

7-1 Cycles

1-1-7 MFI1 RT

Run time in hours from Multi Function Input 1

7-2 MFI1 RT

1-1-8 MFI1 ST

Start counter from Multi Function Input 1

7-3 MFI1 ST

1-1-9 MFI2 RT

Run time in hours from Multi Function Input 2

7-4 MFI2 RT

1-1-10 MFI2 ST

Start counter from Multi Function Input 2

7-5 MFI2 ST

2-2 RT slow

Hoist run time in hours with slow speed.

7-6 RT slow

2-3 RT fast

Hoist run time in hours with slow speed

7-7 RT fast

2-4 No. OT

Counter for hoisting motor over temperatures

7-8 No. OT

2-5 No OL

Counter value for overload situations

7-9 No OL

2-6 E-stops

Counter for emergency stops

7-10 E-stops

2-7 ST up

Counter value for UP requests

7-11 ST up

2-8 ST down

Counter value for DOWN requests

7-12 ST down

2-9 ST fast

Counter value for FAST requests

7-13 ST fast

2-10 Max ED

Max value of calculated ED percentage

7-14 Max ED

2-11 Over ED

Minutes when the ED value has exceeded the

designed values.

7-15 Over ED

2-13 SRT3

Calculated value from Load and Run time, ^ 3

7-16 SRT3

2-14 SRT8

Calculated value from Load and Run time, ^8

7-17 SRT8

2-16 SL1

Calculated value from Load and Cycles, ^1

7-18 SL1

2-17 SL3

Calculated value from Load and Cycles, ^3

7-19 SL3

2-18 SL8

Calculated value from Load and Cycles, ^8

7-20 SL8

2-19 Power on

Total hours when the unit was powered on.

7-21 Power on

must be 0

2-20 Temp index Power on time weighted with unit’s temperature.

7-22 Temp index

must be 0

2-21 Max Load

The highest measured load.

7-23 Max Load

6-18 Max Br

Max designed brake operations.

1-1-6 Br SWP%

Counter of Stops and E-Stops

7-24 Brake operation

counter

If only Monitor 1-Condition monitoring menu’s values are read, some parameter values are possible

to calculate to menu 7.

Description

Read old values

from old unit

Set value

Desing

values from

parameter

7-1 Cycles

Counter how often a load bigger then 30% of

hoist nominal load was lifted

1-1-4 Cycles

Set the parameter’s 1-1-4 Cycles value

7-2 MFI1 RT

Run time in hours from Multi Function Input 1

1-1-7 MFI1 RT

Set the parameter’s 1-1-7 MFI1 RT value

7-3 MFI1 ST

Start counter from Multi Function Input 1

1-1-8 MFI1 ST

Set the parameter’s 1-1-8 MFI1 ST value

7-4 MFI2 RT

Run time in hours from Multi Function Input 2

1-1-9 MFI2 RT

Set the parameter’s 1-1-9 MFI2 RT value

7-5 MFI2 ST

Start counter from Multi Function Input 2

1-1-10 MFI2 ST

Set the parameter’s 1-1-10 MFI2 ST value

7-6 RT slow

Hoist run time in hours with slow speed.

1-1-3 Run time

25

,

0

*

_

_

time

Run

slow

RT

=

7-7 RT fast

Hoist run time in hours with slow speed

1-1-3 Run time

75

,

0

*

_

_

time

Run

fast

RT

=

7-8 No. OT

Counter for hoisting motor over temperatures

Set to 0

7-9 No OL

Counter value for overload situations

Set to 0

7-10 E-stops

Counter for emergency stops

Set to 0

7-11 ST up

Counter value for UP requests

1-1-2 Starts

5

,

0

*

_

Starts

up

ST

=

7-12 ST down

Counter value for DOWN requests

1-1-2 Starts

5

,

0

*

_

Starts

down

ST

=

7-13 ST fast

Counter value for FAST requests

1-1-2 Starts

75

,

0

*

_

Starts

fast

ST

=

7-14 Max ED

Max value of calculated ED percentage

Set to 0

7-15 Over ED

Minutes when the ED value has exceeded the

designed values.

Set to 0

7-16 SRT3

Calculated value from Load and Run time, ^ 3

1-1-1 SWP%

3

_

*

%

100

%

3

SRT

D

SWP

SRT =

6-10

D_SRT3

7-17 SRT8

Calculated value from Load and Run time, ^8

Set to 0