R&M Materials Handling HOIST MONITORS User Manual

Page 75

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

75/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

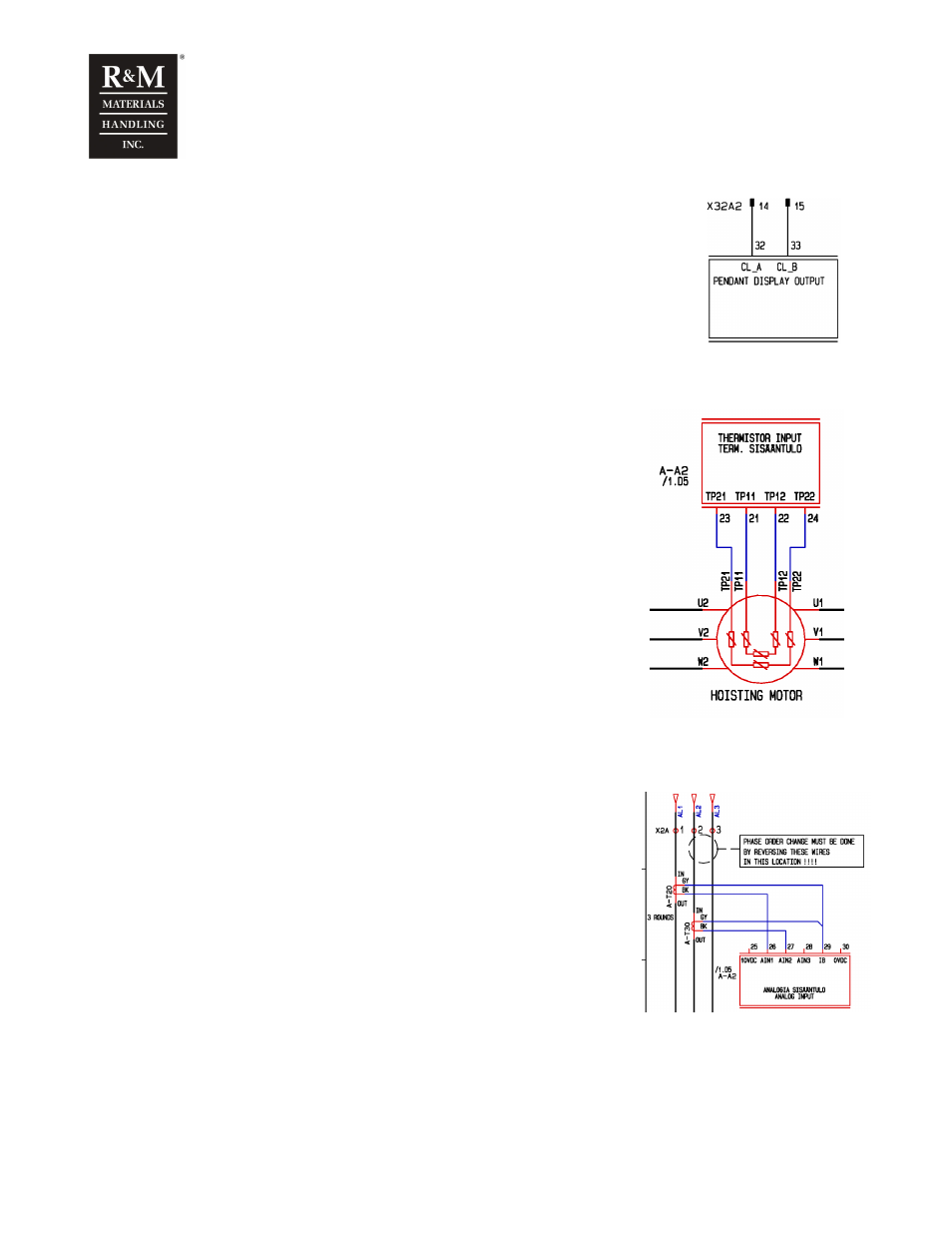

14.3 Blank display

•

If display shows “blank”, check that display location selection switch

position is right, logal (LOC) or remote (REM), in the monitoring unit.

•

Check the connections from the unit to the display

•

Change the remote display cables connections for terminals 32 and 33

14.4 The temperature sensors (NTC-wiring)

If the NTC-sensor is selected and the temperature sensor is not

connected, the values for parameters 1-2-2 “Temp 1” and/or

parameter 1-2-3 T2 are about -50

o

C.

Check that temperature sensor 1 (slow speed) is connected across

terminal 21 and 22 and that the slow speed temperature is

measured with channel T1 (parameter 4-7-6 is set to “T1”)

When driving in slow speed, the value of parameters 1-2-2 “Temp 1”

should increase.

Check that temperature sensor 2 (fast speed) is connected across

terminal 23 and 24 and that the fast speed temperature is measured

with channel T2 (parameter 4-7-7 is set to “T2”).

When driving in fast speed, the value of parameters 1-2-3 “Temp 2”

should increase.

Reverse the connections of terminals 21-22 and 23-24 when

needed, and carry out the calibration procedure again.

14.5 Current transformers

•

Check that the current transformer AT-20 is connected across

terminals 26 and 29

•

Check that the current transformer AT-30 is connected across

terminals 27 and 29

•

The grey wires of both transformers must be connected to

terminal 29.

If one of current transformers is connected wrong, it can be checked

with parameters 1-2-9 “Motor I3”. In that case, parameter 1-2-9 has

a different value than parameters 1-2-7 “Motor I1” and parameter 1-

2-8 “Motor I2”, whereas all three should have the same value. The

most common fault is that the input wire goes trough the

transformers in the wrong direction.