R&M Materials Handling HOIST MONITORS User Manual

Page 22

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

22/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

Fault means that one (or more) of the supervised safety features values exceeds the limit. Running the

hoist is restricted.

For Run or Fault supervision, it is possible to connect an external indication device like a horn or

lamp to the relay output. Relay output must be programmed to the desired function “OK” or “Ready”

5.2 Overload protection

The overload protection can be done in two ways, either with motor torque calculation or by using a load

sensor. Regardless which system is used, the hoist-monitoring unit will prevent the hoisting motion when

the measured load exceeds 110% of the rated load for a period of time. A filtering delay is built in to

assure trouble-free lifting of a rated load. The overload protection is reset when the measured load

decreases to 80% of the rated load.

The overload protection reacts faster than the display updates the measured values. Therefore it

may happen that the movement is stopped although the display indicates a load less than 110% of

the rated load.

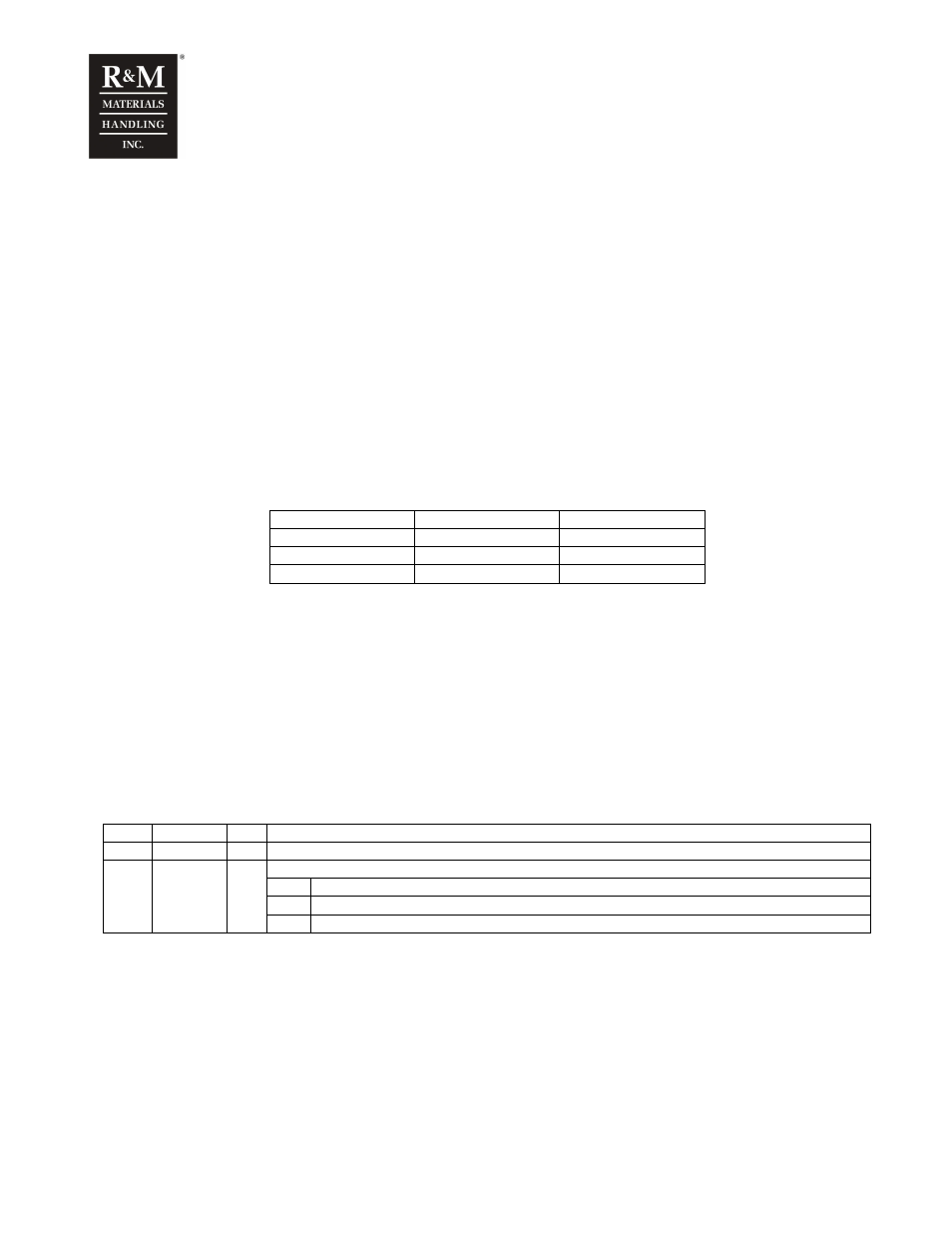

Overload level

Filtering time

Run-down time

140%

60 ms

~100 ms

125%

200 ms

~250 ms

110%

1000 ms

~1050 ms

The motor torque calculation system uses the motor voltage, current and temperature to calculate the

motor torque and converts this into load information. This system cannot be used in combination with

frequency converters, and can only measure the load when the motor is running. In addition to the

overload protection, the hoist-monitoring unit also supervises the brake. When the calculated load value

descends under -50% of the rated load during lowering, it indicates that the brake did not open. Lowering

the hook is prevented, but lifting is still allowed.

Motors driven by a frequency converter are always equipped with a load sensor for load measurement.

Systems using a strain gauge type of sensor are also equipped with a load sensor amplifier to amplify the

signal coming from the sensor. In case a Hall-type of sensor is used, the load sensor amplifier is not

needed.

Param. Name

Value Description

4-7

Load param

Load calculation parameters

Selects the load calculation method:

NU

Not used, the display show all time to 0,0t

Motor Motor torque calculation. Refer to chapter “Overload protection – Motor torque” of this manual

4-7-1

Load meas.

Sens. Load sensor measurement . Refer to chapter “Overload protection – Load sensor” of this manual

Load measurement tolerance is ±10% of nominal load by use motor torque calculation system and

load measurement tolerance is ±5% of nominal load by use load sensor.