4 parameters – R&M Materials Handling HOIST MONITORS User Manual

Page 18

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

18/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

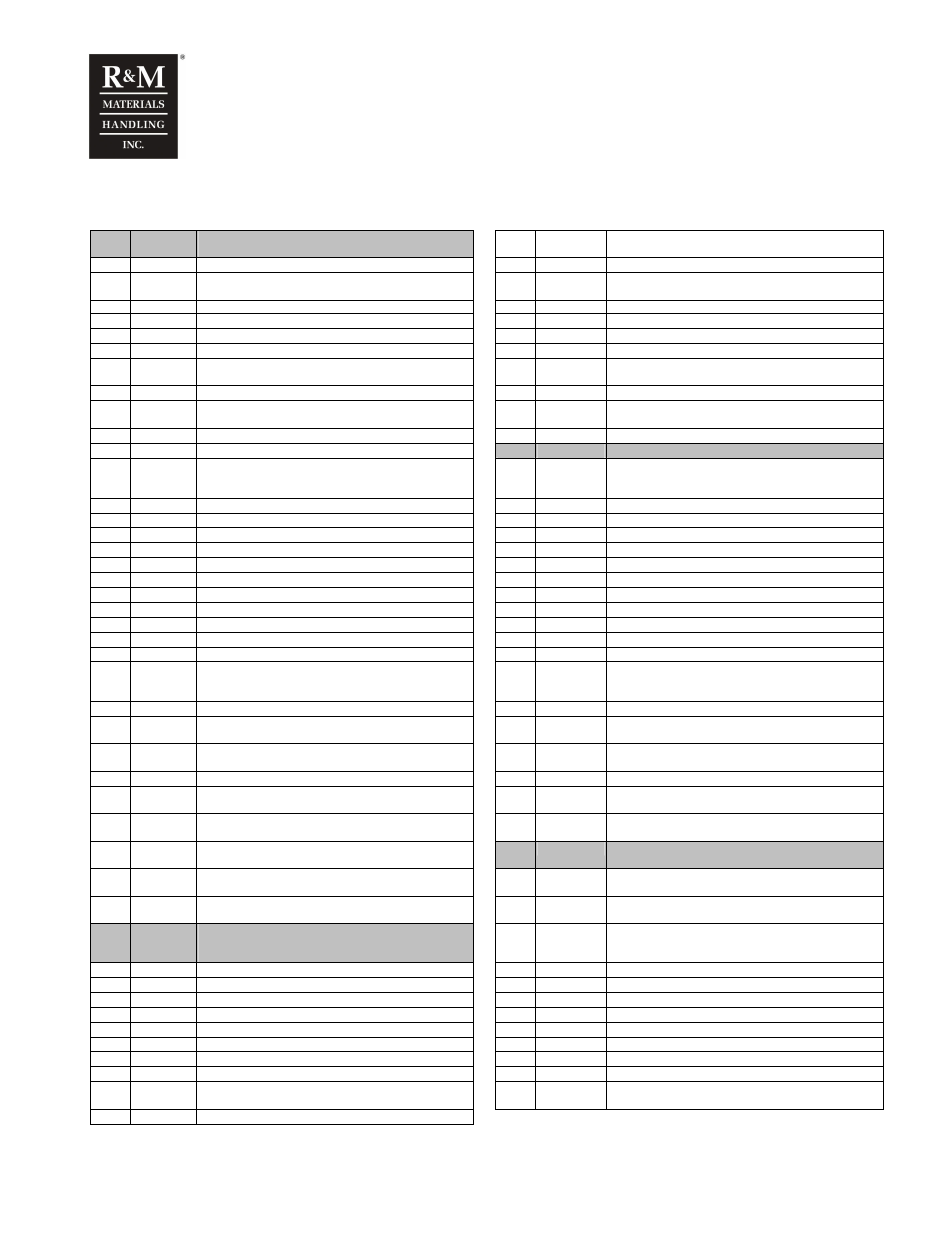

4 Parameters

1

Monitor 1

Read only menu for condition monitoring values and

measured values.

2-11

Over ED

Counts the minutes when ED value has exceed the

nominal ED value

1-1

Cond mon Condition monitoring menu

2-12

SWPRT%

SWP% value calculated with hoist running time

1-1-1

SWP%

Remaining Safe Working Period of the hoist in

percentage, starting from 100%.

2-13

SRT3

Load sum with hoist running time, third power

1-1-2

Starts

Total number of starts

2-14

SRT8

Load sum with hoist running time, eight power

1-1-3

Run time

Total running time

2-15

SWPHC%

SWP% value calculated with hoist cycles

1-1-4

Cycles

Total number of hoisting cycles.

2-16

SL1

Load sum with hoist cycles, the first power (mean load)

1-1-5

Mean load

Average of the handled load

2-17

SL3

Load sum with hoist cycles, the third

1-1-6

Br SWP%

Remaining Safe Working Period of the brake in

percentage.

2-18

SL8

Load sum with hoist cycles, the eight power

1-1-7

MFI1 RT

Total hours of running time, when MFI1 input is closed.

2-19

Power on

The total power on time of the unit

1-1-8

MFI1 ST

Total amount of starts, when MFI1 input is closed.

2-20

Temp Index

Power on time of the unit, weighted with the unit’s

temperature

1-1-9

MFI2 RT

Total hours of running time, when MFI2 input is closed.

2-21

Max load

Maximum measured value of the load

1-1-10 MFI2 ST

Total amount of starts, when MFI2 input is closed.

3

Load setup Load calibration menu. Accessible password level 2

1-2

Measure

Measurement menu

3-1

Cal. Motor

Load calibration when the motor torque based load

measurement is selecte. See chapter “Load

calibration sequence with motor torque”.

1-2-1

Act. Load

The measured actual load value.

3-2

MC values

Load calibration values for the motor torque method

1-2-2

Temp 1

Temperature measured at thermistor input 1.

3-2-1

Load 1

The higher test load’s value

1-2-3

Temp 2

Temperature measured at thermistor input 2.

3-2-2

Mhs1

Motor torque for hoisting in slow speed, with load.

1-2-4

Supply L1

Line voltage of phase L1.

3-2-3

Mhf1

Motor torque for hoisting in fast speed, with load 1.

1-2-5

Supply L2

Line voltage of phase L2.

3-2-4

Mls1

Motor torque for lowering in slow speed, with load 1.

1-2-6

Supply L3

Line voltage of phase L3.

3-2-5

Mlf1

Motor torque for lowering in fast speed, with load 1,

1-2-7

Motor I1

Motor current of phase L1.

3-2-6

Load 2

The lower test load’s value.

1-2-8

Motor I2

Motor current of phase L2.

3-2-7

Mhs2

Motor torque for hoisting in slow speed, with load 2.

1-2-9

Motor I3

Motor current of phase L3.

3-2-8

Mhf2

Motor torque for hoisting in fast speed, with load 2.

1-2-10 Ain1 value

Measured voltage at analogue input AIN1.

3-2-9

Mls2

Motor torque for lowering in slow speed, with load 2.

1-2-11 Ain2 value

Measured voltage at analogue input AIN2.

3-2-10 Mlf2

Motor torque for lowering in fast speed, with load 2.

1-2-12 Ain3 value

Measured voltage at analogue input AIN3.

3-3

Cal. Sens

Load calibration when the sensor based load

measurement is selected. See chapter “Load

calibration sequence with the load sensor”.

1-2-13 Int. temp

Internal temperature of the unit.

3-4

SC values

Load calibration values for the load sensor method

1-2-14 Input

Indicates the status of the inputs: HIN, LIN, FIN, MFI1 &

MFI2.

3-4-1

Load 1

The higher test load value.

1-2-15 Output

Indicates the status of the outputs: HOUT, LOUT,

FOUT, RS & ROUT.

3-4-2

Input 1

The load measurement voltage in the analogue input

Ain1 corresponding to the higher test load

1-2-16 Supply f

Supply voltage frequency (50 or 60Hz)

3-4-3

Load 2

The lower test load value

1-3

Min/Max

Minimum / maximum value menu

3-4-4

Input 2

The load measurement voltage in the analogue input

Ain1 corresponding to the lower load

1-3-1

Min supply

Minimum measured value of the supply line voltage

RMS.

3-5

OL protect

Set to “OFF” to temporarily by-pass of the overload

protection

1-3-2

Max supply Maximum measured value of the supply line voltage

RMS.

4

Start-up

Start- menu. Accessible password level 4

1-3-3

Min Int. T

Minimum measured value of the internal temperature of

the unit.

4-1

MFI1

Multi-Functional Input 1 parameters

1-3-4

Max Int. T

Maximum measured value of the internal temperature of

the unit.

4-1-1

MFI1 oper.

Selects the function of MFI1:

2

Monitor 2

Read only menu for advanced condition monitoring

values and measured values. Accessible password

level 3

4-1-2

MFI1 IntL

Intermediate load limit value

2-1

SW version Software version of the unit

4-1-3

MFI1 2OLL

The second load

2-2

RT slow

Total run-time in slow speed

4-1-4

MFI1 CintL

Bridge intermediate load limit value.

2-3

RT fast

Total run-time in fast speed

4-2

MFI2

Multi-Functional Input 2 parameters

2-4

No. OT

Total number of hoist motor overtemperature incidents.

4-2-1

MFI2 oper.

Selects the function of MFI2:

2-5

No. OL

Total number of overload incidents

4-2-2

MFI2 IntL

The (second) intermediate load limit value

2-6

E-stops

Total number of emergency stops incidents

4-2-3

1+2 IntL

The third intermediate load limit value

2-7

ST up

Total number of starts in up direction

4-2-4

MFI2 2OLL

The second load limit

2-8

ST down

Total number of starts in down direction

4-2-5

MFI2 CintL

The (second) bridge intermediate load limit value

2-9

ST fast

Total number of starts to fast speed (counts in two

speed control only)

4-2-6

1+2 CintL

The third bridge intermediate load limit value

2-10

Max ED

Maximum value of the calculated ED percentage